Table of Contents

Introduction

In the quest for cleaner and more efficient energy storage solutions, solid-state batteries have emerged as promising alternatives to traditional lithium-ion batteries. These advanced batteries offer higher energy densities, improved safety, and longer lifespans.

However, their development and commercialization face significant challenges, particularly in the optimization of materials and manufacturing processes.

Laboratory furnaces play a crucial role in addressing these challenges by enabling precise control over the synthesis and characterization of battery materials.

Understanding Solid-State Batteries

Solid-state batteries differ from conventional lithium-ion batteries primarily in their use of solid electrolytes instead of liquid or gel electrolytes.

This structural difference offers several advantages, including enhanced safety, wider operating temperature range, and potential for higher energy densities.

However, the successful implementation of solid-state batteries requires the optimization of various components, including electrodes, electrolytes, and interfaces.

Role of Laboratory Furnaces

Laboratory furnaces serve as indispensable tools in the research and development of solid-state batteries. Their ability to provide controlled heating and cooling environments enables scientists and engineers to precisely synthesize, process, and characterize battery materials. Here are some key ways in which laboratory furnaces contribute to the advancement of solid-state battery technology:

Material Synthesis:

Laboratory furnaces are used to synthesize battery components such as cathodes, anodes, and solid electrolytes.

These furnaces allow researchers to precisely control parameters such as temperature, atmosphere, and heating rate, thereby optimizing the properties of the synthesized materials.

For example, high-temperature furnaces are essential for the fabrication of ceramic solid electrolytes, which require sintering at elevated temperatures to achieve the desired density and conductivity.

Thin Film Deposition:

Many solid-state battery architectures require the deposition of thin films to form electrode layers and interfaces.

Laboratory furnaces equipped with techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) enable the controlled growth of thin films with uniform thickness and composition. By adjusting deposition parameters within the furnace, researchers can tailor the microstructure and electrochemical properties of the deposited films to meet specific performance requirements.

Characterization Studies:

Laboratory furnaces are also utilized for conducting various characterization studies on battery materials.

Techniques such as differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and X-ray diffraction (XRD) are commonly performed using furnaces to investigate the thermal, structural, and phase evolution behaviors of materials under different conditions. These studies provide valuable insights into the stability, reactivity, and performance of solid-state battery components.

Electrode Fabrication:

In addition to material synthesis, laboratory furnaces are employed in the fabrication of battery electrodes.

Processes such as electrode pressing, calendaring, and heat treatment are carried out using specialized furnaces to optimize the morphology, porosity, and conductivity of electrode materials. By controlling parameters such as pressure, temperature, and duration, researchers can enhance the electrochemical performance and cycling stability of solid-state battery electrodes.

Relevant Laboratory Furnaces

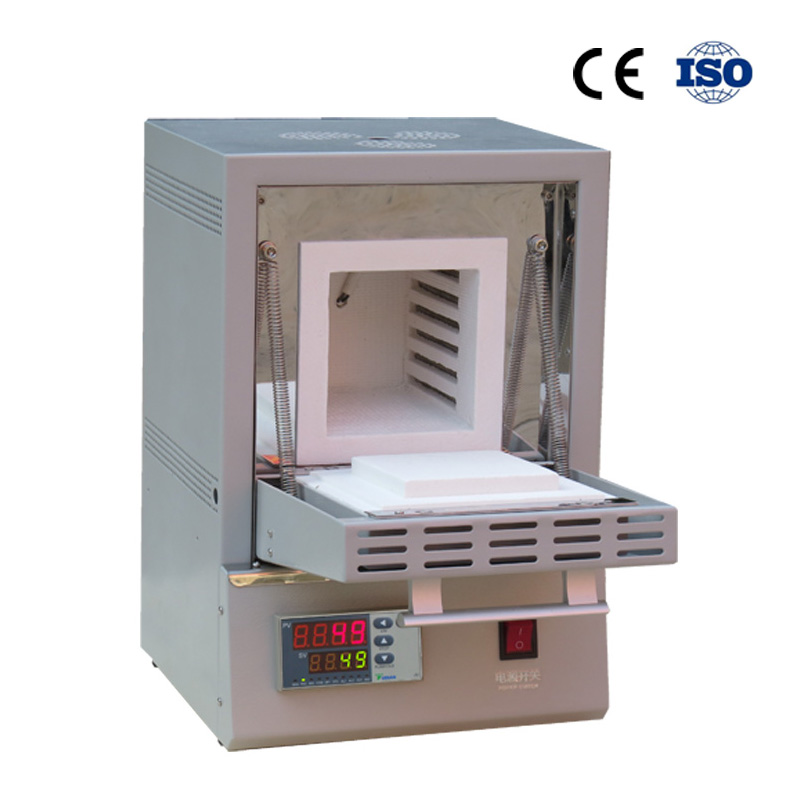

The ZYLAB furnace has been used in multiple solid-state battery research laboratories, providing researchers with precise temperature control and a stable experimental environment.

Conclusion

Laboratory furnaces are invaluable assets in the development of solid-state batteries, offering researchers the tools and capabilities needed to overcome critical challenges and unlock the full potential of this transformative technology.

By leveraging the precise control and characterization afforded by laboratory furnaces, scientists and engineers are paving the way for safer, more efficient, and environmentally sustainable energy storage solutions.

As advancements in furnace technology continue to drive innovation in solid-state battery research, the future holds great promise for the realization of next-generation energy storage systems.