Introduction

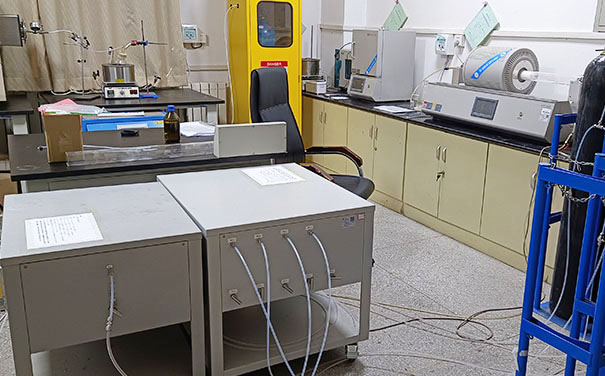

Box furnaces are essential high-temperature heating equipment used in laboratories, research facilities, and industrial settings. They provide a controlled environment for applications such as heat treatment, sintering, and material testing. Their box-like chamber design allows for uniform temperature distribution, making them ideal for various thermal processing tasks.

Key Applications of Box Furnaces

- Heat Treatment – Used for annealing, tempering, and hardening of metals and alloys.

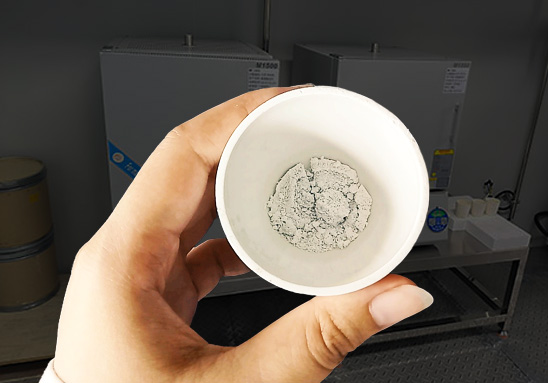

- Sintering and Ceramics Processing – Suitable for sintering powder metallurgy components and firing ceramics.

- Glass and Material Research – Employed in melting, crystallization, and phase transformation studies.

- Ashing and Combustion Testing – Used in material analysis, including loss-on-ignition (LOI) tests.

- Electronic Component Processing – Supports high-temperature curing and stress testing of semiconductor materials.

Factors to Consider When Choosing a Box Furnace

1. Temperature Range

Selecting the right temperature range is critical for achieving the desired process outcomes:

- 800-1200°C – Suitable for basic ashing, heat treatment, and sample drying.

- 1200-1500°C – Used for sintering, ceramic processing, and advanced metallurgical studies.

- 1500-1700°C – Ideal for high-purity material research, advanced sintering, and specialized applications.

2. Chamber Size and Capacity

The furnace chamber size determines the sample volume that can be processed. Laboratory-scale box furnaces typically range from 1L to 80L, depending on the application requirements.

Selecting the right capacity ensures efficient heating and uniform sample treatment.

3. Atmosphere Control

Some processes require controlled atmospheres, such as inert gases (argon, nitrogen) or vacuum conditions, to prevent oxidation and achieve specific material properties.

Choosing a furnace with gas flow control or vacuum capabilities can enhance process precision and repeatability.

Advantages of Box Furnaces

- Uniform temperature distribution for consistent processing results.

- High efficiency and energy-saving designs with advanced insulation.

- Versatile applications across multiple industries.

- Optional atmosphere control for oxidation-sensitive materials.

Choosing the Right Box Furnace

To select the most suitable box furnace for your needs, consider:

- Process requirements – Define the temperature range and atmosphere conditions.

- Sample volume – Choose an appropriate chamber size for your workload.

- Heating efficiency – Look for models with advanced insulation and temperature uniformity.

Conclusion

Box furnaces are highly versatile and widely used in scientific research and industrial applications. Whether you need a furnace for heat treatment, sintering, or material analysis, choosing the right specifications is essential for achieving optimal results.

ZYLAB offers high-quality box furnaces designed to meet various thermal processing needs. Contact us today to find the ideal solution for your application!

Share this entry

You might also like