Tube furnaces are indispensable tools in both scientific research and industrial applications. Known for their precise temperature control and uniform heat distribution, these furnaces are widely used in processes such as material synthesis, sintering, annealing, and calcination.

The heating elements are the core of a tube furnace. Made from high-performance materials such as Kanthal, silicon carbide, or molybdenum disilicide, these elements generate heat when an electric current passes through them.

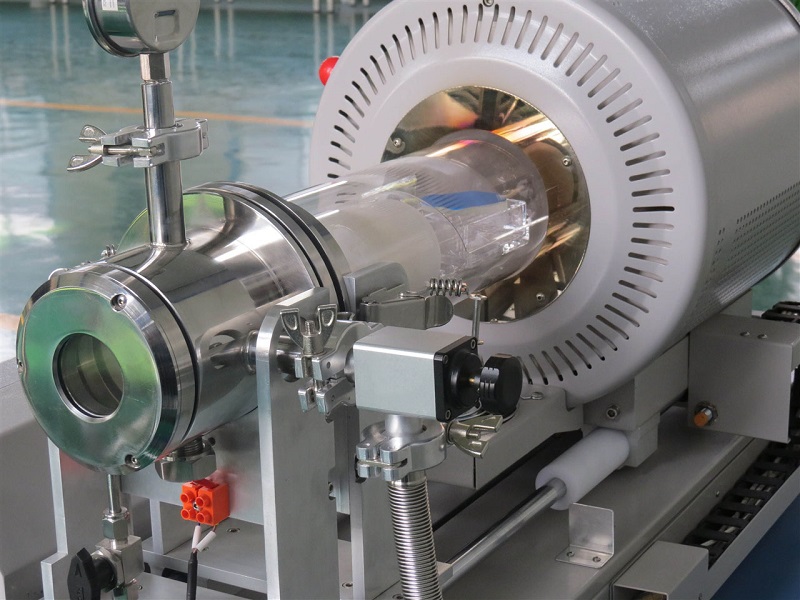

The heating elements surround the cylindrical furnace tube, which is typically made of materials like quartz, alumina, or stainless steel. The tube acts as the chamber where materials are placed for heating.

A precise temperature control system, often managed by thermocouples and a digital controller, maintains the desired temperature. This ensures consistent heating and avoids temperature fluctuations.

High-quality insulation minimizes heat loss and ensures energy efficiency.

Before starting, the sample is placed inside the furnace tube. If a controlled atmosphere is required, the tube is sealed, and the desired gas is introduced or a vacuum is applied.

When the furnace is powered on, the heating elements generate heat, which is evenly distributed around the furnace tube. The advanced temperature control system ensures the temperature rises at a specified rate and maintains the desired setpoint.

The material inside the tube undergoes the intended thermal process, such as sintering, annealing, or calcination. The cylindrical design ensures uniform heating, critical for high-quality results.

After the process, the furnace is gradually cooled down to prevent thermal shock.

Once cooled, the sample is removed for analysis or further processing.

ZYLAB is a leading supplier of scientific instruments, offering tube furnaces that combine cutting-edge technology with robust design. Here’s what sets ZYLAB apart:

In conclusion, a tube furnace is a highly efficient and versatile tool for controlled thermal processing.

ZYLAB’s tube furnaces, with their superior materials and customizable features, provide the reliability and precision needed for a wide range of applications.

For more information or technical support, feel free to contact ZYLAB.

Notifications

Welcome to ZYLAB.

Ask us anyting :)