Table of Contents

In material science research, precise temperature and atmospheric control are crucial for developing materials with enhanced properties.

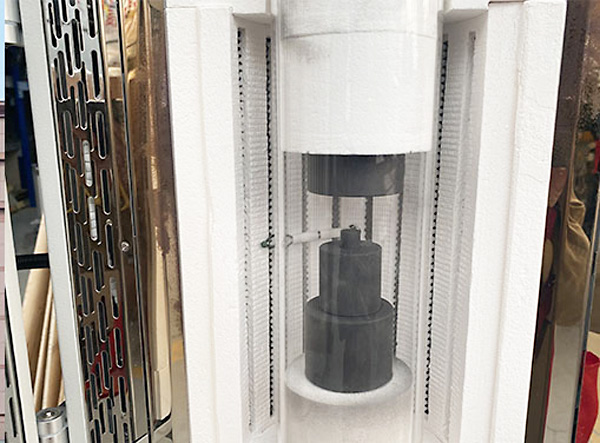

A university’s materials science department recently integrated a 1700℃ vacuum atmosphere furnace into their research facilities, significantly advancing new ceramic material development and metal heat treatment studies.

Enhancing New Ceramic Material Development

Ceramic materials are widely used in electronics, aerospace, and biomedical applications due to their exceptional thermal and mechanical properties. However, achieving desired properties requires precise control of temperature and atmosphere during sintering and processing.

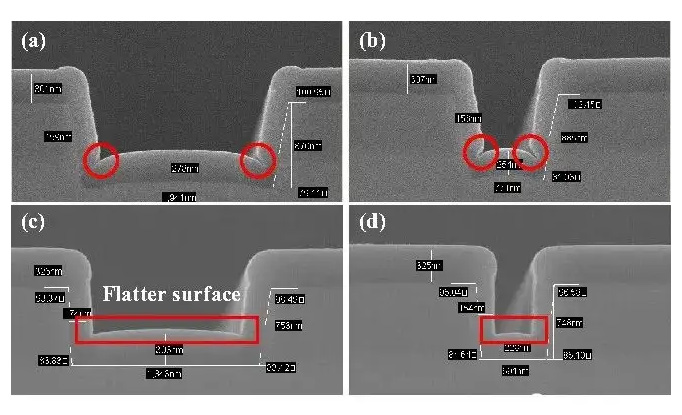

- Optimized Sintering Conditions – The vacuum atmosphere furnace provides a stable, high-temperature environment that allows researchers to fine-tune sintering parameters, ensuring uniform densification and enhanced mechanical strength.

- Improved Electrical Conductivity – Through controlled oxidation and reduction reactions, researchers successfully synthesized ceramic materials with superior electrical conductivity, expanding their applications in advanced electronic components.

- Minimized Defects – By eliminating unwanted gas impurities in the chamber, the furnace ensures a high-purity processing environment, reducing defects such as porosity and grain boundary contamination.

Using these advancements, researchers have developed ceramic materials with improved strength, durability, and conductivity, paving the way for their integration into next-generation electronic devices.

Advancing Metal Heat Treatment Research

Heat treatment plays a critical role in tailoring metal properties such as hardness, ductility, and corrosion resistance. Traditional heat treatment methods often suffer from oxidation and contamination, leading to inconsistent results. The vacuum atmosphere furnace addresses these challenges by providing a controlled environment for metal processing.

- Microstructure Optimization – Precise temperature control allows researchers to manipulate grain structures and phase transformations, enhancing the mechanical properties of metals used in high-performance applications.

- Oxidation Prevention – By operating in a vacuum or controlled gas atmosphere, the furnace prevents oxidation and unwanted reactions, ensuring high-purity metal surfaces ideal for aerospace and medical applications.

- Enhanced Strength & Toughness – Researchers have successfully utilized the furnace to optimize heat treatment cycles, improving metal strength and toughness for industrial and scientific applications.

Through these processes, the furnace has helped researchers develop stronger, more durable metal alloys, improving their performance in demanding environments such as automotive engineering, aerospace, and high-tech manufacturing.

Why Choose ZYLAB Vacuum Atmosphere Furnace?

ZYLAB’s vacuum atmosphere furnace stands out due to its advanced engineering, user-friendly control system, and precision processing capabilities. Key benefits include:

- Dual-Layer Water-Cooled Structure – Effectively reduces exterior surface temperatures, ensuring safe operation.

- Smart Process Control – Features non-linear temperature correction for accurate thermal profiling.

- Data Logging & Remote Monitoring – Allows for real-time monitoring, data export, and experiment reporting, ensuring seamless research documentation.

- Customizable Chamber Size & Atmosphere Options – Tailored to meet specific research and industrial needs.

Click here to view ZYLAB vacuum furnaces!

Conclusion

The 1700℃ vacuum atmosphere furnace has proven to be an essential tool in new ceramic material development and metal heat treatment research. By providing precise temperature control and an oxidation-free environment, it enables scientists to achieve breakthrough advancements in material properties.

As industries continue to demand high-performance ceramics and optimized metal alloys, such furnaces will remain a key component in shaping the future of material science.

For more information or technical support, feel free to contact ZYLAB.

Share this entry

You might also like