Table of Contents

Introduction

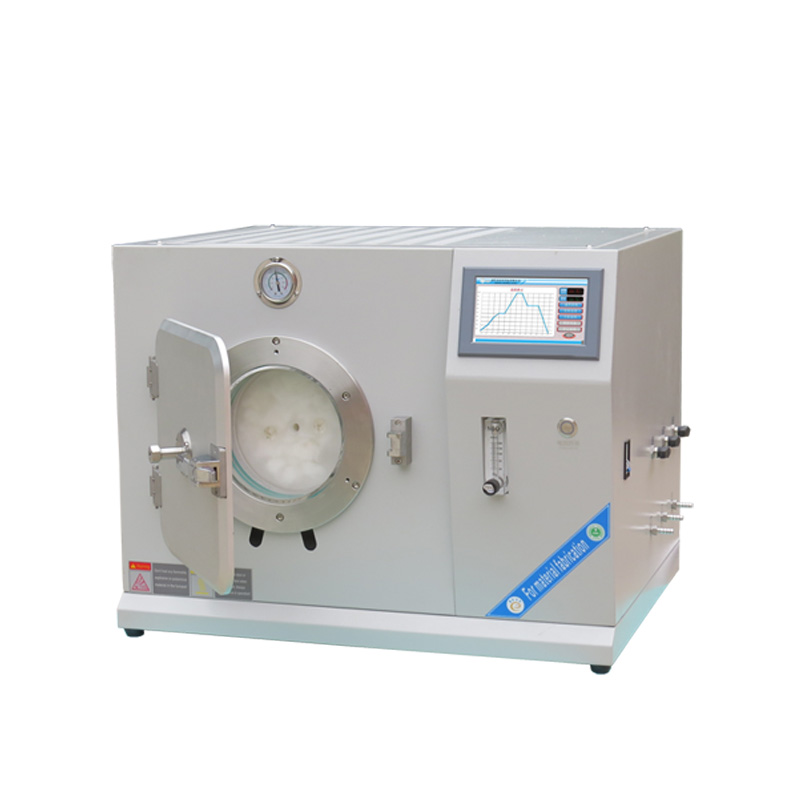

In the field of materials science and metallurgy, hydrogen reduction furnaces play a critical role in the purification and reduction of precious metals.

These furnaces provide a controlled high-temperature environment under a hydrogen atmosphere, facilitating the removal of oxides and other impurities from valuable metals such as gold, silver, platinum, palladium, and rhodium.

Working Principle of Hydrogen Reduction Furnaces

A hydrogen reduction furnace operates by introducing high-purity hydrogen gas into the furnace chamber, which reacts with metal oxides at elevated temperatures. The reaction typically follows the equation:

MO + H₂ → M + H₂O

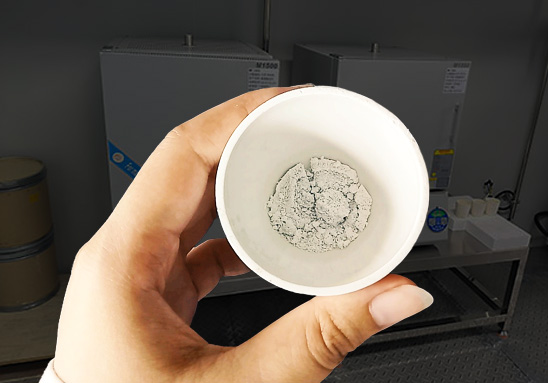

where MO represents the metal oxide, and M is the purified metal. The generated water vapor is subsequently removed, ensuring a clean and efficient reduction process. The furnace’s precise temperature control and inert environment prevent oxidation, leading to high-purity metal recovery.

Applications in Precious Metal Purification and Reduction

1. Purification of Platinum Group Metals (PGMs)

Platinum, palladium, and rhodium are widely used in catalytic converters, electronics, and chemical industries. Hydrogen reduction furnaces are essential for refining these metals by eliminating oxygen, sulfur, and other contaminants, thereby enhancing their purity and performance.

2. Gold and Silver Refining

Gold and silver are often alloyed with base metals, which need to be separated for high-purity applications. Hydrogen reduction furnaces help remove oxides and trace impurities from these noble metals, ensuring superior quality for industrial and investment purposes.

3. Regeneration of Spent Catalysts

Industries utilizing precious metal-based catalysts, such as petrochemicals and pharmaceuticals, require periodic regeneration to restore catalytic activity. Hydrogen reduction furnaces effectively remove surface oxidation and contaminants, prolonging catalyst lifespan and reducing waste.

4. Nanomaterial Synthesis and Research

Hydrogen reduction furnaces are extensively used in research institutions and laboratories for synthesizing metal nanoparticles with controlled size and high purity. This application is critical in developing advanced materials for electronics, energy storage, and biomedical fields.

Advantages of ZYLAB Hydrogen Reduction Furnaces

- High Purity Processing: Eliminates oxides and other impurities efficiently.

- Precise Temperature and Atmosphere Control: Ensures optimal reduction conditions.

- Eco-Friendly Operation: Hydrogen reduction is a cleaner alternative to chemical-based purification methods, reducing harmful emissions.

- Versatility: Suitable for various precious metals and industrial applications.

- Customizable Configurations: Adaptable for different scale operations, from laboratory research to industrial-scale processing.

Conclusion

Hydrogen reduction furnaces are indispensable in the purification and reduction of precious metals, offering a clean, efficient, and high-purity refining process.

Their applications in platinum group metal refining, gold and silver purification, catalyst regeneration, and nanomaterial research make them a valuable tool for both industrial and scientific fields.

As technological advancements continue, the role of hydrogen reduction furnaces in sustainable and high-efficiency metallurgy will further expand.

For more information about hydrogen reduction furnaces and customized solutions, feel free to contact us.

Share this entry

You might also like