Table of Contents

Introduction

Rapid annealing furnaces (RTA furnaces) are essential tools in the research and development of advanced materials and semiconductor technology.

These high-temperature systems enable precise and controlled heating processes, ensuring improved material properties, defect reduction, and enhanced device performance.

As industries continue to push the boundaries of nanotechnology, microelectronics, and energy materials, the demand for rapid thermal processing solutions has increased significantly.

What Is a Rapid Annealing Furnace?

A rapid annealing furnace is a specialized high-temperature processing system designed to heat materials rapidly and maintain uniform thermal conditions for short durations.

Unlike conventional furnaces, RTA furnaces minimize thermal exposure, preventing undesirable diffusion effects while preserving material integrity. These furnaces operate at temperatures ranging from 200°C to over 1200°C, depending on the specific application.

Key Applications of Rapid Annealing Furnaces

1. Semiconductor Device Fabrication

Semiconductor manufacturing requires precise thermal treatments to optimize the electrical and structural properties of materials. Rapid annealing furnaces play a crucial role in:

- Dopant Activation: Enhancing the electrical properties of semiconductors by activating implanted ions without excessive diffusion.

- Silicon Wafer Processing: Improving crystallinity and reducing defects in silicon wafers used for integrated circuits (ICs).

- Oxidation and Nitridation: Enhancing surface passivation and insulating properties by forming high-quality oxide and nitride layers.

2. Advanced Thin Film and Coating Development

RTA furnaces support the rapid thermal processing of thin films used in electronic and optical devices, including:

- Metal Oxide Films: Enhancing the properties of transparent conductive oxides (TCOs) for displays and solar cells.

- Dielectric Layer Annealing: Improving the electrical insulation of thin films in capacitors and gate dielectrics.

- Protective Coatings: Strengthening mechanical and chemical resistance in high-performance coatings.

3. Graphene and 2D Materials Research

In the field of nanomaterials, rapid annealing furnaces contribute to the synthesis and modification of graphene, MoS₂, and other 2D materials:

- Graphene Growth: Facilitating the chemical vapor deposition (CVD) of high-quality graphene for flexible electronics and sensors.

- Defect Healing: Repairing structural imperfections to enhance electrical and thermal conductivity.

- Surface Functionalization: Modifying surface properties to tailor material performance for specific applications.

4. High-Performance Ceramic and Composite Material Processing

The development of advanced ceramics and composite materials benefits from rapid thermal processing due to:

- Crystallization Control: Enhancing phase transitions for improved mechanical strength and thermal stability.

- Sintering Optimization: Achieving higher densification rates while maintaining fine-grained microstructures.

- Surface Modification: Improving adhesion, wear resistance, and chemical stability in functional ceramics.

5. Energy Storage and Photovoltaic Applications

The demand for efficient energy storage solutions has driven research in lithium-ion batteries and perovskite solar cells, where RTA furnaces are used for:

- Electrode Material Processing: Enhancing the performance of cathodes and anodes in rechargeable batteries.

- Perovskite Solar Cell Fabrication: Improving film crystallinity for higher photovoltaic efficiency.

- Solid-State Electrolyte Development: Advancing next-generation battery technologies with improved ionic conductivity.

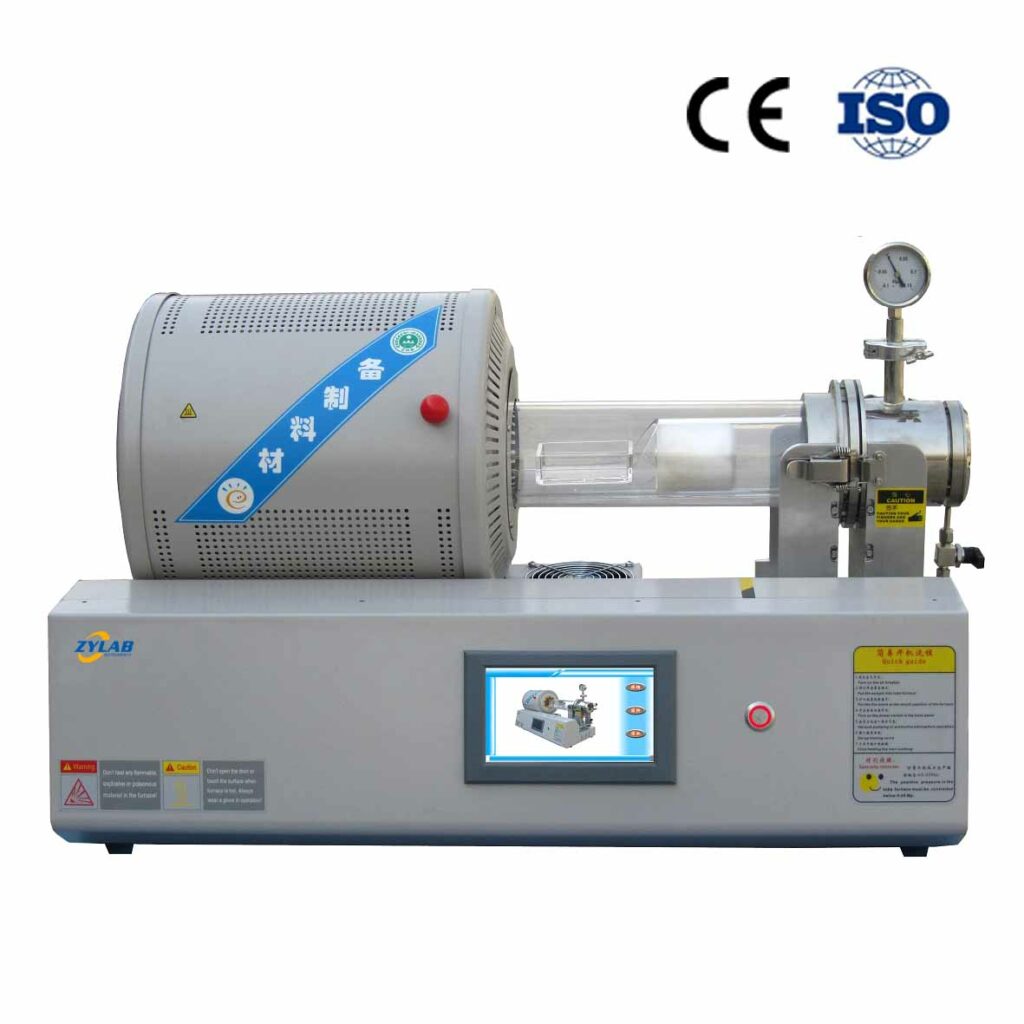

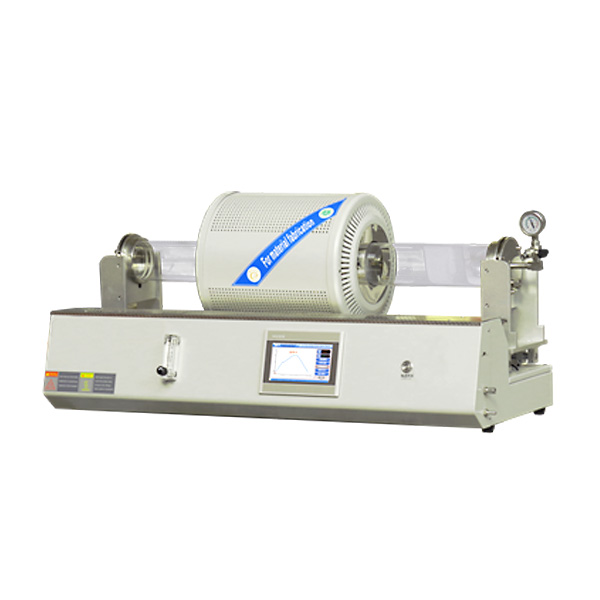

Why Choose ZYLAB Rapid Annealing Furnace?

ZYLAB’s rapid annealing furnaces offer superior temperature control, uniform heating, and customizable features that cater to the diverse needs of researchers and semiconductor manufacturers. Key advantages include:

1. Ultra-Fast Heating and Cooling Rates

- ZYLAB RTA furnaces max speed of temperature rising up to 100.C/S, ensuring minimal thermal diffusion and precise processing.

- Rapid cooling prevents unwanted material degradation and enhances uniformity.

2. Advanced Temperature Control and Uniformity

- High-precision PID controllers ensure temperature stability and repeatability.

- Infrared or halogen lamp heating provides excellent temperature uniformity across the sample surface.

3. Versatile Atmosphere Control

- Supports inert, reducing, and reactive gas atmospheres to accommodate various material synthesis and semiconductor doping processes.

- Optional vacuum capability ensures contamination-free annealing for sensitive materials.

4. User-Friendly Interface and Automation

- Intuitive touchscreen controls enable precise programming of temperature profiles.

- Automated sample handling ensures repeatable processing and high throughput.

Conclusion

Rapid annealing furnaces play a vital role in advancing materials science and semiconductor technology by enabling precise, high-speed thermal processing. Their applications span semiconductor fabrication, thin film development, graphene research, ceramic processing, and energy storage technologies.

For more information on ZYLAB’s rapid annealing furnaces, contact us today to find the perfect solution for your research and production needs.

Share this entry

You might also like