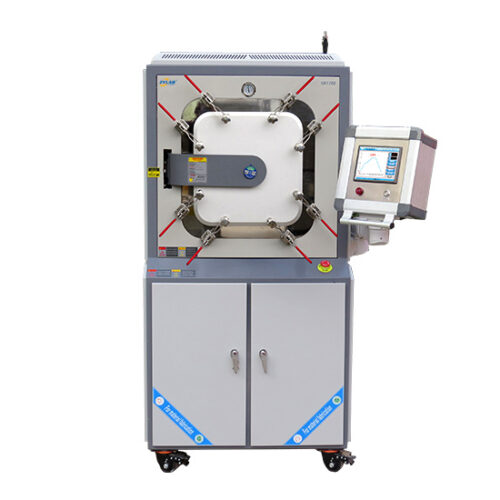

ZYLAB 1200°C Debinding Furnace

Introduction

ZYLAB 1200°C Debinding Furnace is a high-performance solution tailored for thermal post-processing of metal and ceramic parts produced via additive manufacturing. Engineered for precision binder removal under vacuum or controlled atmosphere, this furnace is ideal for applications that require mid-range temperature debinding and pre-sintering treatment.

It offers a cost-effective alternative to high-temperature systems, while maintaining high thermal uniformity, excellent process repeatability, and intuitive digital control — making it especially suitable for labs, research institutes, and pilot-scale production lines.

Key Features

-

1150°C Max Temperature

Perfect for binder burnout and low-temperature sintering in metal or ceramic-based AM parts. -

Dual Atmosphere Operation

Compatible with vacuum and inert gas environments (argon, nitrogen), ensuring clean and controlled processing. -

Precise PID Temperature Control

Advanced fuzzy logic controller with ±1°C accuracy and multi-step programmable profiles. -

Uniform Heating with High-Efficiency Insulation

Alumina fiber insulation and optimized heating layout deliver fast heating and uniform temperature distribution. -

User-Friendly Interface

Touchscreen operation, curve display, auto-start, and real-time data logging for easy, intelligent control. -

Built-in Safety System

Includes over-temperature protection, gas pressure monitoring, and cooling system safeguards. -

Customizable Chamber Design

Furnace chamber size and structure can be tailored based on specific application needs.

Applications of 1200°C Debinding Furnace

-

Binder removal of 3D printed metal components in Metal Fused Filament Fabrication (Metal-FFF) or Metal SLA.

-

Pre-sintering treatments for ceramics, including green body densification and phase stabilization.

-

Debinding of MIM-like parts before high-temp sintering.

-

Suitable for R&D, prototyping, and low-volume production.

Technical Specifications

| Model | VA1200-30 | |

| Power Supply | AC 380V, 12KW | |

| Maximum Temperature | 1150°C | |

| Continuous Working Temp | 1100°C | |

| Furnace Chamber Size | 300 × 300 × 400 mm | |

| Vacuum Level | ≤100 Pa | |

| Recommended Heating Rate | ≤20°C/min | |

| Temperature Accuracy | ±1°C | |

| Heating Element |  |

Acid- and Corrosion-Resistant Alloy Heating Wire |

| Control System |  |

|

| Optional Configuration |  |

Copper electrode feedthrough (vacuum-sealed, connects to external heating system) |

| Safety Notes |

|

|

| Support & Warranty | 1-year warranty (excluding consumables); lifetime technical support | |

FAQ – 1200°C Debinding Furnace

Q: What is the ZYLAB 1200°C Debinding Furnace used for?

A: It is designed for thermal post-processing of metal and ceramic parts made by additive manufacturing, particularly for debinding, low-temperature sintering, and pre-sintering under vacuum or inert gas.

Q: What types of 3D printed materials are compatible with this furnace?

A: The furnace is ideal for metal-polymer composite filaments (e.g. Metal FFF), ceramic green bodies, and other AM parts that require controlled binder removal or densification below 1200°C.

Q: Can the system store and record thermal process data?

A: Yes. It can store up to 20 temperature profiles and record key process data like temperature, power, and time. Data can be exported for analysis or documentation.

Q: Does this furnace require external cooling?

A: For high-temperature operation, connection to a water chiller is necessary to protect sealing components like silicone gaskets.

Q: Can the furnace chamber be customized?

A: Yes, ZYLAB offers customized chamber sizes and feedthrough options based on user requirements and sample dimensions.

For More Content

Please read our blog: Applications of Vacuum Furnaces in Materials Preparation: An In-Depth Guide

For More Options on Additive Manufacturing(3D Printing)

Please visit our website [Additive Manufacturing(3D Printing)]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]