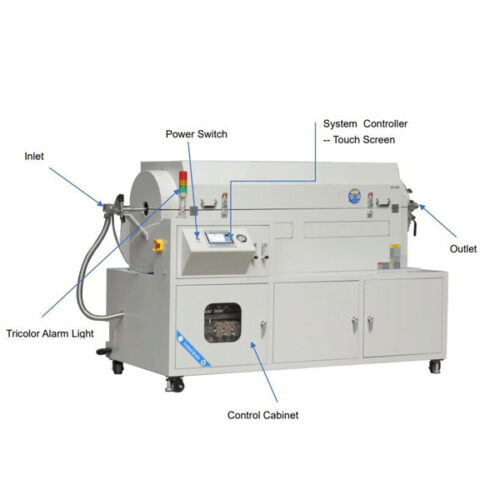

Rotary Powder Calcination Furnace for Battery Material Processing

Introduction

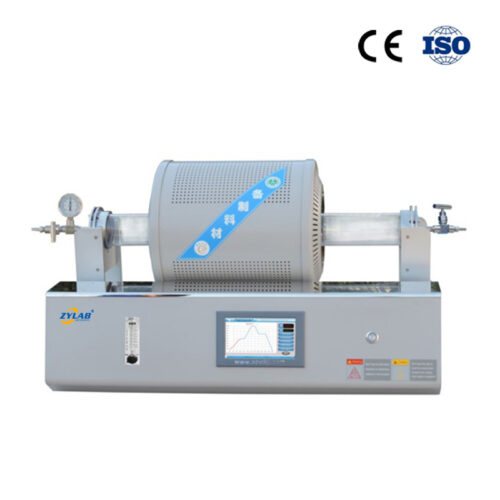

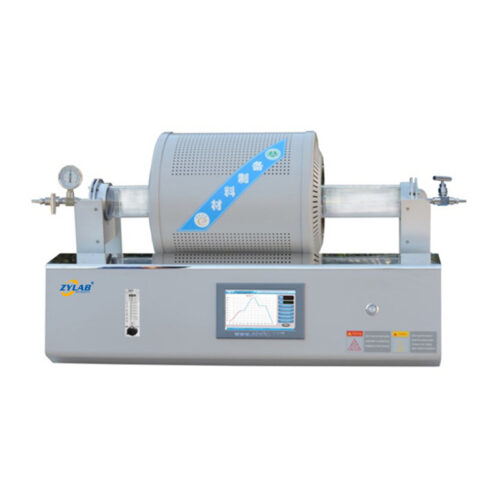

This Rotary Powder Calcination Furnace is a 310S stainless steel inner cylinder externally heated rotary resistance furnace.

It can be used for calcination and drying of granular materials such as lithium battery cathode and anode materials, as well as highly acidic and alkaline powders, in the laboratory pilot stage. Users can apply the appropriate atmospheric protection according to the material firing process.

The production method is batch production, suitable for calcining powder materials.

Structural Description

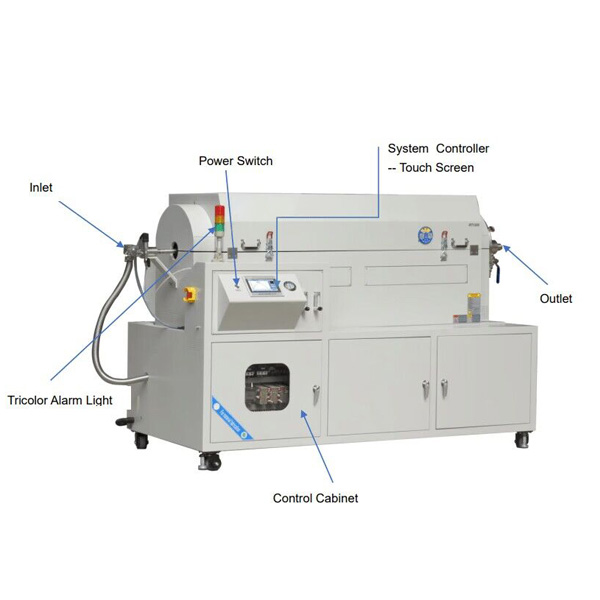

This Rotary Powder Calcination Furnace mainly consists of several parts: furnace body, lifting system, mechanical transmission system, inlet and exhaust system, etc.

1.1 Furnace Body

1.1.1 Furnace Frame: Divided into upper and lower layers, constructed from shaped steel and steel plates. The upper frame is primarily composed of two semi-circular metal shells connected together, containing furnace tubes, refractory material modules, insulation materials, etc. The lower frame houses the electrical control box and electric push rod. The bottom of the lower frame is equipped with four legs: two fixed and two movable wheels with a brake system on the movable wheels.

1.1.2 Refractory Material Modules: Composed made from vacuum-cast alumina alumina fiber.

1.1.3 Metal Furnace Tube: Fabricated from 310S pipes, with internal scraper blades of the same material.

1.1.4 Heating Elements: Constructed from iron-chromium-aluminum heating wire (0Gr27A17Mu2), embedded within the refractory material.

1.2 Lifting System

Controlled by an electric push rod, tilting the upper frame and furnace body within a range of -5° to +15°, capable of hovering at any angle within this range. The maximum positive angle of the upper frame is controlled by the travel switch integrated into the electric push rod. The negative angle is controlled by limit switches installed on the hinge supports, allowing the furnace to stop at any desired angle.

1.3 Mechanical Transmission System

The furnace body is driven by a chain transmission system, ensuring safety and reliability. The transmission system comprises a main drive motor with gearbox, chains, large and small sprockets, and front support wheel mechanism. The gearbox, with a power of 0.12 kW, allows the furnace tube speed to be adjusted between 1 to 3 rpm as required, enabling continuous rotation.

1.4 Inlet and Exhaust System

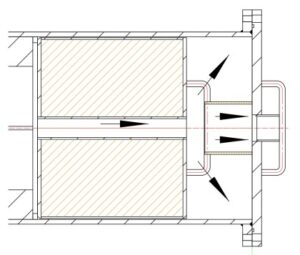

Both ends of the furnace body are equipped with rotary joints for smooth transition. The intake end of the furnace tail is equipped with pipe supports, stainless steel pipelines, ball valves, etc. Protective gas can be introduced as required during material calcination. The furnace door’s rotary head is connected to a ball valve and nozzle, allowing adjustment of the valve opening to control gas discharge based on the volume of material being processed. The flange sealing structure at the discharge port utilizes O-ring silicone seal.

1.5 Control System

The control box is located within the lower frame of the furnace body, housing electrical components such as air switches, power adjustment modules, etc. The controller is positioned at the front of the furnace body, allowing pre-programming of firing curves and fully automated heating. This system facilitates rotation of the heating furnace tube and tilting of the furnace body for easy material loading and unloading.

Features and Benefits of Rotary Powder Calcination Furnace

- Stable and Reliable Control: Easy to operate with comprehensive safety measures.

- Advanced PID Self-Learning Fuzzy Control: High-precision temperature control maintained at ±1℃.

- High-Purity Alumina Lightweight Fiber Insulation: Better insulation effect, energy-saving, and consumption reduction.

- Internet of Things (IoT) Functionality (WIFI): Remote monitoring and operation via smartphone or computer.

- Data Storage Function: Stores important sintering parameters for up to 30 days (8 hours per day).

- Recipe Function: Can store over 20 recipes.

- Networking Function: Connects to the upper computer via RJ45 interface using TCP/IP protocol (upper computer requires corresponding software).

- Unique Loading and Unloading Design: Ensures convenient loading and unloading even in complex structural conditions.

- Integrated Heating, Vacuum, and Rotational Vibration Systems: All-in-one system with a 7-inch full touch screen for convenient and intuitive operation.

- Multiple Process Parameter Storage: Parameters can be saved and retrieved at any time.

- Automatic Screenshot of Experimental Data: Supports USB interface for data export.

Technical Parameters of Rotary Powder Calcination Furnace

| Type | Equipment Technical Specifications | ||||

| Heating system

|

Furnace dimensions | L×W×H=2060mm×1080mm×1580mm (subject to actual dimensions) | |||

| Reaction Muffle Dimensions | 310S stainless steel, inner diameter 309mm × 1250mm, 310S insulation screen sealed, wall thickness 8mm | ||||

| Operating Temperature | ≤1100℃ | ||||

| Effective Volume | 30L when horizontally sintering in the furnace tube, 20L~25L when sintering with up-and-down oscillation | ||||

| Heating Rate | Recommended ≤20℃/min | ||||

| Heating Element | HRE resistance heating wire | ||||

| Furnace Chamber Material | Alumina fiber insulation refractory material | ||||

| Temperature Zone Length | 400+400+400mm | ||||

| Temperature Control Precision | ±1℃ with automatic temperature correction function | ||||

| Sealing Method | Self-pressurizing, rotary sealing | ||||

| Temperature Measurement Element | K-type thermocouple (3 sets of thermocouple control mode for more uniform temperature control)) | ||||

| Gas system configuration | Flow Meter Type | 2-way rotameter (selectable range) | |||

| Pressure Gauge | Mechanical vacuum pressure gauge | ||||

| Regulating Valve Type | Manual regulating valve | ||||

| Pipeline Connection Method | Double ferrule PTFE pipe connection (φ6.35) | ||||

| Pressure Range | -0.1 to 0.15 MPa (absolute pressure) | ||||

| Vacuum system | Vacuum Pump Type | Direct drive rotary vane vacuum pump (dual-stage rotary vane)

|

|||

| Pumping Speed | 14.4m³/h | ||||

| Inlet/Exhaust Connection Port | KF25(mm) | ||||

| Motor Speed | 1440(rpm) | ||||

| Operating Ambient Temperature | 5~40℃ | ||||

| Noise Level(dB) | ≤56 | ||||

| Vacuum Gauge Type | Digital vacuum gauge | ||||

| System Ultimate Vacuum | ≤50Pa | ||||

| Bellows Length | 1200mm | ||||

| Rotational System | Transmission Method | Chain transmission mechanism | |||

| Explosion-Proof Motor | Speed-regulated gear reduction motor | ||||

| Tube Rotation Speed | Adjustable from 1 to 3 rpm | ||||

| Tilting Angle | Adjustable from -5 to 15 degrees | ||||

| Control System | Control Mode | 101EP operating system with switchable English/Chinese graphical interface, 7-inch true color touch screen input, intelligent human-machine interaction mode | |||

| Temperature Correction | Non-linear correction of the temperature difference between the furnace temperature and the sample temperature throughout the process | ||||

| Temperature Curve Settings | Main heating can store up to 15 temperature curves, each curve can set 30 segments of “time-temperature curve”, real-time monitoring, dynamically and accurately displaying “time-temperature curve” | ||||

| System Protection | Over-temperature alarm, over-current protection, thermocouple disconnection prompt | ||||

| Safety Protection | Audible and Visual Alarm | Equipped with overpressure and buzzer alarms | |||

| Safety Gas Circuit Control | Automatically cuts off both gas intake devices if the pressure exceeds the set limit | ||||

| Others | Electrical Specifications | Three-phase 380V, 50Hz, 30KW | |||

| Included Accessories | 1 unit furnace tube, 1 set of sealing flanges, 1 unit control cabinet, 1 user manual, miscellaneous tools, etc. | ||||

| Warranty | 12 months warranty for the equipment, 24 months for the touchscreen system, lifetime support. | ||||

| Anti-Clogging Solution for Exhaust Outlet | Exhaust outlet size: 39mm (inner diameter φ32mm). The exhaust structure includes a large sedimentation chamber before the gas exits through the outlet.

|

||||

| Automatic Level Control | The swinging hover feature includes an automatic leveling function. The equipment is equipped with an angle controller, allowing users to set any angle on the screen. The furnace body will automatically elevate to the designated angle. | ||||

Optional:

Impulse Powder Collector, used for auxiliary material collection.

Complete Schematic Diagram as below:

For More Options on Rotary Furnaces

Please visit our website [Rotary Furnaces Collection]