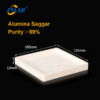

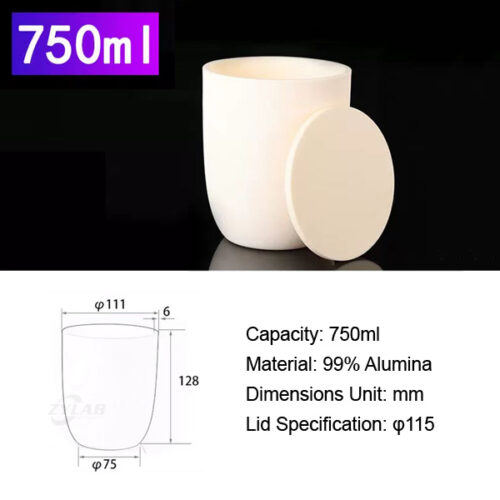

Alumina Conical Muffle Furnace Crucible with Lid

Product Details:

Conical Muffle Furnace Crucible with Lid is a high-purity laboratory tool designed for high-temperature applications requiring precision and durability.

Made from 99% alumina, this crucible offers exceptional thermal resistance, chemical stability, and excellent performance in extreme heat conditions.

The conical shape facilitates efficient heat flow and easy handling, while the matching lid minimizes contamination, prevents material loss, and helps maintain a controlled atmosphere during heating.

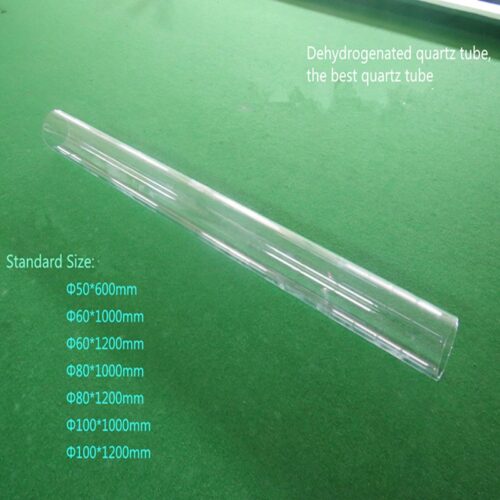

This crucible is specifically engineered for use in muffle furnaces and crucible furnaces, making it suitable for processes such as sintering, calcination, melting, and thermal analysis. Durable, reliable, and precise, it is widely used in scientific research, industrial production, and material testing.

Alumina Purity: >99%

Maximum temperature resistance: 1750°C

Continuous operating temperature: ≤1600°C

The lid can be purchased separately.

We offer customized services according to your requirements!

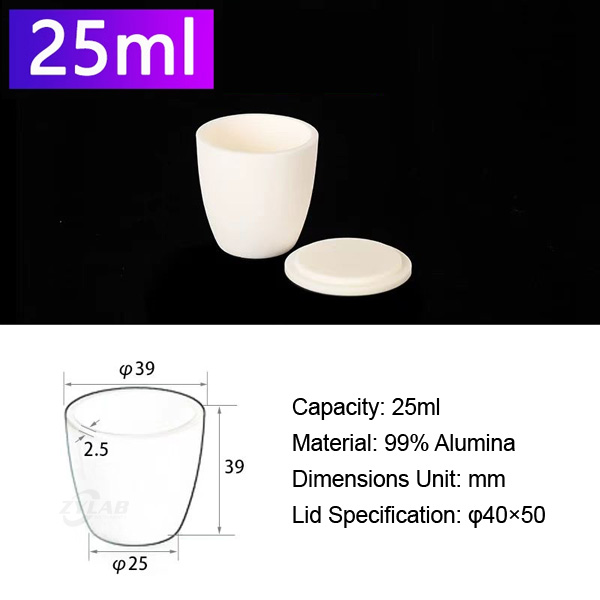

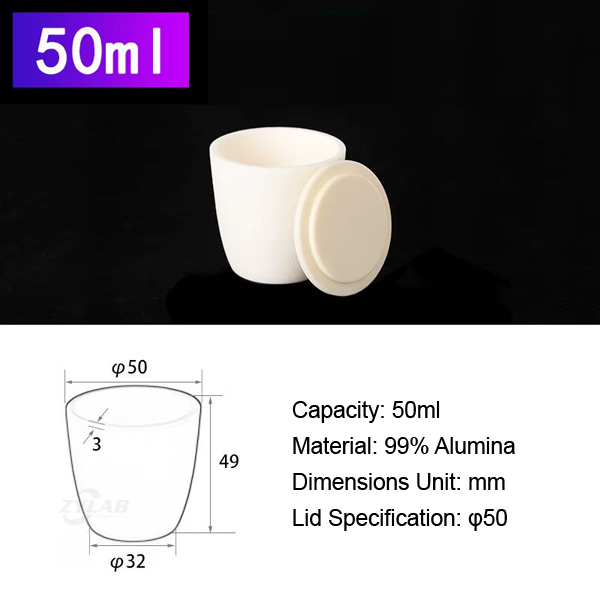

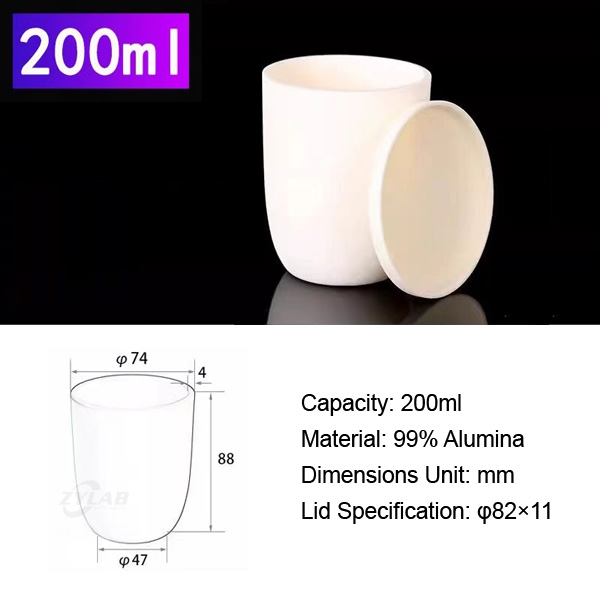

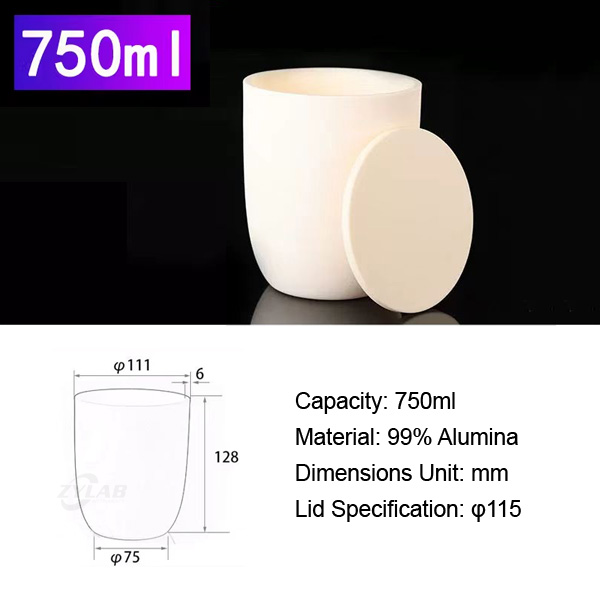

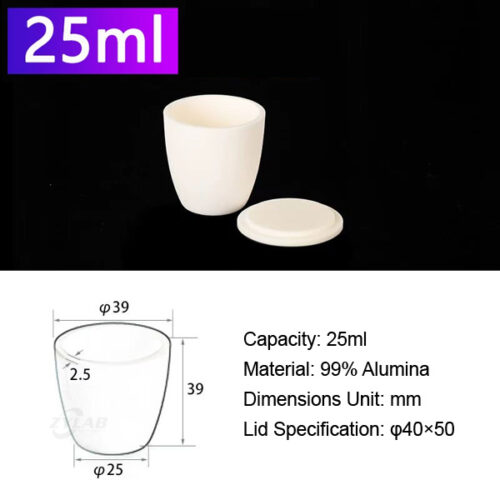

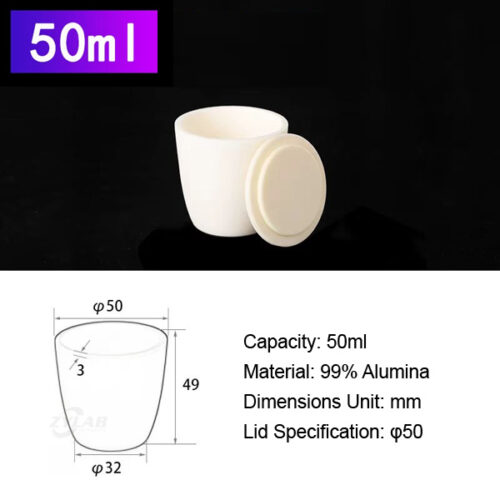

Standard Specifications for Conical Muffle Furnace Crucible with Lid:

| Conical Muffle Furnace Crucible with Lid | ||||||

| 3ml | 4ml | 5ml | 10ml | 15ml | 20ml | 25ml |

| 30ml | 40ml | 50ml | 100ml | 150ml | 200ml | 300ml |

| 200ml | 300ml | 350ml | 460ml | 500ml | 750ml | 1000ml |

| 1300ml | 1500ml | 2300ml | 3500ml | |||

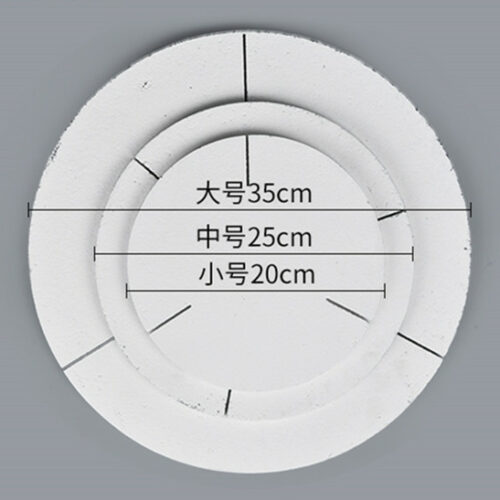

| The crucibles come in both standard and heightened models. There are three types of lids: inner dome lid, outer wrap lid, and flat disc lid. | ||||||

All crucibles support customization services such as drilling, engraving, and slotting.

If you need more detailed information, please contact us immediately. We offer free quotes on all products!

How to Use Alumina Crucibles?

1. Before the first use, preheat the crucible in an oven at around 105°C for 120 minutes to remove moisture.

2. Do not directly heat the crucible with gasoline blowtorch, acetylene torch, or alcohol burner to avoid uneven heating and cracking of the product.

3. The heating or cooling rate should not be too fast. The temperature change below 1200°C should be <5°C/minute, and above 1200°C should be ≤4°C/minute.

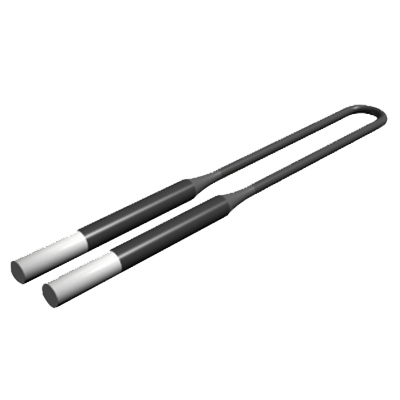

4. The distance between the product and the heating element (such as carbon tube, silicon molybdenum rod, or heating wire, etc.) should be >2cm.

5. The bottom of large crucibles should preferably not directly contact the bottom of the furnace. It is recommended to use alumina foot pads or other heat-resistant materials to lift the crucible, forming air convection to prolong the service life of the product.

Muffle Furnace Crucible Related Products:

Curved Muffle Furnace Crucible

Square Alumina Crucibles for Muffle Furnace

Square Crucible with Lid for Muffle Furnace

Alumina Kiln Furniture for Muffle Furnace