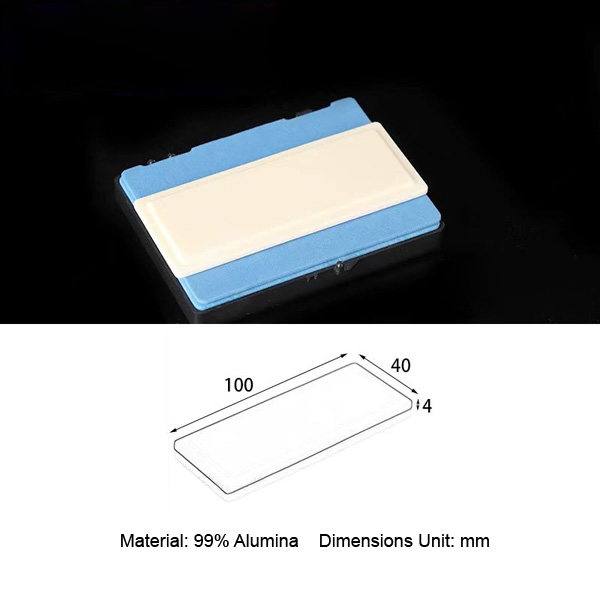

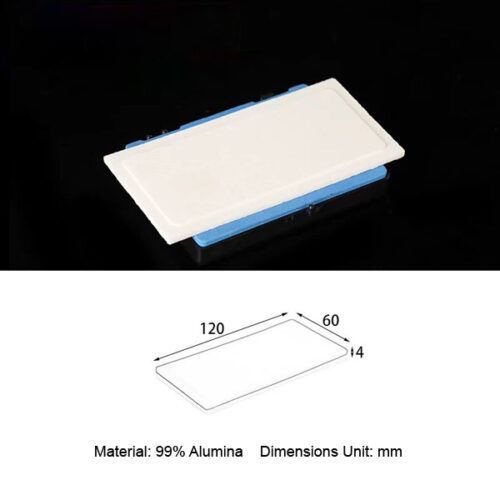

Square High Purity Alumina (Al2O3) Crucible Lids

Product Details:

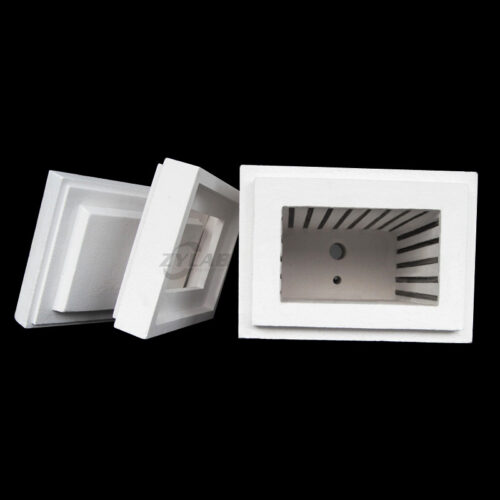

ZYLAB square alumina crucible lids are crucible accessories made from high-purity alumina (Al2O3), specifically designed for high-temperature experiments and industrial environments to protect samples within crucibles.

They are used in conjunction with square alumina crucibles and offer excellent thermal stability and corrosion resistance, making them widely applicable in fields such as metallurgy, ceramics, glass, and material research.

Alumina purity: >99%

Maximum temperature resistance: 1750°C

Continuous operating temperature: ≤1600°C

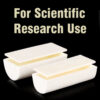

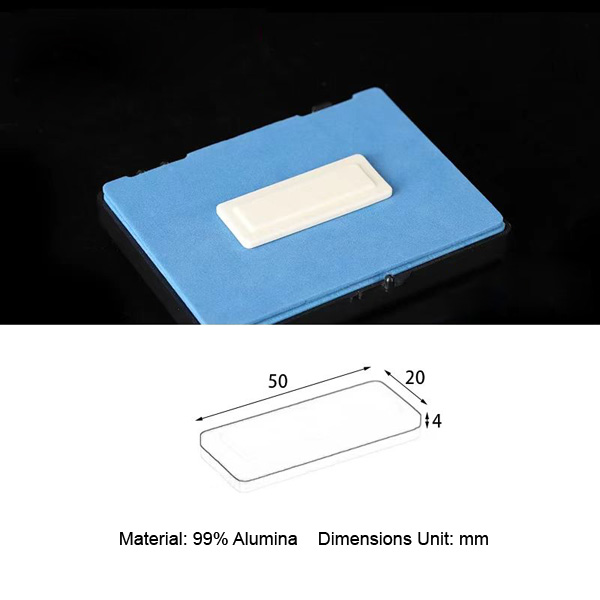

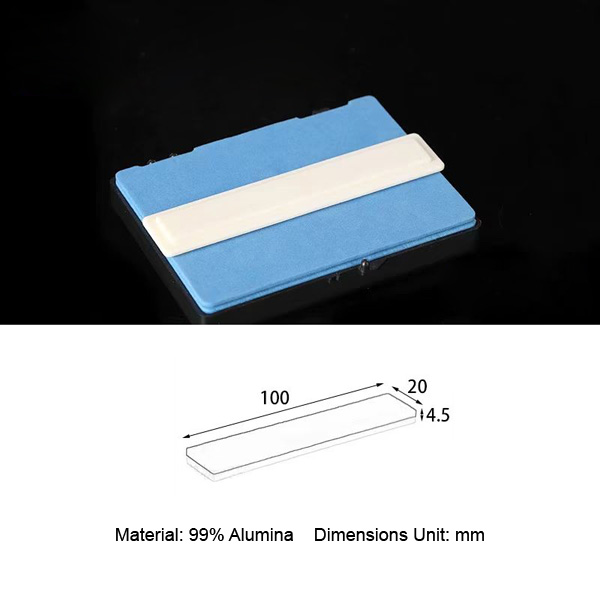

Standard Products and Specifications:

| Square Alumina Crucible Lids Specification (UoM:mm) | |||

| 20×20×3 | 25×15×3 | 30×20×4 | 30×30×3.5 |

| 45×8×2.5 | 45×23×3 | 40×30×3.5 | 50×10×3 |

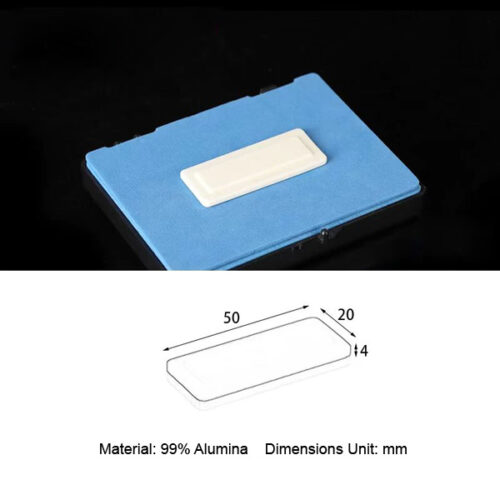

| 50×20×4 | 50×25×4 | 50×50×4.5 | 60×30×5 |

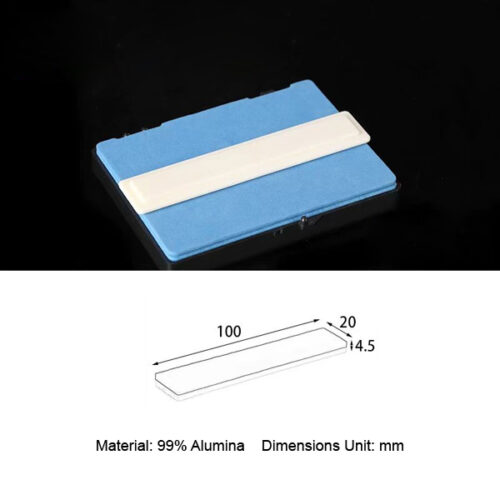

| 80×40×4 | 90×60×5 | 100×20×4.5 | 100×30×4 |

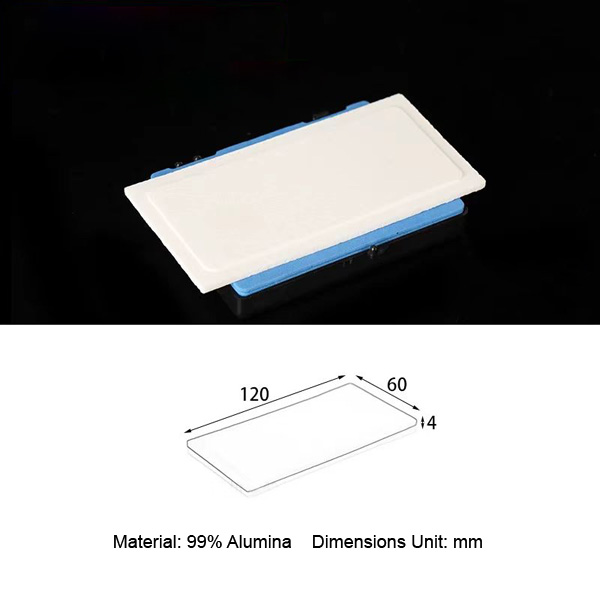

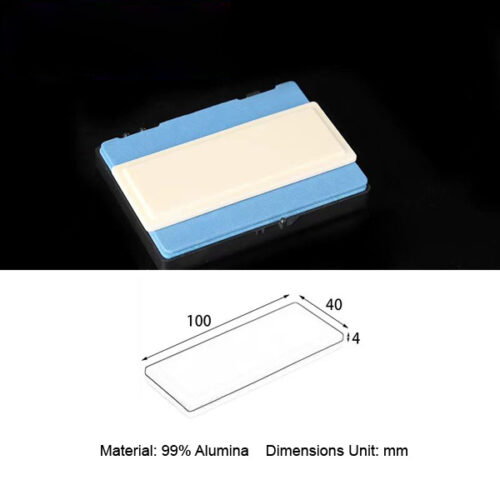

| 100×40×4 | 100×40×8 | 100×50×6 | 120×60×4 |

| 160×160×10 | |||

If you need more detailed information, please contact us immediately. We offer free quotes on all products!

Applications:

Metal Material Processing: Suitable for high-temperature melting, annealing, and alloy manufacturing processes of metals, especially in laboratory and small-scale production environments.

Ceramics and Glass Industry: Used for the sintering of ceramic powders and glass melting experiments at high temperatures, preventing external impurities from entering the crucible.

Chemical Analysis: Commonly used in high-temperature chemical analysis experiments, where alumina crucible lids can prevent samples from contacting external air, reducing the risk of oxidation or evaporation.

Material Research and Development: Widely applied in high-temperature experiments and performance testing of new materials and composite materials, ensuring protection of samples under extreme conditions.

High Purity Alumina Crucibles Notes for Use:

1. Before the first use, preheat the crucible in an oven at around 105°C for 120 minutes to remove moisture.

2. Do not directly heat the crucible with gasoline blowtorch, acetylene torch, or alcohol burner to avoid uneven heating and cracking of the product.

3. The heating or cooling rate should not be too fast. The temperature change below 1200°C should be <5°C/minute, and above 1200°C should be ≤4°C/minute. When cooling, it is recommended to control the temperature by powering off gradually. Cooling too fast during the initial cooling phase after turning off the power may cause the product to crack.

4. The distance between the product and the heating element (such as carbon tube, silicon molybdenum rod, or heating wire, etc.) should be >2cm.

5. The bottom of large crucibles should preferably not directly contact the bottom of the furnace. It is recommended to use alumina foot pads or other heat-resistant materials to lift the crucible, forming air convection to prolong the service life of the product.