Table of Contents

In recent years, the aluminum electrolysis industry has been under increasing pressure to improve efficiency, reduce carbon emissions, and adopt greener technologies.

One solution gaining significant attention is the laboratory molten salt electric heating furnace. While traditionally used in research and development, this advanced heating equipment is playing a crucial role in optimizing aluminum electrolysis processes, paving the way for low-carbon, energy-efficient aluminum production.

In this article, we explore the applications, advantages, and future trends of laboratory molten salt electric heating furnaces in the aluminum electrolysis sector.

What Is a Laboratory Molten Salt Electric Heating Furnace?

A molten salt electric heating furnace is a high-temperature laboratory device that utilizes molten salt as the heat transfer medium.

These systems are capable of maintaining uniform and stable high temperatures, typically ranging from 300°C to 1200°C, depending on the salt mixture used.

The high thermal conductivity and stability of molten salt make it ideal for applications requiring precise temperature control, including materials research, thermal treatment, and electrochemical processes.

Why Is Molten Salt Heating Important in Aluminum Electrolysis?

1. Enhanced Thermal Efficiency

Molten salt furnaces offer superior thermal conductivity compared to traditional air or resistance heating methods. This efficiency translates into faster heat-up times and more stable process temperatures, which are critical in aluminum electrolysis experiments.

2. Accurate Simulation of Industrial Conditions

Laboratory molten salt furnaces allow researchers to replicate industrial aluminum electrolysis conditions on a smaller scale. By fine-tuning temperature profiles and controlling the molten salt composition, scientists can optimize electrolyte formulations, study electrode behavior, and improve current efficiency.

3. Energy Efficiency and Sustainability

In the context of the global push for low-carbon aluminum production, molten salt heating provides a more energy-efficient alternative. Lower energy consumption in the lab can lead to energy savings and reduced emissions in large-scale operations.

Supporting Green Aluminum and Carbon Neutrality Goals

The green aluminum movement emphasizes reducing greenhouse gas emissions during production. Laboratory molten salt furnaces are instrumental in developing eco-friendly aluminum electrolysis processes, such as:

- Inert anode research for reducing CO₂ emissions

- Optimized electrolyte compositions for lower temperature electrolysis

- Recycling of spent electrolytes and minimizing waste generation

By leveraging molten salt furnace technology, researchers are contributing to carbon-neutral aluminum production, aligning with global sustainability initiatives.

Key Applications in Aluminum Electrolysis Research

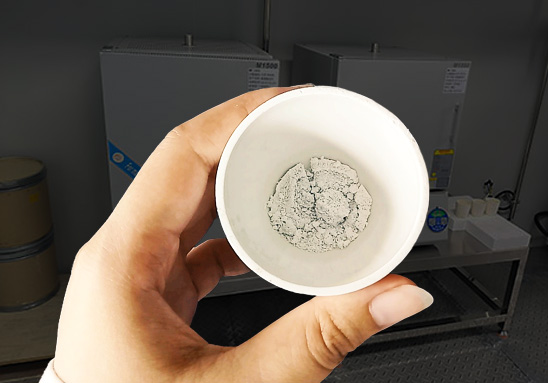

1. Precursor Material Pretreatment

Laboratory molten salt electric furnaces are used to preheat and treat aluminum precursor materials, ensuring purity and consistency before entering the electrolytic process.

2. Electrolyte Optimization Studies

The controlled environment of molten salt furnaces enables the fine-tuning of electrolyte chemistry, improving current efficiency and reducing energy loss.

3. Electrode Material Testing

Researchers can simulate the high-temperature environment of industrial electrolysis to test new anode and cathode materials, focusing on durability, electrochemical stability, and environmental performance.

Molten Salt Electroplating Furnace: Advantages in Critical Metal Extraction

Benefits of Using Molten Salt Electric Heating Furnaces

| Benefits | Impact on Aluminum Electrolysis |

| Precise temperature control | Enhances process consistency and product quality |

| High thermal efficiency | Reduces energy consumption and lowers costs |

| Stable heating environment | Improves reaction kinetics and current efficiency |

| Eco-friendly operation | Supports carbon reduction and green manufacturing |

Future Trends and Innovations

1. Integration with Smart Control Systems

Modern laboratory molten salt furnaces now feature PID intelligent temperature control, data logging, and remote monitoring capabilities. These digital upgrades make it easier to automate experiments, reduce human error, and improve reproducibility.

2. Advanced Materials and Coatings

The development of corrosion-resistant materials for molten salt containment allows for longer furnace life and broader compatibility with different electrolyte compositions.

3. Applications Beyond Aluminum Electrolysis

Besides aluminum, molten salt furnaces are being explored in battery material synthesis, nuclear molten salt reactors, and high-temperature energy storage systems.

Frequently Asked Questions (FAQs)

What temperatures can laboratory molten salt furnaces achieve?

Most laboratory molten salt electric heating furnaces operate between 300°C and 1200°C, depending on the molten salt mixture used.

How do molten salt furnaces improve aluminum electrolysis experiments?

They offer precise temperature control, uniform heating, and simulate industrial-scale conditions, allowing for accurate testing and optimization of electrolytes and electrodes.

Are molten salt furnaces environmentally friendly?

Yes. By reducing energy consumption and enabling the development of low-carbon electrolysis technologies, they contribute to greener aluminum production.

Conclusion

Laboratory molten salt electric heating furnaces are reshaping aluminum electrolysis research and development, offering energy efficiency, precise control, and environmental benefits.

As the aluminum industry transitions toward green and sustainable manufacturing, these furnaces will play an increasingly important role in achieving carbon neutrality goals.

If you’re looking for advanced laboratory molten salt electric furnaces to support your aluminum electrolysis experiments, ZYLAB offers customized solutions tailored to your research needs.

Contact us today to find the best furnace for your application!

Share this entry

You might also like