An alumina plate and stand are both components made from alumina, also known as aluminum oxide (Al2O3), which is a ceramic material renowned for its hardness, high-temperature stability, and resistance to chemical corrosion and wear.

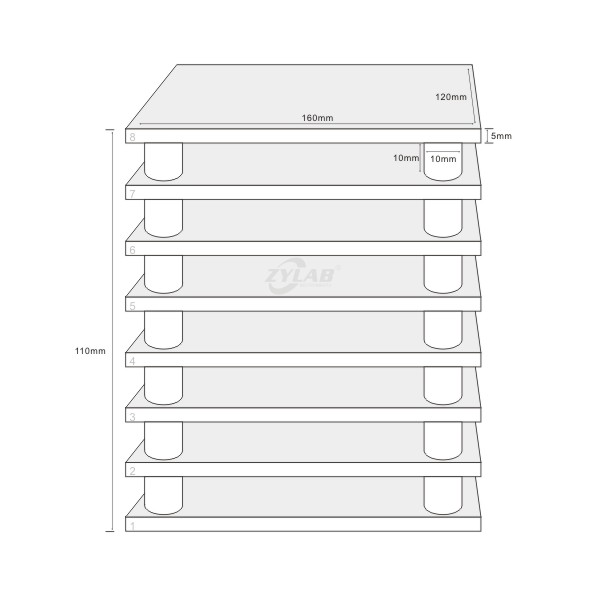

An alumina plate is a flat piece of material made from alumina.An alumina stand is a smaller, often thicker, piece of alumina used primarily for support and cushioning in high-temperature and high-stress environments.

When used together in furnace furniture, alumina plates and stands create a robust solution for supporting and separating items being fired in the furnace:

Serve as shelves or barriers to hold items during firing, providing a flat, stable surface.

Act as spacers or supports between plates or other components, ensuring even weight distribution and stability, and preventing direct contact that could lead to damage.

These components are essential in industries such as ceramics, electronics, and materials processing, where they ensure reliable performance under extreme conditions.

This type of plates and pads are made of extremely high-purity alumina. They typically have a purity higher than 99.9% alumina, with minimal impurities and dopants.

High-purity alumina exhibits excellent chemical stability and electrical insulation performance, making it widely used in applications that demand high material purity, such as semiconductor manufacturing, electronic devices, and optical components.

These plates and pads have relatively lower purity, typically ranging from 95% to 99.9%. They may contain more impurities and dopants, but still exhibit good mechanical properties, wear resistance, and high-temperature performance.

Industrial grade alumina is commonly found in general industrial applications, such as kiln furniture, chemical processing equipment, and refractory materials.

Application Environment: Consider the environmental conditions in which the plates and pads will be used, including temperature, pressure, chemical properties, and mechanical stress.

Size and Shape: Choose the appropriate size and shape of plates and pads according to specific application requirements. Consider factors such as thickness, length, width, and shape to ensure they meet the required support and separation needs.

Purity Requirements: Select alumina plates and pads with the appropriate purity level based on the application’s requirements and standards.

Cost-effectiveness: Balance the cost against performance.

Supply Reliability: Assess the reliability and delivery capabilities of suppliers to ensure timely access to the required plates and pads, and to guarantee product consistency and quality stability.

1. We offer a variety of standard sizes for alumina plates and pads for you to choose from.

2. We can design the optimal solution for you free of charge based on the space of your chamber and the size and quantity of the materials being fired.

3. We also offer various other alumina products, such as alumina crucibles, alumina grinding bowls, and alumina tubes.

4. We provide free quotations. Please feel free to contact us if you have any questions.

Notifications

Welcome to ZYLAB.

Ask us anyting :)