Table of Contents

What is High-purity Alumina Tube (Product)

High-purity alumina products refer to various products made from high-purity aluminum oxide (Al2O3) as raw materials. This material is widely used in various high-temperature industrial processes due to its excellent high-temperature resistance, chemical stability, and electrical insulation properties.

High-purity alumina tubes are key components used in high-temperature furnaces, typically employed to withstand extreme high-temperature conditions such as chemical reactions, heat treatment, sintering, and smelting processes.

Advantages and Disadvantages of Alumina Products

Advantages: High purity, dense structure, acid and alkali resistance, operating temperature ≤1650℃, unaffected by reducing atmospheres, can be used in oxidizing environments.

Disadvantages: Poor thermal shock resistance, not resistant to rapid cooling or heating.

High-purity alumina tubes find wide applications in fields such as semiconductor manufacturing, optical glass processing, metal sintering, chemical reactions, etc., because they can provide a stable high-temperature environment without contaminating the processes.

High-purity alumina tubes (or alumina products) are consumables in use, and while utilizing the superior characteristics of the products, we must adhere to the inherent properties of alumina material. Careful operation is required during use, as improper operation can cause the tubes or crucibles to crack or explode.

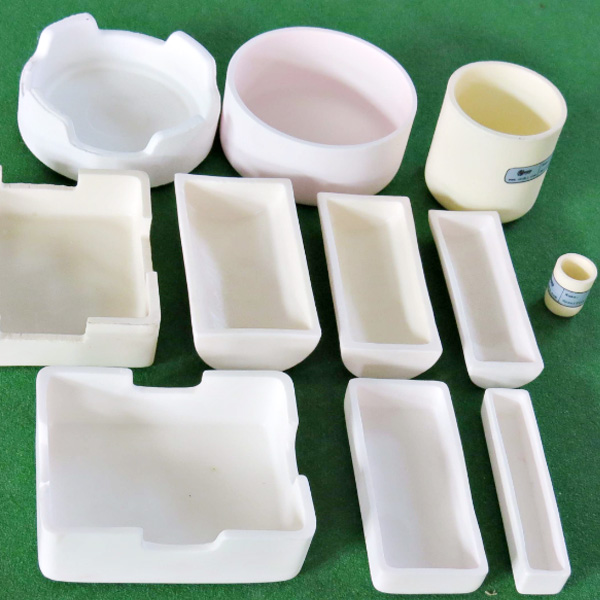

High-purity alumina products provided by ZYLAB

Alumina Tube Sizes(Dia*L)

50*700mm 50*1000mm 50*1200mm 50*1400mm

60*700mm 60*800mm 60*1000mm 60*1200mm

80*1000mm 80*1200mm 80*1400mm 80*1500mm

100*1000mm 100*1200mm 100*1200mm

Other sizes, can be customized according to demand.Feel free to contact our technical staff if you have any questions.

Analysis of Reasons for Furnace Tube or Crucible Rupture

Large Temperature Difference:

1. When using high-temperature furnace tubes (or products), it is best to control the heating and cooling rate at 5 degrees/minute, slower being better. Rapid cooling or heating is one of the main reasons for the fracture of alumina furnace tubes. The operating temperature under atmospheric pressure should be ≤1650°C.

2. Always keep the inside of the tube clean. Clean the inner wall of the furnace tube promptly after use, and do not leave any residual samples in the tube to avoid chemical reactions. Impurities should be avoided in the high-temperature zone, especially non-metallic mineral raw materials containing metal debris and K2O, Na2O, CaO, SiO2, as they may form low-temperature eutectics and cause damage or cracking of the alumina tube.

3. When taking samples, the furnace temperature should be <150 degrees, and the sample should be slowly pushed from the edge to the center.

High-temperature sampling and sampling are the main causes of alumina tube fracture. Do not touch the high-temperature furnace tube with a low-temperature object, and avoid inserting the alumina tube directly into the high-temperature furnace chamber.

During cooling, the temperature should be gradually reduced to 300 degrees and then naturally cooled. Control the heating and cooling rate to about 5°C, and do not cool with air or indirectly with cooling water.

Localized rapid cooling or heating of high-purity alumina furnace tubes should be avoided, especially when hot alumina tubes are placed directly on refractory bricks or refractory fiber blankets at room temperature, as this can easily cause them to crack.

Avoid large temperature gradients when moving high-heat-capacity sintered materials against the walls of alumina furnace tubes. If movement is necessary, keep the temperature gradient within 200°C.

4. In places where ventilation is needed, the airflow should not be too high, ideally at 5-60 bubbles per minute, to avoid excessive temperature differences in the furnace tube leading to rupture. At high temperatures, the amount of bubbles will increase due to gas expansion. Do not reduce the air intake to avoid the siphoning of water into the furnace tube at the exhaust end during cooling due to reduced air intake, causing the furnace tube to rupture.

5. Sintered materials containing a large amount of water vapor need to adjust the furnace body, lowering the exhaust end to allow condensation to drain. Avoid the rupture of the furnace tube caused by the cold and hot cycle of condensate at the exhaust end.

Gravity Deformation:

When using high-temperature alumina furnace tubes, support frames must be added on both sides of the tube to prevent tube breakage due to gravity deformation.

Other Reasons:

1. Samples burned inside alumina furnace tubes, especially those to be burned at around 1300°C, should have low moisture content (moisture content refers to adsorbed water, crystalline water, and water generated during heating). Samples with high moisture content are recommended to be pre-burned at around 120°C to remove moisture before being placed in alumina furnace tubes for sintering reactions.

2. Newly purchased furnace tubes should be baked once at a heating rate of 5°C/min to 1300°C and then used for work to eliminate stress and contaminants.

3. It is recommended not to raise or lower the temperature too quickly, with heating and cooling rates of 5-8°C/min. In principle, the larger the size of the furnace tube and the higher the operating temperature, the slower the heating and cooling rates should be. (Be sure to set the cooling rate. Do not stop the furnace directly at high temperature for cooling. The rapid cooling at high temperature can easily cause the furnace tube to rupture.)

4. Recommended heating and cooling rates: ≤5°C/min below 500°C; ≤10°C/min between 500-800°C; ≤5°C/min between 800-1600°C.

5. For the uniformity of the temperature zone and the protection of sealed fittings, the position of the tube plug (or reflector) inside the furnace tube should preferably not overlap with the position of the external insulation cotton (or heat insulation support). Misalignment will reduce the temperature gradient changes and correspondingly increase the life of the alumina tube.

6. High-purity alumina furnace tubes are brittle materials, and their service life varies greatly depending on different usage conditions and process methods, including operating temperature, heating and cooling rates, atmosphere, volatile sintered materials, and ambient temperature. It is hoped that users can summarize a set of operation specifications that are most suitable for their own process characteristics.

Analysis of Furnace Tube Deformation Causes

1. Long-term use at temperatures exceeding 1600 degrees at room temperature will cause the furnace tube to soften due to the softening exchange state, leading to bending deformation due to gravity. After a full firing at high temperature, rotate the furnace tube 180° before firing again.

2. When the temperature exceeds 1500°C for a long time, the furnace tube gradually softens. It should be used under normal pressure (or in a flowing protective atmosphere) as much as possible.

When the absolute positive pressure in the furnace tube is ≥0.15 MPa, it will cause the furnace tube to bulge outward.If the furnace tube is evacuated, deformation will occur inward when the reverse pressure is ≤0.05 MPa.