Table of Contents

Introduction

As global demand for critical metals rises in industries such as renewable energy, aerospace, and electronics, efficient and sustainable extraction technologies are becoming increasingly important.

Among these technologies, molten salt electroplating (MSE) furnaces have emerged as a promising solution for extracting and refining high-purity metals.

Compared to conventional methods, MSE furnaces offer higher efficiency, lower environmental impact, and improved metal purity, making them ideal for research laboratories and pilot-scale metal production.

Key Advantages

1. High Purity Metal Extraction

Traditional metal extraction methods often introduce impurities due to complex chemical reactions and secondary contaminants.

In contrast, MSE furnaces operate under high-temperature molten salt conditions, enabling direct electrodeposition of ultra-pure metals with minimal contamination. This is particularly crucial for rare earth elements, lithium, magnesium, and titanium, where high purity is essential for advanced applications.

Key Benefits:

- Electrochemical precision ensures controlled metal deposition

- No gas-phase contamination, leading to higher purity

- Eliminates the need for additional refining processes

2. Energy Efficiency and Cost Savings

Compared to traditional smelting or hydrometallurgical processes, molten salt electroplating consumes less energy while maintaining high extraction efficiency. The process operates at relatively lower temperatures and does not require high-pressure operations, reducing overall energy consumption and operational costs.

Key Benefits:

- Lower power consumption than conventional smelting

- Reduced operational costs due to simplified processing

- Minimal energy waste, making it a sustainable solution

3. Environmentally Friendly Process

Sustainability is a major concern in metal extraction. Traditional methods, such as chemical leaching and ore roasting, generate hazardous wastewater, CO₂ emissions, and toxic byproducts.

MSE furnaces minimize environmental impact by operating in a closed-loop system, producing fewer emissions and reducing the need for harmful reagents.

Key Benefits:

- No hazardous chemical waste

- Lower CO₂ emissions compared to conventional methods

- Sustainable solution for green metallurgy

4. Versatility for Various Critical Metals

Molten salt electroplating furnaces can be adapted for different critical metal extraction processes, making them highly versatile. From rare earth elements (REEs) to refractory metals such as tungsten, niobium, and tantalum, these furnaces provide an optimized environment for controlled deposition.

Key Benefits:

- Customizable furnace configurations for different metals

- Ability to handle high-melting-point metals

- Compatible with multiple electrolyte compositions

5. Ideal for Research and Pilot-Scale Production

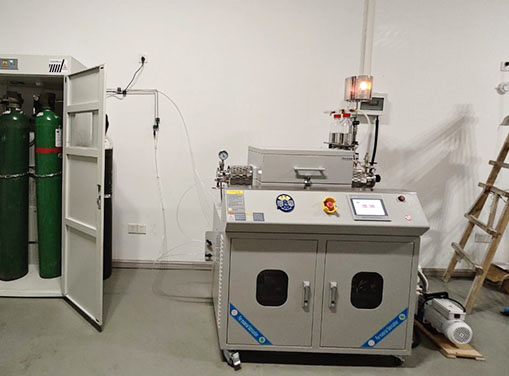

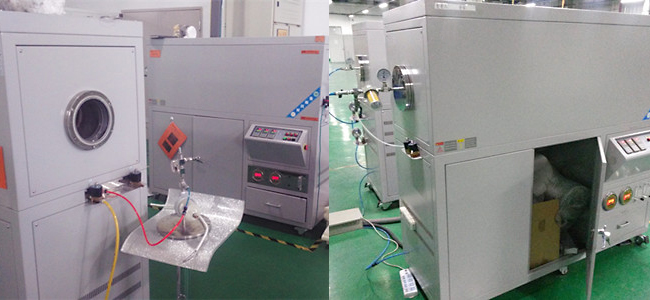

While large-scale industrial production of critical metals often requires complex, high-capacity equipment, ZYLAB’s molten salt electroplating furnaces are designed for research laboratories and pilot-scale facilities.

They provide a controlled environment for studying metal extraction processes, optimizing electroplating conditions, and testing new materials before scaling up to full industrial production.

Key Applications:

- University and research institute laboratories

- Pilot-scale metal refining for process development

- Battery materials research (e.g., lithium and cobalt extraction)

- Rare earth element purification studies

By focusing on laboratory and pilot-scale applications, ZYLAB furnaces help researchers bridge the gap between fundamental studies and industrial implementation.

Why Choose ZYLAB’s Molten Salt Electroplating Furnace?

ZYLAB specializes in high-performance molten salt electroplating furnace solutions, designed for precision, efficiency, and sustainability. Our furnaces feature:

- Advanced temperature control systems for precise metal deposition

- Customizable atmosphere control to prevent oxidation

- High-quality refractory materials for durability and longevity

- User-friendly automation options for seamless operation

Conclusion

The adoption of molten salt electroplating furnaces marks a significant advancement in critical metal extraction and purification.

With higher efficiency, lower environmental impact, and cost-effective operation, MSE technology is transforming laboratory and pilot-scale research.

ZYLAB’s molten salt electroplating furnaces provide an excellent solution for researchers and small-scale production facilities.

Looking for an advanced furnace for critical metal extraction? Contact ZYLAB today to explore our customizable solutions!