Tablet Press Annular Ring Molds

Details

Annular ring molds are specialized molds designed for pressing ring-shaped samples with a central hole. They are widely used in material science, powder metallurgy, catalyst research, and spectroscopic analysis, such as X-ray fluorescence (XRF) and infrared spectroscopy (IR).

These molds are typically made of high-strength alloy steel to ensure durability and precision. Their key advantage is the ability to control both the inner and outer diameters of the sample, resulting in excellent dimensional stability and uniform density distribution.

Annular Ring Molds are commonly used with hydraulic pellet presses or isostatic pressing equipment to apply uniform pressure, producing high-quality ring-shaped samples suitable for laboratory research and small-scale production.

Customization options are available to meet specific material and size requirements, providing researchers with a precise and efficient solution for powder compaction.

To grind the required materials into powder with the correct particle size ( from millimeters to micrometers), we recommend using our planetary ball mill and accessories or agate mortar and pestle set.

Applications

- Material Science Research

- Used to form ring-shaped samples for testing material properties such as density, hardness, and thermal conductivity.

- Powder Metallurgy

- Essential for pressing metal and ceramic powders into precise annular shapes, aiding in sintering and mechanical property evaluation.

- Catalyst Development

- Helps in preparing catalyst rings for industrial and laboratory-scale catalytic reaction testing.

- Spectroscopic Analysis (XRF & IR)

- Commonly used for making standardized samples for X-ray fluorescence (XRF) and infrared spectroscopy (IR) to ensure accurate chemical composition analysis.

- Battery and Energy Storage Research

- Applied in lithium-ion battery studies to create electrode materials in annular shapes for performance evaluation.

- Small-Scale Production

- Used for precision manufacturing of custom-designed components in industries requiring high-quality ring structures.

Parameter

| ZYLAB Annular Ring Molds | |||||

| Sample Size | φ7-3mm | φ10-5mm | φ20-10mm | φ30-10mm | φ50-20mm |

| Material | Alloy Tool Steel Cr12MoV | ||||

| Indenter Hardness | HRC60-HRC62 | ||||

| Cavity Depth | 40mm | 45mm | |||

| Boundary Dimension | Φ53×120mm | Φ72×100mm | Φ88×120mm | ||

| Weight | 1.4Kg | 3.5Kg | 5Kg | ||

Specifications

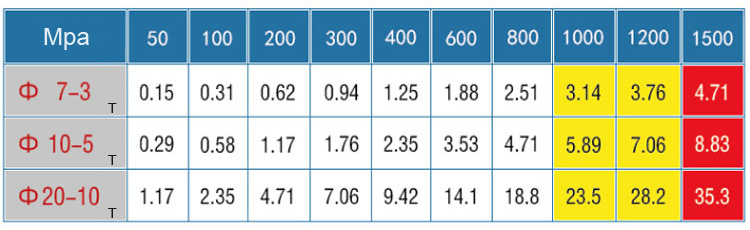

ZYLAB’s standard sizes for annular ring molds are φ7-3mm, φ10-5mm, φ20-10mm, φ30-10mm, and φ50-20mm.

Custom sizes are available upon request, with delivery times ranging from 3 to 20 days.

If you need more detailed information, please contact us immediately. We offer free quotes on all products!

Pressure Matching

Note: Molds are generally used within the pressure range of 100-800 MPa and can reach up to 1500 MPa.

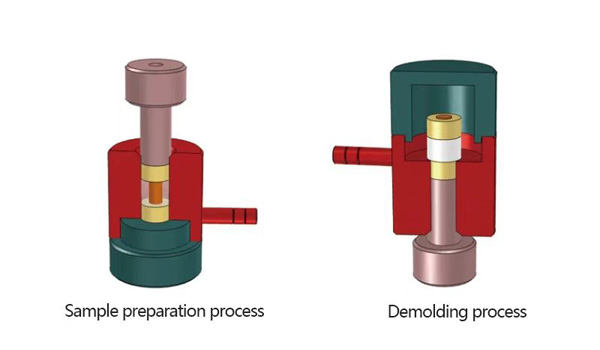

Operational Diagram of Dry Pellet Pressing Mold

Usage and Maintenance

- Before each use, clean the surface of the mold with lint-free paper to remove any anti-rust oil, as it may affect the accuracy of sample test results.

- Place the mold at the center of the tablet press, ensuring the applied pressure does not exceed the mold’s maximum pressure capacity.

- After use, promptly clean any remaining sample from the mold to prevent corrosion.

- If residual samples on the mold surface cannot be removed, avoid using chemical reagents for cleaning or soaking.

- For long-term storage, apply anti-rust oil to the mold and store it in a dry environment.

For More Options on Mold

- Cylindrical Pill Press Mold Kit

- Cylindrical Split Mold

- Square Dry Pellet Pressing Mold

- Square Split Pressing Die Set