Table of Contents

Concept and Application

Hydrogen furnace steel refers to high-performance steel produced or heat-treated in a hydrogen environment, celebrated for its exceptional purity and resistance to hydrogen embrittlement.

With the rising demand for advanced materials in hydrogen energy, aerospace, and nuclear industries, the importance of high-performance hydrogen furnace steel has grown significantly.

Laboratory research and development play a pivotal role in advancing this field, highlighting the need for specialized high-temperature furnaces capable of meeting stringent experimental requirements.

The Critical Role of High-Temperature Furnaces in Hydrogen Furnace Steel Development

High-temperature furnaces are at the heart of hydrogen furnace steel research, addressing the unique challenges posed by this process. Key requirements include:

Precise Temperature Control: The ability to achieve and maintain high temperatures, often exceeding 1200°C, with exceptional uniformity.

Hydrogen Compatibility: Ensuring safe and efficient operation with high-purity hydrogen to prevent contamination and oxidation.

Sealing Performance: Maintaining a highly sealed environment to ensure consistent results and operational safety.

Flexibility: Supporting small-batch experiments and varying heat treatment conditions to facilitate comprehensive research.

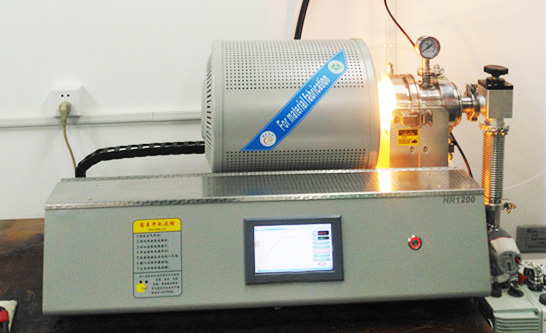

ZYLAB’s hydrogen reduction furnaces: Excellence in Design and Performance

ZYLAB’s hydrogen reduction furnaces are specifically designed to address the challenges of hydrogen furnace steel research. Here are the standout features:

Advanced Design

Superior Sealing: Utilizing advanced vacuum sealing technology, the furnaces maintain stable hydrogen environments for extended durations, ensuring process integrity.

Corrosion-Resistant Materials: Constructed with high-performance alloys resistant to hydrogen-induced corrosion, extending equipment lifespan under challenging conditions.

Precise Temperature Regulation

Multi-Zone Heating: Ensures uniform temperature distribution across the heating chamber, critical for consistent material treatment.

Smart Control Interfaces: Features programmable temperature profiles to facilitate complex heat treatment cycles with ease.

Flexible Atmosphere Control

Versatile Gas Compatibility: Supports pure hydrogen, nitrogen, argon, and other gases to meet diverse experimental needs.

Integrated Safety Systems: Includes real-time monitoring, leak detection, and emergency exhaust mechanisms to ensure safe operations.

Enhanced Efficiency

Modular Construction: Simplifies maintenance and component replacement, reducing downtime and improving operational efficiency.

Energy Optimization: High-performance insulation minimizes energy consumption, lowering operational costs and environmental impact.

Application Cases

ZYLAB’s hydrogen reduction furnaces have been instrumental in advancing hydrogen furnace steel research across multiple industries:

Aerospace Development: Enabling the production of high-performance steel for critical aerospace components.

Nuclear Materials: Facilitating the preparation of materials that withstand hydrogen-rich and high-temperature environments.

Comprehensive Support and Customization

ZYLAB offers unparalleled support and customization options to ensure optimal performance for every application:

Tailored Solutions: From specific size requirements to unique operational features, ZYLAB’s furnaces can be customized to meet any experimental need.

Dedicated Technical Assistance: Comprehensive after-sales services, including installation, training, and ongoing maintenance, provide peace of mind to users.

Global Reach: With a robust international support network, ZYLAB ensures prompt responses to customer needs worldwide.

Conclusion

ZYLAB’s hydrogen reduction furnaces empower researchers and industries to unlock the full potential of hydrogen furnace steel. With advanced design, precise control, and unparalleled flexibility, our furnaces provide the ideal solution for cutting-edge research and development.

Contact ZYLAB today to discover how our high-temperature furnaces can transform your research capabilities and drive innovation in hydrogen furnace steel production.

Share this entry

You might also like