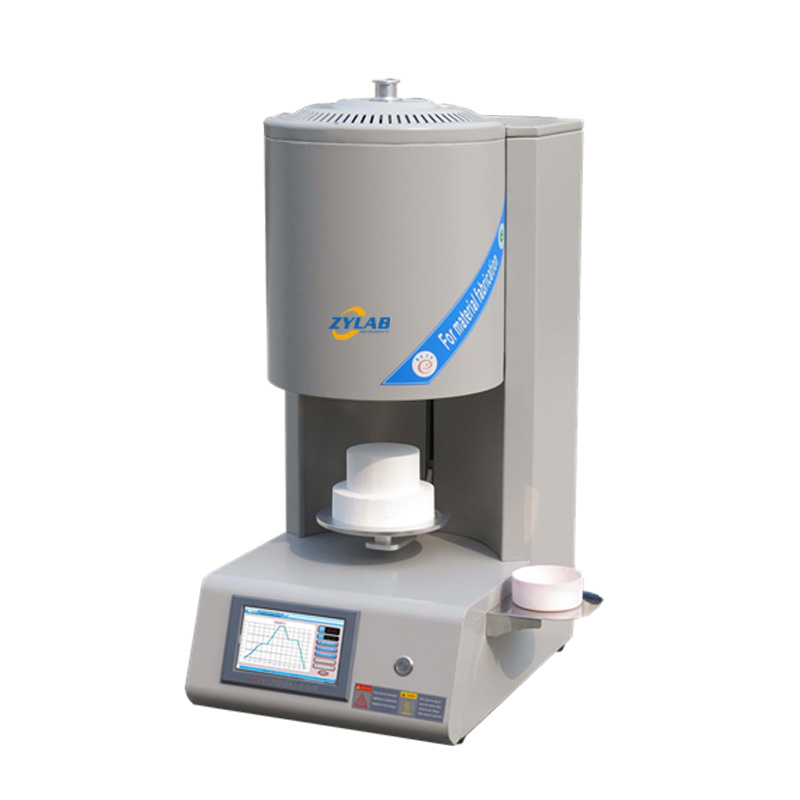

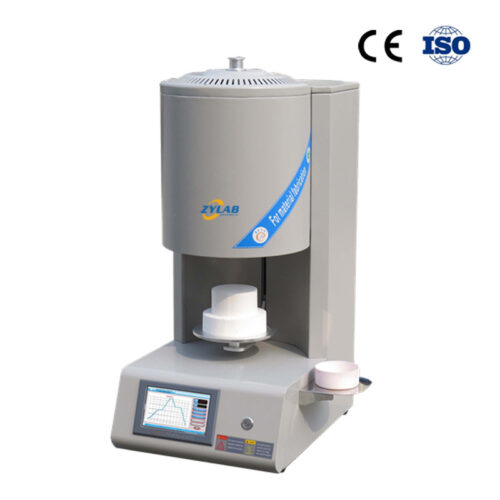

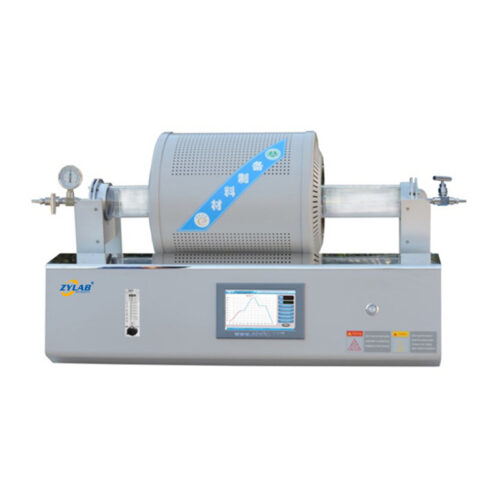

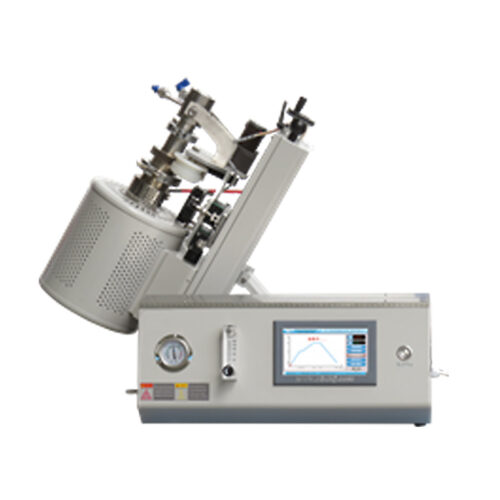

High-Temperature Bottom Loading Sintering Furnace – Precision Sintering with Convenient Material Handling

Introduction

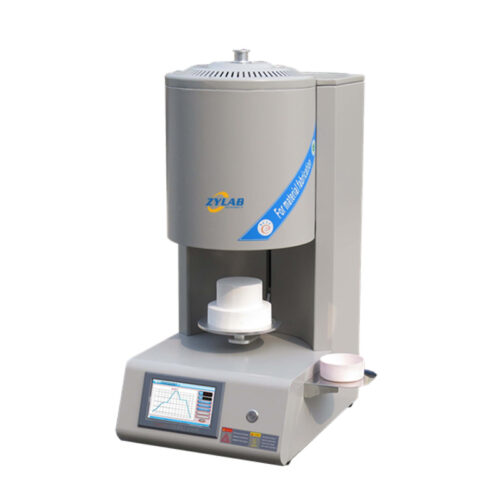

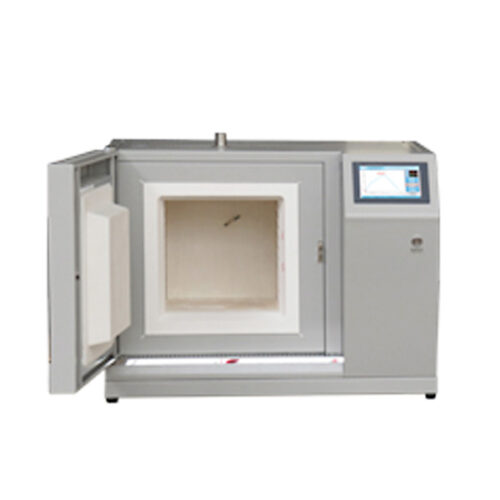

This series bottom loading sintering furnaces come with electric lift platform design greatly simplifies the loading process. The heating elements are distributed in a circular arrangement, enhancing the uniformity of the temperature field. It is suitable for the heat treatment of metals, ceramics, glass, and other materials. The lift structure design also allows for high-temperature loading and unloading operations.

Main Features of Bottom Loading Sintering Furnace

- Silent Lift Platform Design – Ensures stable lifting to prevent material tilting, making loading simple and quick.

- Lift Structure for High-Temperature Loading/Unloading – Allows safe handling of materials at high temperatures.

- Advanced Automation Control – Guarantees system stability during operation and control.

- Touchscreen Operation – Intuitive display of temperature curves, simplifying the operation process.

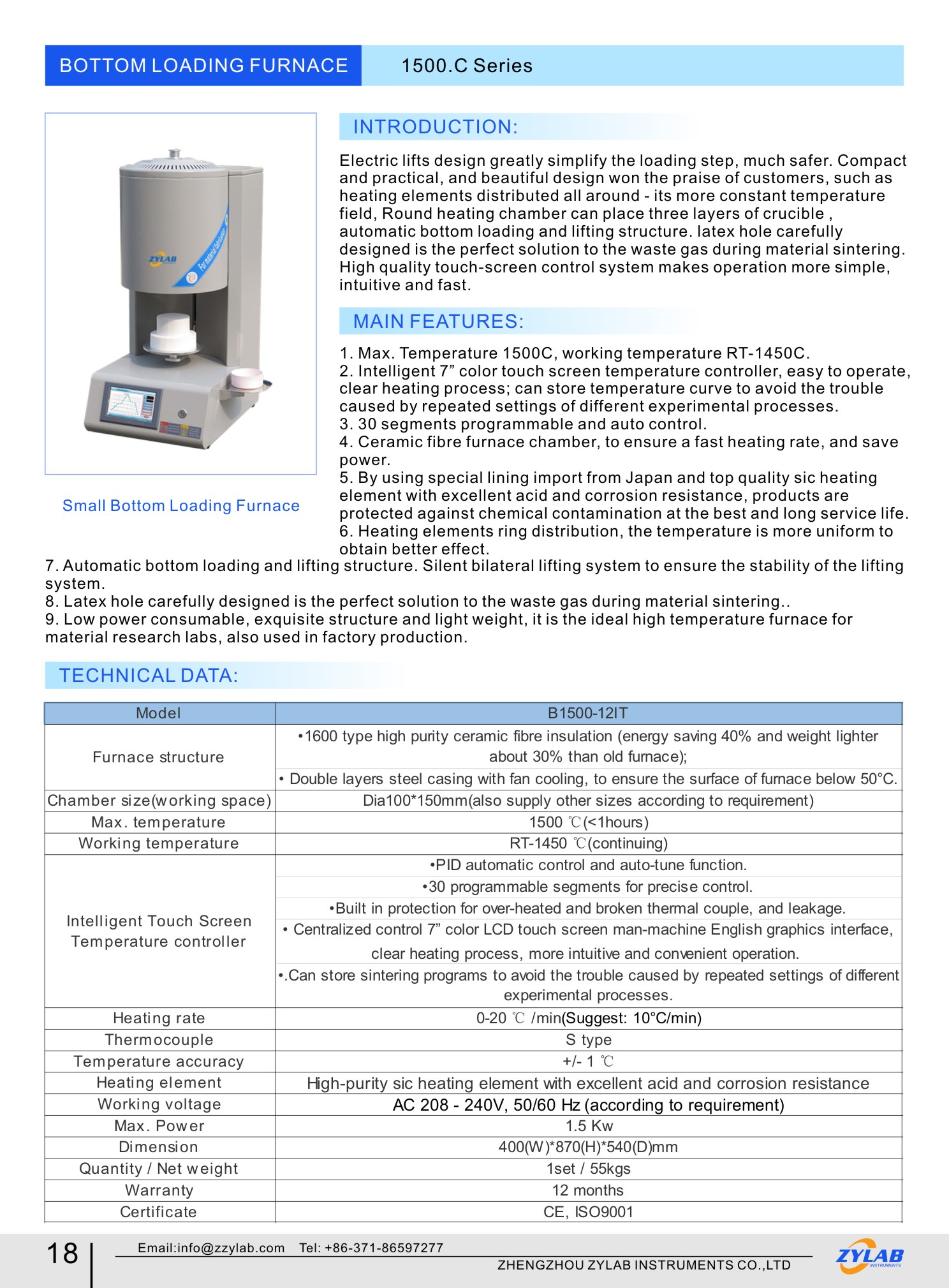

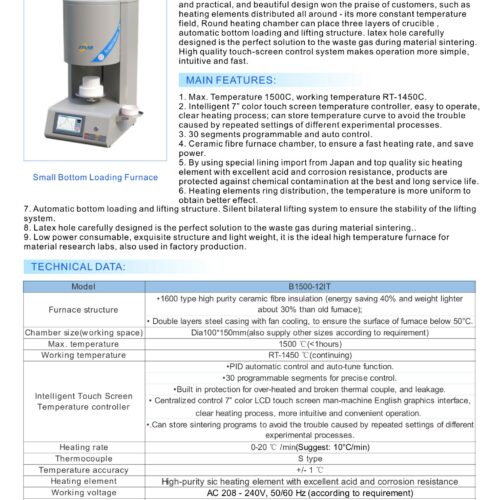

Technical Parameters

| Model | B1200-10 | B1500-12 | B1700-12 |

| Power Supply | AC220V 1.4KW | AC220V 1.5KW | AC220V 1.8KW |

| Max Temperature | 1200°C (<1hr) | 1500°C (<1hr) | 1700°C (<1hr) |

| Continuous Temp | 1150°C (cont.) | 1450°C (cont.) | 1650°C (cont.) |

| Heating Rate | ≤20°C/min | ≤20°C/min | ≤20°C/min |

| Chamber Size | Φ90*70mm | Φ100*120mm | Φ100*120mm |

| Control System | 1. Embedded system with bilingual (Chinese/English) graphical interface, 7-inch true-color touchscreen, intelligent human-machine dialogue, real-time heating power display, and nonlinear temperature correction.

2. Can store up to 15 temperature curves, each with 30 “temperature-time” segments, eliminating repetitive setup for different experimental processes. 3. Features over-temperature alarm, thermocouple disconnection alert, and leakage protection.

|

||

| Temperature Accuracy | +/- 1°C | +/- 1°C | +/- 1°C |

| Heating Elements | Molybdenum-doped iron-chromium-aluminum alloy heating wire

|

Special high-density and high-purity silicon carbide rod

|

High-purity silicon-molybdenum rods

|

| Net Weight | 30KG | 55KG | 75KG |

| Equipment Usage Precautions | 1. When sintering samples, the furnace platform must be placed on the tray.

Do not lower the entire furnace platform when the temperature is high (please contact the manufacturer directly for special cases). |

||

| Service Support | 1-year warranty, lifetime support (warranty does not cover consumable parts like thermocouples, heating elements, etc.). | ||

Which kinds of industry can use this Bottom Loading Sintering Furnace?

College & Universities, New Material Research, Chemistry, Medicine, Building Materials, Coal Mining, Metallurgy, Electronics, Ceramic, etc.

Applications

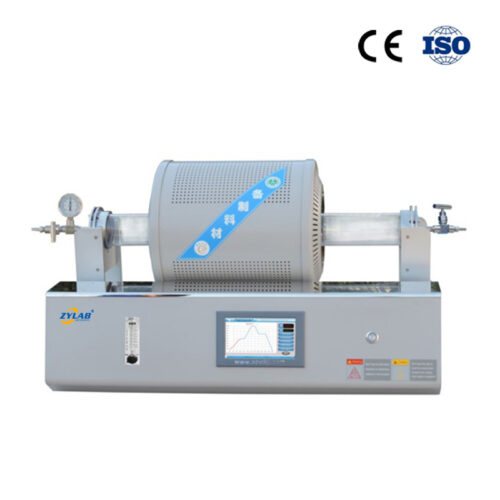

Bottom loading furnaces are widely used in various industries for their ease of loading and unloading from the bottom. Here are some key applications:

- Material Science: For sintering, annealing, and other thermal treatments of materials.

- Metallurgy: Used in metal processing and heat treatment.

- Chemical Engineering: For reactions, calcination, and other high-temperature processes.

- Ceramics: Suitable for firing and sintering ceramic materials.

- Laboratory Research: Applied in scientific studies and experiments requiring controlled high-temperature environments.

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]