Table of Contents

Introduction

When it comes to high-temperature laboratory and industrial heating equipment, Muffle Furnaces and Tube Furnaces are two of the most commonly used options. Both offer precise temperature control and excellent thermal stability, but their designs and applications differ significantly.

This article provides a detailed comparison to help you determine which furnace best suits your specific needs.

Key Differences Between Muffle Furnaces and Tube Furnaces

The table below highlights the primary distinctions between these two types of furnaces:

| Feature | Muffle Furnace | Tube Furnace |

| Design | Box-shaped chamber with insulation | Cylindrical tube with heating elements |

| Heating Method | Surrounds the sample with uniform heat | Heats the sample inside a tube |

| Temperature Range | RT – 1700°C | RT – 1700°C |

| Atmosphere Control | Limited (mostly air or inert gas) | Supports vacuum, gas flow, and controlled environments |

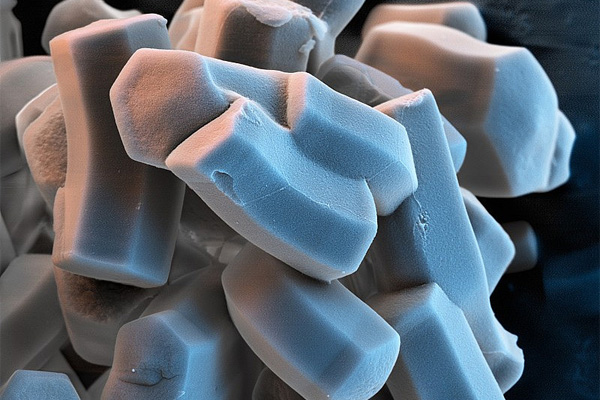

| Sample Type | Bulk materials, crucibles, and plates | Powders, rods, and materials requiring gas interaction |

| Uniformity | Excellent for large samples | Better for small samples in controlled environments |

| Application Fields | Material testing, heat treatment, sintering | Synthesis, chemical reactions, and controlled gas atmospheres |

Choosing the Right Furnace for Your Needs

1. Application Requirements

Choose a Muffle Furnace if:

- You need uniform heating for bulk materials, ceramics, or metal samples.

- Your process involves ashing, annealing, or heat treatment in an air environment.

- You require a chamber-style furnace for laboratory-scale or industrial applications.

Click here to view the comprehensive guide to muffle furnaces!

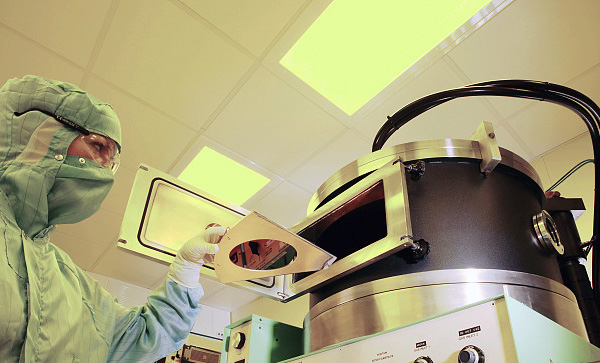

Choose a Tube Furnace if:

- You need precise atmosphere control, such as inert gas or vacuum conditions.

- Your samples require a uniform flow of gas, such as in chemical vapor deposition (CVD) or gas-solid reactions.

- You work with small samples, powders, or elongated materials.

Click here to view the comprehensive guide to tube furnaces!

2. Temperature and Atmosphere Considerations

Muffle furnaces offer stable high-temperature conditions but are limited in atmosphere control.

Tube furnaces provide excellent gas flow capabilities, making them ideal for oxidation-sensitive or reactive materials.

3. Sample Size and Uniformity

Muffle furnaces are better suited for larger samples and bulk processing.

Tube furnaces provide better uniform heating for smaller samples in controlled conditions.

Conclusion

Both muffle furnaces and tube furnaces serve essential roles in high-temperature applications, but choosing the right one depends on your specific needs.

If you require a chamber-style furnace for bulk materials, a Muffle Furnace is the best choice. However, if you need controlled atmospheres and precise gas flow for your experiments, a Tube Furnace is more suitable.

ZYLAB offers a range of high-performance Muffle Furnaces and Tube Furnaces tailored to various industrial and research applications. Contact us today to find the ideal furnace for your laboratory or production needs!