Alumina Crucibles High Form for Laboratory

Product Details:

ZYLAB alumina crucibles are made from alumina with a purity greater than 99%, sintered at a high temperature of 1800℃.

The high-form crucibles feature a curved or rounded shape, designed with a smooth concave interior, and have a greater height-to-diameter ratio.This design provides more depth and is useful in applications requiring containment of large volumes of materials while minimizing surface area exposure.

These crucibles offer excellent thermal stability, chemical resistance, and the ability to withstand extreme temperatures, making them ideal for processes involving melting, heating, or chemical reactions in laboratories, as well as in industries such as metallurgy, ceramics, and material science.

We also offer high-form crucibles with lids.

Alumina Purity: >99%

Maximum temperature resistance: 1750°C

Continuous operating temperature: ≤1600°C

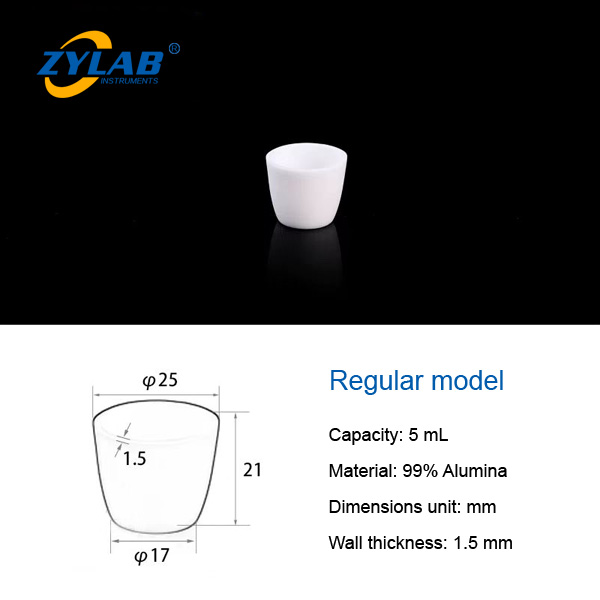

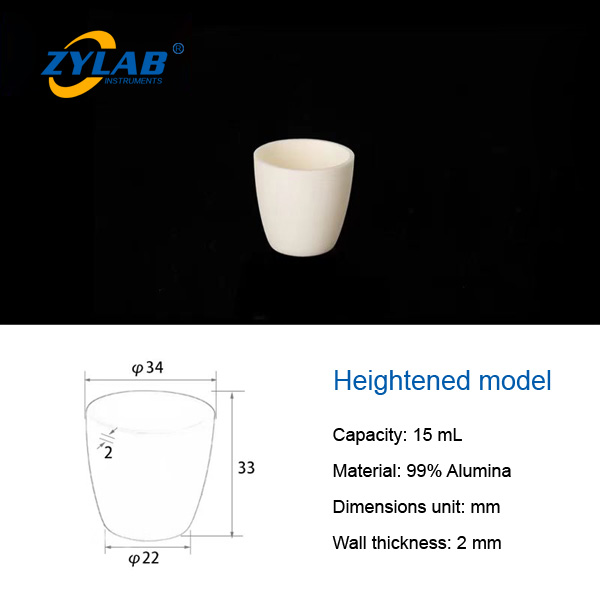

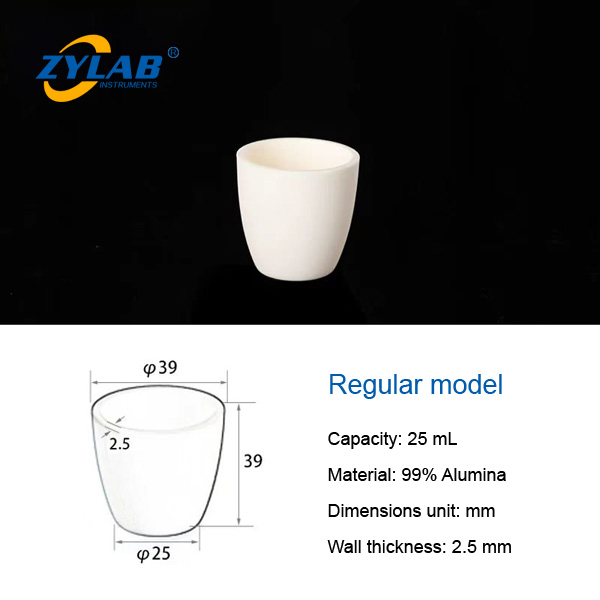

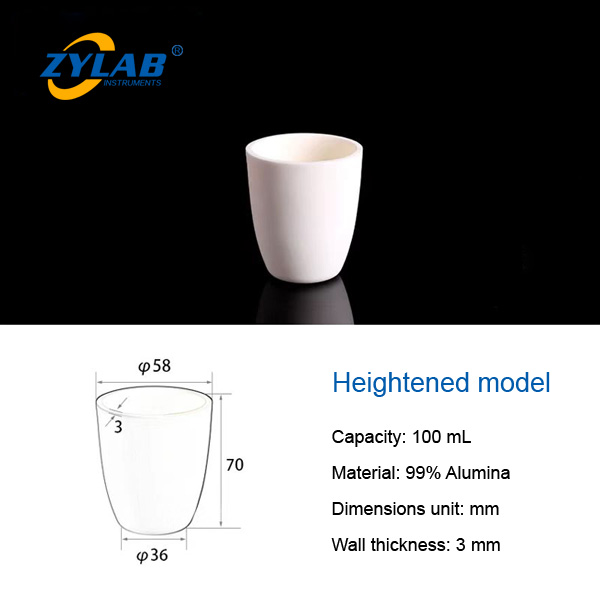

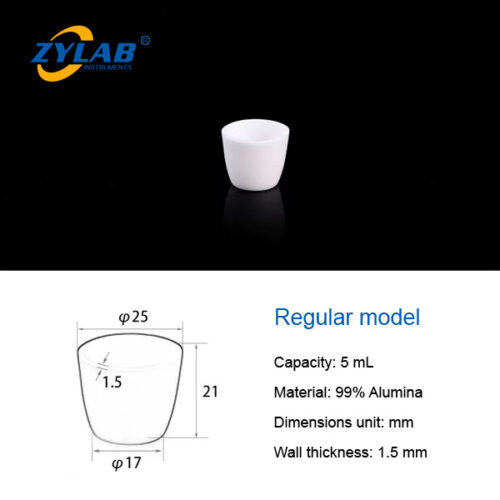

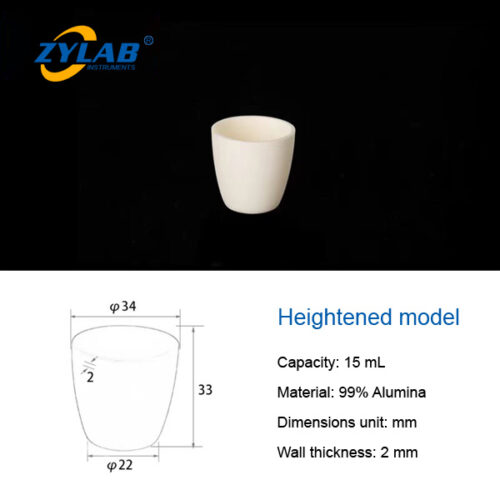

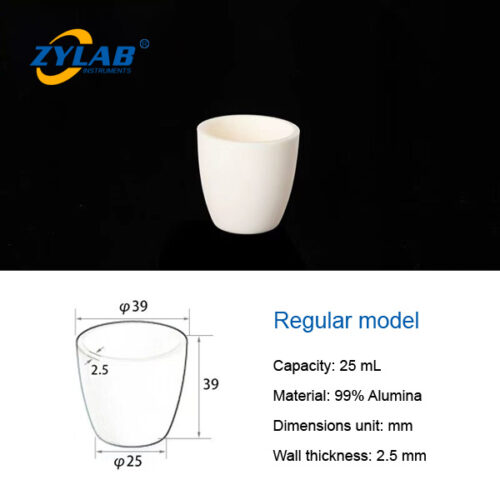

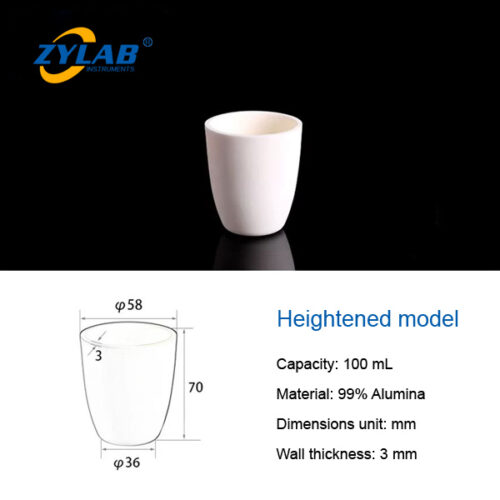

Standard Products and Specifications:

| Specification of Alumina Crucibles High Form | ||||||

| 3ml | 4ml | 5ml | 10ml | 15ml | 20ml | 25ml |

| 30ml | 40ml | 50ml | 100ml | 150ml | 200ml | 300ml |

| 200ml | 300ml | 350ml | 460ml | 500ml | 750ml | 1000ml |

| 1300ml | 1500ml | 2300ml | 3500ml | |||

| The crucibles come in both standard and heightened models, with wall thicknesses ranging from 1.5 mm to 10 mm. | ||||||

The above alumina crucibles dimensions are standard sizes; other sizes can be customized upon request.If you need more detailed information, please contact us immediately. We offer free quotes on all products!

Applications:

Metallurgical Industry: Used for melting and refining metals, especially high-temperature metals and alloys. The high-temperature resistance of alumina makes it perform exceptionally well in these processes.

Ceramic Manufacturing: Suitable for sintering, melting, and powder processing of ceramic materials, ensuring purity and stability of materials at high temperatures.

Chemical Industry: Used in chemical reactors for catalytic reactions, decomposition, or synthesis at high temperatures. The chemical inertness of alumina crucibles allows them to resist most chemical corrosion.

Materials Science Research: Applied in heat treatment, sintering, or melting experiments, helping researchers study the physical and chemical changes of different materials in high-temperature environments.

Laboratory Analysis: In laboratories, alumina high-form crucibles are commonly used in thermal analysis techniques such as Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) to study the thermal stability and composition of materials.

Glass and Optical Materials Production: Used in the production of special glass and optical materials. The high-form design facilitates uniform heating and cooling.

High Purity Alumina Crucibles Notes for Use:

1. Before the first use, preheat the crucible in an oven at around 105°C for 120 minutes to remove moisture.

2. Do not directly heat the crucible with gasoline blowtorch, acetylene torch, or alcohol burner to avoid uneven heating and cracking of the product.

3. The heating or cooling rate should not be too fast. The temperature change below 1200°C should be <5°C/minute, and above 1200°C should be ≤4°C/minute. When cooling, it is recommended to control the temperature by powering off gradually. Cooling too fast during the initial cooling phase after turning off the power may cause the product to crack.

4. The distance between the product and the heating element (such as carbon tube, silicon molybdenum rod, or heating wire, etc.) should be >2cm.

5. The bottom of large crucibles should preferably not directly contact the bottom of the furnace. It is recommended to use alumina foot pads or other heat-resistant materials to lift the crucible, forming air convection to prolong the service life of the product.