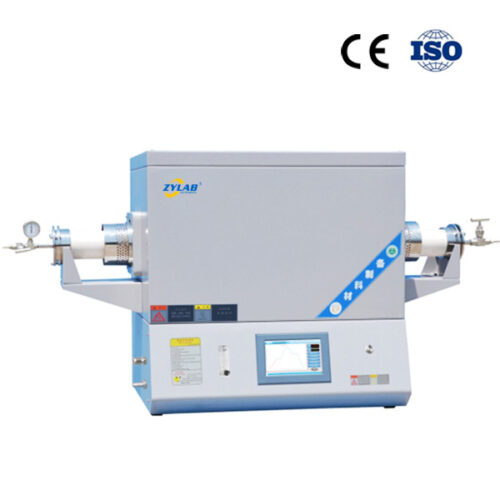

High-Performance Three-Zone PECVD System for Precision Thin Film Deposition

Introduction

The Three-Zone PECVD System, or Plasma Enhanced Chemical Vapor Deposition (PECVD) system, is an advanced thin-film deposition technology widely used in industries such as semiconductors, microelectronics, optoelectronics, and solar energy. The system transforms gases inside a quartz vacuum chamber into ionized states using RF (radio frequency) power. The high-energy electrons in the plasma activate the reactive gases, enabling chemical reactions to occur at lower temperatures, allowing the desired thin films to be deposited onto substrates.

Key Features

- Precise Temperature Control:

The three-zone design allows for more precise temperature control, meeting the different material and process requirements for temperature. With three PID temperature controllers, the temperatures in different zones can be independently regulated, ensuring that the entire deposition process occurs within the optimal temperature range. - Fast Deposition Rate:

Compared to traditional Chemical Vapor Deposition (CVD) technology, the PECVD system offers a higher deposition rate. This is mainly due to the effect of plasma, which enables chemical reactions of the precursor gases at lower temperatures, thus accelerating the deposition process. - Excellent Film Uniformity:

By controlling the frequency of the RF power, the stress level of the deposited film can be precisely adjusted, ensuring uniformity and consistency of the thin film. This precise control is crucial for producing high-quality, high-performance thin films. - High Operational Stability:

The Three-Zone PECVD system utilizes an advanced vacuum system and multi-channel proton mixing gas system, ensuring the stability and reliability of the system. During long-term operation, the system maintains consistent deposition rates and film quality, meeting the demands of large-scale production.

Wide Applications

The system can be widely used for growing nanowires, graphene, and other thin film materials. For example, in the solar cell industry, PECVD technology is used to fabricate high-quality silicon-based thin-film solar cells. In the microelectronics field, PECVD is used to produce various thin films such as SiO2, SiNx, and more.

Technical Parameters

| Model | PECVD-1200-3-4 |

| CVD System | |

| Power Supply | 380V 50HZ, 9KW |

| Tmax | 1200°C |

| Rated Temperature | 1150°C |

| Touch Screen Size | 7″ |

| Temperature Zone Size | 200+200+200mm (Three-Zone, Three-Control) |

| Sensor Type | K-type Thermocouple |

| Furnace Tube Material & Dimensions | High Purity Quartz Tube, Ø801400mm |

| Recommended Heating Rate | ≤10°C/min |

| Mechanical Pump Pumping Rate | 6 m³/h, KF25 |

| Furnace Chamber Ultimate Vacuum | 3~5Pa, with Digital Vacuum Gauge |

| Gas Inlet System | Four-channel Mass Flow Controllers (100sccm, 200sccm, 500sccm, 500sccm) |

| Furnace Body Dimensions | W 1488 H 1275* D 760mm |

| Plasma Generator | |

| RF Frequency | 13.56MHz |

| RF Power Output Range | 0-500W (adjustable) |

| Dimensions | W 275mm × H 380mm × D 430mm |

| RF Power | 500W |

| Control System | 1. Sintering Process Curve Setting: Dynamic display of the process curve, with the ability to store multiple sintering process curves, each of which can be customized.

2. Scheduled Sintering: Enables sintering to run automatically without operator intervention, based on pre-set process curves. 3. Real-time Data Display and Logging: Displays sintering power, voltage, and other relevant information in real-time, with the ability to record and export data for paperless records. 4. Remote Control: Allows for remote operation and real-time monitoring of the equipment status. 5. Temperature Calibration: Non-linear correction of the temperature difference between the main control temperature and sample temperature throughout the sintering process.

|

| Temperature Accuracy | ±1°C |

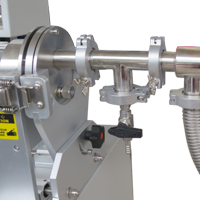

| Pressure Measurement & Monitoring | Uses a mechanical pressure gauge with a gas-tight structure to effectively protect internal components from environmental influences and debris. The gauge also has strong corrosion and high-temperature resistance. |

| Equipment Details |

|

| Net Weight | 280kg |

| Service Support | 1-year limited warranty, with lifetime support (Warranty excludes consumable parts such as processing tubes and O-rings; please order replacement parts from the related products section below). |

For More Options on PECVD System

Please visit our website [PECVD System Collection]