What is a sieve shaker?

A sieve shaker is a laboratory instrument used for particle size analysis, separation, and classification of granular materials.

It uses a series of sieves with different mesh sizes to divide particles into various size fractions, widely applied in quality control, research, and product development across industrial and laboratory settings.

To watch the laboratory sieve shaker video, please click here!

Working Principle

The core principle of a sieve shaker is vibration screening.

The device uses a vibrating motor to generate vibrations that are transferred to the base, which then transmits them to the standard test sieves placed on top. When material is added to the sieve stack, smaller particles pass through the sieve mesh to the lower layers, while larger particles remain on the upper layers. This process continues layer by layer, resulting in each sieve layer retaining only particles of the same size.

This classification method enables precise separation by particle size and provides data support for subsequent particle size distribution analysis.

Advantages

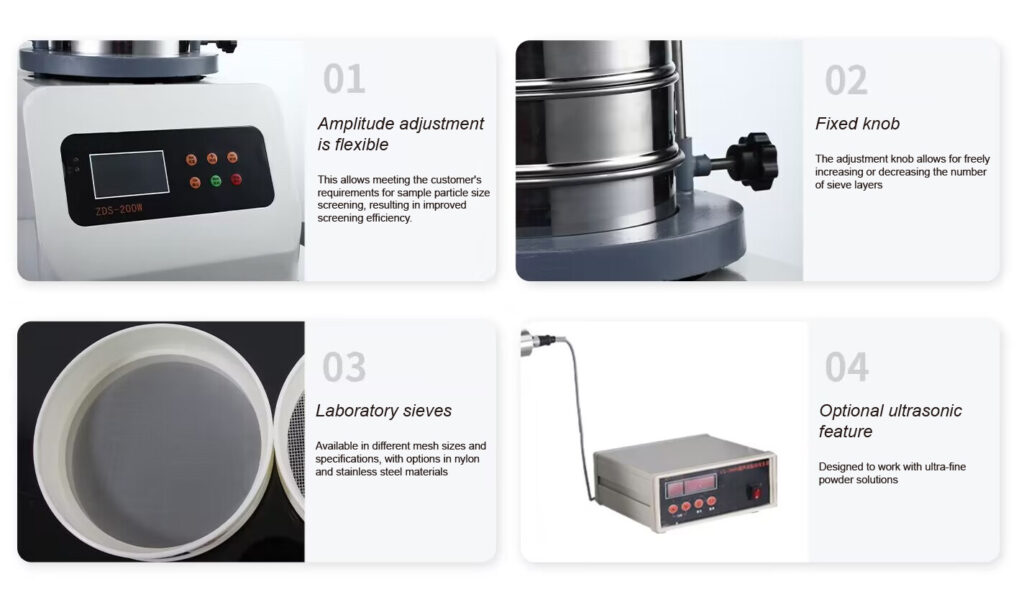

Sieve shakers offer numerous advantages, making them essential equipment in laboratories and industries:

- Efficiency: Well-designed to quickly and effectively sieve various powders or liquids.

- Durability: Built with high-quality materials, ensuring long-term use.

- Compactness: Small in size, saving space, and easy to move and operate.

- Multi-Layer Sieving: Accommodates up to 7 sieve layers, accurately separating granular materials into 2 to 7 particle size fractions.

- Automatic Timing: Built-in timer for convenient operation, ensuring experimental repeatability.

- Low Noise: Operates quietly, ideal for laboratory environments.

- Diverse Sieve Materials: Available with nylon or stainless steel sieves to meet different sample requirements.

- Ultrasonic Option: Optional ultrasonic function for sieving ultra-fine powders.

Application of Sieve Shaker

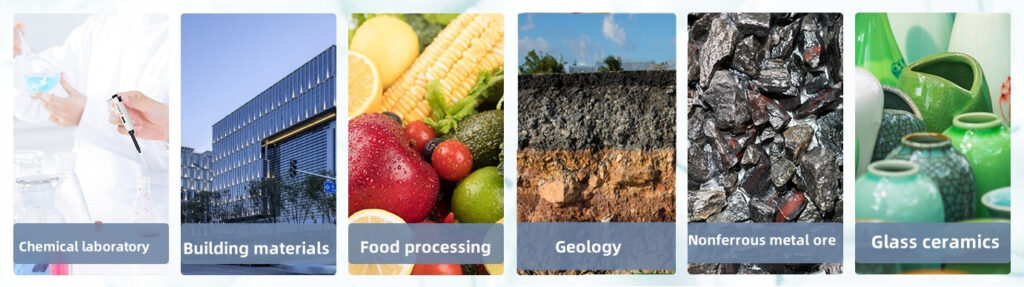

Sieve shakers have a wide range of applications across multiple industries, catering to different particle material screening needs:

- Pharmaceutical Industry: Used for screening drug powders and quality control, ensuring consistent particle size distribution in drug formulations, which affects drug release and absorption.

- Chemical Industry: Applied for grading powders and particles to ensure size consistency in chemical batches; additionally, in catalyst screening, it ensures catalysts have appropriate particle sizes to optimize reaction rates.

- Food Industry: Utilized for sieving ingredients such as flour, spices, and sugar to ensure uniform particle size, thereby enhancing product quality.

- Construction Industry: Screens aggregates like sand and gravel for concrete and asphalt production; the particle size distribution of cement and lime affects their mixing effectiveness.

- Mining and Metallurgy: Ensures size consistency of processed raw materials during the grading of ores, minerals, and coal.

- Environmental Science: In soil analysis, sieve shakers determine the size distribution of soil particles, assisting in the study of soil structure in agriculture and the environment.

- Cosmetic Industry: Used for particle size grading and quality control of powdered cosmetics, ensuring consistency in raw materials and final products.

- Ceramics and Glass: Screens raw materials to ensure uniform particle size in ceramics and glass products.

- Nanotechnology: Critical for particle size analysis of nanoparticles in the research and development of nanomaterials, ensuring precise size distribution.

- Academic and Research Laboratories: Sieve shakers are used for particle size analysis and classification studies of various materials, helping researchers and students understand the principles of material separation.

Choosing a Sieve Shaker

When selecting a sieve shaker, you can refer to the following points to ensure the equipment meets your actual needs:

Sieve Diameter

Choose an appropriate sieve diameter based on the particle size range of the samples. Common specifications include 20mm, 30mm, 40mm, and 60mm.

Number of Sieve Layers

The sieve shaker supports configurations of up to 7 layers of sieves. Choose the number of layers based on the complexity of the sample’s particle sizes.

Sieve Material

Select the appropriate sieve material based on the chemical properties of the samples. Nylon sieves are suitable for general materials, while stainless steel sieves are appropriate for high-temperature or corrosive samples.

Ultrasonic Function

If sieving extremely fine powders, consider models with ultrasonic functionality to prevent particle clogging and further enhance sieving accuracy.

As an efficient laboratory tool, the sieve shaker is suitable for various particle size analysis and screening needs. A careful evaluation of specific requirements in experiments or production will help optimize screening efficiency and improve the level of quality control for products.

You have any questions about sieve shakers, please contact us immediately. We provide free quotes for all sieve shakers!

Share this entry

You might also like