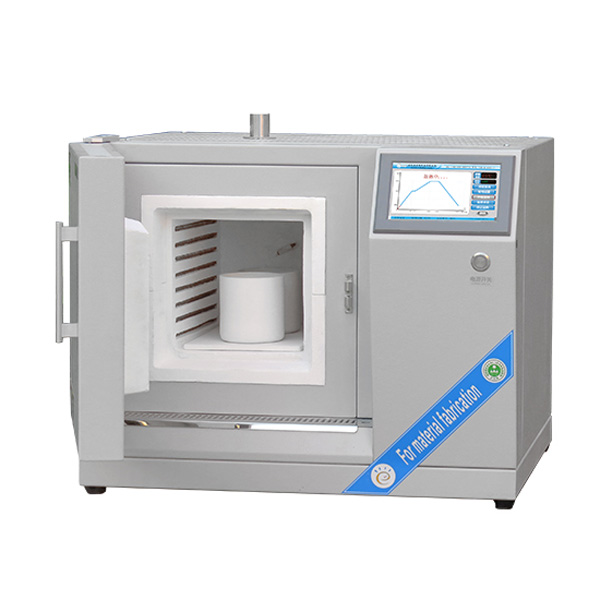

Lab Muffle Furnace for Biochar R&D

Introduction

This Muffle Furnace for Biochar R&D is specially designed to meet customer needs, offering high cost-performance. With a simplified classic design and a sintering chamber made of lightweight alumina fiber, it features touch screen controls for seamless human-machine interaction, making operation exceptionally convenient.

Features and Benefits

- Moderate Furnace Volume: Suitable for a variety of material heat treatment processes.

- Advanced Insulation Materials: Made with refractory and insulating materials that minimize heat loss and effectively reduce power consumption.

- Modular Structure: Durable and easy to maintain.

- Exhaust Chimney: The furnace top is equipped with a chimney to efficiently remove volatiles produced during the sintering process.

- Touch Screen Operation: Intuitive display of temperature curves.

Technical Parameters

| Model | M1200 | |

| Power | AC220V 3.5KW | |

| Max.temp | 1200℃(<1hour) | |

| Working temp | 1100℃(Continuous) | |

| Heating rate | ≤20℃/min | |

| Chamber size | W200*H120*D300mm(other optional sizes: 200*200*300mm, 300*300*300mm,400*400*400mm, 400*400*500mm) | |

| Outer dimensions | W420*H530*D570mm | |

| Control system |  |

1. PID automatic control and auto-tune function. 2. 30 programmable segments for precise control. 3. Built in protection for over-heated and broken thermal couple, and leakage. 4. Centralized control 7” color LCD touch screen man-machine English graphics interface, clear heating process, more intuitive and convenient operation. 5. Can store sintering programs to avoid the trouble caused by repeated settings of different experimental processes. |

| Accuracy | +/- 1℃ | |

| Heating Elements |  |

Top quality resistance wire(Mo-doped Fe-Cr-Al alloy) |

| Net weight | Approximately 40KG | |

| Service Support | 1-year warranty with lifetime support (warranty excludes consumable parts). | |

Optional

- Special corrosion-resistant furnace chamber

- Observation window

- Atmosphere protection box: An accessory for the furnace designed to create and maintain a specific atmospheric environment to protect materials from oxidation, contamination, or adverse reactions with air (customizable dimensions).

Applications of Muffle Furnace for Biochar R&D

- Biochar Production (Pyrolysis): Muffle furnaces are used for controlled pyrolysis of biomass, optimizing temperature and oxygen-limited conditions to produce high-quality biochar.

- Biochar Characterization and Testing: Analyzing biochar’s chemical composition, surface area, and porosity to evaluate its potential for soil enhancement and water filtration.

- Environmental Remediation: Testing biochar’s ability to adsorb heavy metals (e.g., lead, arsenic) for water purification applications.

- Biochar Activation and Modification: Using muffle furnaces to activate or modify biochar to improve its adsorption capacity and catalytic properties.

- Soil Improvement Research: Producing biochar to test its effects on soil pH, nutrient retention, water holding capacity, and microbial activity.

- Biochar Composite Development: Combining biochar with polymers or other materials to create new composite materials for various applications.

- Waste-to-Energy Conversion: Converting organic waste into biochar and generating bio-oil and syngas for energy production.

- Durability and Stability Testing: Studying the thermal stability and oxidative resistance of biochar under high temperatures for long-term applications.

- Animal Feed Additive Research: Testing biochar as a feed supplement to improve digestion and reduce methane emissions in livestock.

- Pilot-Scale Production: Muffle furnaces are suitable for small-scale pyrolysis experiments, simulating larger-scale biochar production processes.

Muffle furnaces provide precise temperature control, making them essential for optimizing biochar properties and expanding its applications.

For More Solutions on Biochar R&D Field

Please visit our website [Biochar R&D Collection]

Explore More on Our Blog

Please visit our Blog