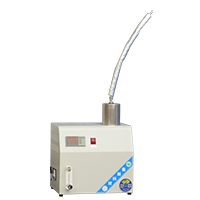

Laboratory Efficient Inert Gas Preheater

Introduction

The inert gas preheater is an electric heating device primarily used to preheat the flow of inert gases entering furnace equipment. The heating element is made of stainless steel heating tubes, and the interior of the heater is equipped with multiple baffles and flow guides to direct the gas flow, extending the gas’s residence time inside the chamber. This ensures the gas is fully heated and evenly distributed, improving heat exchange efficiency. When current flows through the high-temperature resistance wire, the heat generated is transferred to the heating tube surface via crystallized magnesium oxide powder and then transferred to the heated air, achieving the desired heating effect.

Key Features

- High-Temperature Resistant Stainless Steel Tubes are used.

- High Thermal Efficiency, up to 95%, with a temperature control accuracy of ±1°.

- Compact Size, flexible installation, ideal for installation near heating equipment.

Technical Parameters

| Rated Power | 700W |

| Temperature | Range: RT – 700.C(adjustable,can be set through the temperature controller as needed.)

Max. up to 700.C. |

| Heating Rate | ≤30 ℃/min |

| Heating Zone Length | 200mm |

| Inlet | Φ6.35mm |

| Outlet | Φ8mm |

| Flow Range | 0.5-8L/min(other range optional, such as 3-30L/min, 10-100L/min,etc )

The flow rate is adjustable. |

| Dimensions (mm) | L450*H360*D300 |

| Details |  |

| Service Support | One-year limited warranty with lifetime support |

Which kinds of industry can use this Inert Gas Preheater?

College & Universities, New Material Research, New Energy, Powder Metallurgy, Electronics, Ceramic, Chemistry, Medicine,etc.

Applications of Inert Gas Preheater

Furnace and Kiln Operations

Preheating inert gases before entering high-temperature furnaces or kilns to improve energy efficiency and maintain consistent temperatures.

Material Sintering

Used in the sintering process for metal, ceramic, or powder metallurgy, ensuring uniform heating of inert gases, which prevents oxidation and contamination.

Electronics Manufacturing

In the production of semiconductors and other electronic components, where precise temperature control and inert atmospheres are crucial.

Chemical Processing

Used in processes that require inert gas flow, such as chemical vapor deposition (CVD) and plasma-enhanced chemical vapor deposition (PECVD), to ensure uniform gas heating before it enters reaction chambers.

Laboratory Research

Applied in scientific experiments where controlled environments with inert gases are needed, such as material testing, catalysis studies, or controlled atmospheres for reaction kinetics.

Preheating inert gases before they enter vacuum furnace systems to ensure stable operation and improve heat transfer efficiency.

Additive Manufacturing (3D Printing)

Ensures that inert gas is heated to the required temperature to maintain optimal conditions for metal or plastic powder sintering in 3D printing processes

For More Infomation

Please read our blog [Inert Gas Preheater]