Three-Zone Vertical Tube Furnace (Fluidized Bed FBCVD Furnace)

Introduction:

The Three-Zone Vertical Tube Furnace using Fluidized Bed Chemical Vapor Deposition (FBCVD) technology. In FBCVD technology, the reaction occurs within a fluidized bed region inside the furnace. Solid particles exhibit a boiling-like state due to the upward flow of gas, which not only increases the contact area between the material and the reactive gas but also promotes uniform heating and efficient conversion of reactants. This technology is commonly used for the preparation of various materials such as thin films and powders.

This equipment, in addition to the basic features of a standard three-zone tube furnace, has been optimized for fluidized bed reactions. Enhancements include improved gas flow and distribution to ensure a stable fluidized state in the fluidized bed region. In practical applications, it can be used for the growth of advanced materials such as carbon nanotubes and graphene, as well as the preparation and modification of catalysts.

Features and Benefits:

- High-temperature sintering.

- Stable and reliable control, convenient operation, and comprehensive safety measures.

- Advanced PID self-learning fuzzy control, high temperature control accuracy, maintained within ±1℃.

- The furnace lining uses high-purity alumina lightweight fiber material for better insulation, energy saving, and consumption reduction.

- IoT functionality (WIFI) allows remote monitoring and operation of the equipment via mobile phone or computer.

- Data storage function can save important sintering parameters for up to 30 days (8 hours of operation per day).

- Recipe function allows pre-storage of more than 20 recipes.

- Networking capability through an RJ45 interface using TCP/IP protocol, enabling the system to connect with an upper computer (which requires appropriate software installed).

Technical Parameters of Three-Zone Vertical Tube Furnace:

| Model | FB1200-VT3 | ||||

| Tmax | 1150℃ | ||||

| Power Supply | Three phase 380V 50HZ | ||||

| Rated Power | 8KW | ||||

| Quantity of Heating Zone | Three zones and three controls | ||||

| Temperature Control Precision | ±1℃ | ||||

| Sensor Type | K-type thermocouple | ||||

| Temperature Zone Dimensions | φ150*(200+400+200)mm | ||||

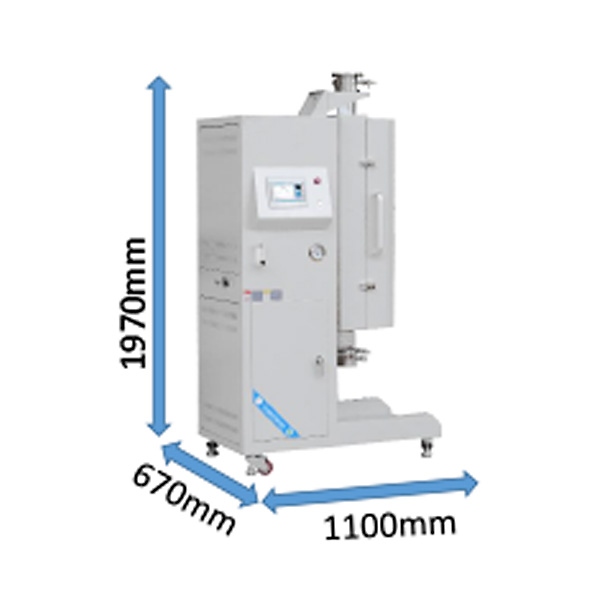

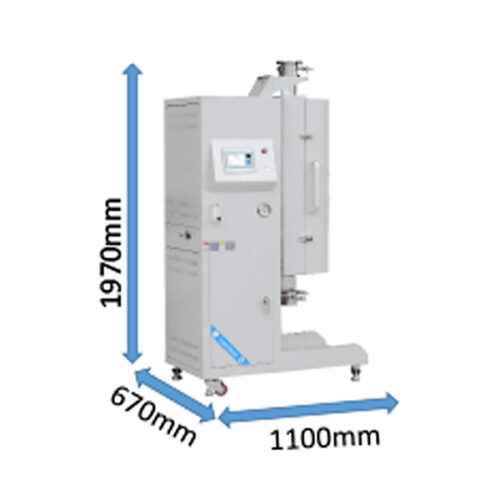

| Furnace Dimensions | L 1100×H 1970×D 670mm | ||||

| Control System |  |

Sintering Process Curve Setting: Dynamically displays the set curve. The device can store multiple sintering process curves, each of which can be freely set.

Sintering Scheduling: Allows for unattended sintering process curve execution. Real-time Display: Displays sintering power, voltage, and other information in real time, records sintering data, and allows for paperless data export. Remote Control: Enables remote operation and real-time monitoring of the equipment status. lTemperature Correction: Non-linear correction of the difference between the main control temperature and the sample temperature throughout the sintering process. |

|||

| Equipment Details |

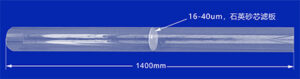

1400 mm high-purity quartz tube with 16-40 µm quartz sand filter plate |

||||

| Heating Elements |  |

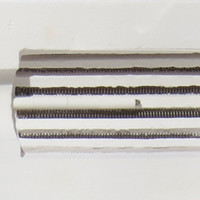

Mo-doped Fe-Cr-Al alloy | |||

| Sealing System |  |

|

|||

| Vacuum Degree: 10 Pa (mechanical pump) | |||||

| Pressure Measurement and Monitoring |  |

Uses a mechanical pressure gauge with a gas-tight shell structure, effectively protecting internal components from environmental impact and debris intrusion, and is highly resistant to corrosion and high temperatures. | |||

| Gas Supply System |  |

Uses a float flow meter to control gas flow rate, integrated with the equipment, and leak-tested before shipment.( Additionally, a more precise proton flow meter can be installed as needed.) | |||

| Net Weight | Approximately 260 kg | ||||

| Service Support | One-year warranty with lifetime support (The warranty does not cover consumable parts such as the process tube and O-rings. Please order replacements in the related products section). | ||||

For More Options on Tube Furnaces

Please visit our website [Tube Furnaces Collection]