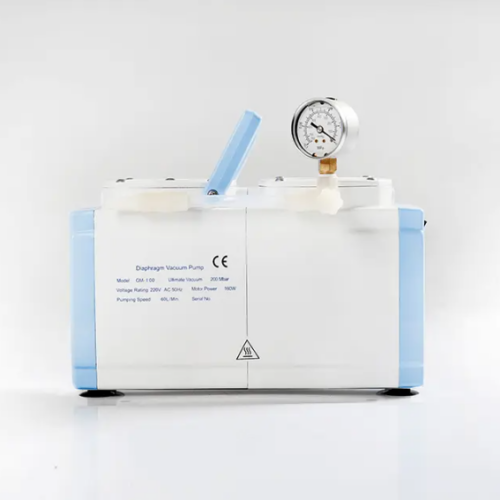

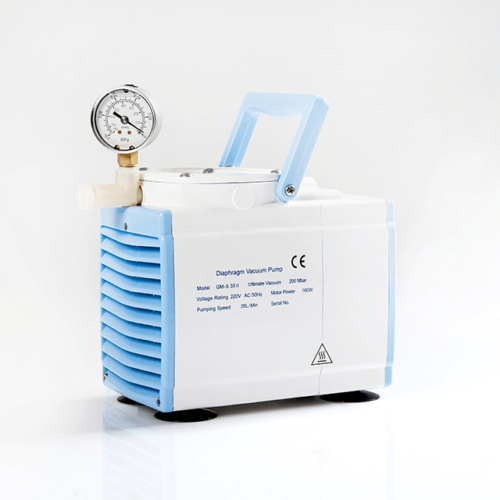

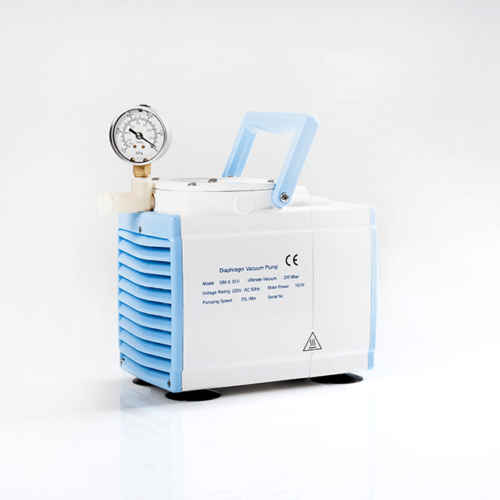

GM-2 High Speed 4cfm Diaphragm Vacuum Pump

Introduction:

GM-2 High Speed 4cfm Diaphragm Vacuum Pump has the features of continuous oil free pumping, low noise level, higher efficiency, long lifetime. It is mainly used in medicinal products and analysis, industry of fine chemicals, biochemical pharmacy, food examination, the criminal investigation technology, etc. It is used with the precision chromatography instrument, the necessary of laboratory. This product is specially designed for laboratory, reliable and easy to use. These Series of products have obtained the national patent.

Characters:

1. The product could work without any medium and does not produce pollution. The gas exchange room is placed with filtering material, to ensure that the air is clean.

2. New material and new technology are adopted in production. It is convenient to move, and work smoothly, thus ensuring the ideal vacuum degree and higher air velocity.

3. Using frictionless membrane body movement, does not produce heat, no friction consumption. Imported rubber diaphragm has long lifetime.

4. Automatic cooling exhaust system is designed in the body, ensures continuous operation 24 hours a day.

5. Adopt imported classic bearing, smooth operation, low noise, high efficiency.

6. Exclusive motor is ODM provided by the professional motor manufacturer and has got the European CE certification. It has the reasonable rotation design, equipped with a power overheat protector. When the pump body temperature reached 130.C, it will automatically power off, to protect the motor from being damaged in the long running work.

7. Small volume and light weight, easy to move, save space, convenient repair and maintenance.

Technical Data of 4CFM Diaphragm Vacuum Pump:

| Model | GM-2 |

| Pumping speed | 120L/Min (4cfm) |

| Ultimate Pressure Vacuum | ≥0.08Mpa(200mbar) |

| Power Supply | 110V/220V/230V/240V |

| Motor Power(w) | 300W (2/5HP) |

| Inlet & Outlet(mm) | Φ9 |

| Temp of the body(.C) | <40℃ |

| Ambient Temp(.C) | 7-40 ℃ |

| Noise Level(DB) | <60 |

| Diaphragm | Nitrile Rubber(NBR) |

| Dimensions(LXWXH)mm | 460*260*400 |

| Weight(kg) | 20 |

| Pump Head | 2 |

| Function | Vacuum & Pressure |

Benefits:

Laboratory oilless vacuum pumps(Diaphragm vacuum pumps) offer several benefits in various applications. Here are some of the advantages:

1. Oil-Free Operation

Laboratory vacuum pumps are designed to operate without the need for lubricating oil. This eliminates the risk of oil contamination, making them suitable for applications where a clean and oil-free environment is required. It is particularly important in industries such as pharmaceuticals, food processing, and electronics manufacturing, where oil contamination can be detrimental.

2. Quiet and Vibration-Free

Laboratory pumps are known for their quiet operation and low vibration levels. This makes them suitable for environments where noise and vibrations need to be minimized, such as laboratories, research facilities, and medical settings.

3. Easy Maintenance

Laboratory pumps are relatively simple in design and have fewer moving parts compared to some other types of vacuum pumps. This makes them easier to maintain and service. They often require less frequent maintenance intervals and have lower maintenance costs compared to pumps that rely on lubricating oil.

4. Compact and Portable

Laboratory vacuum pumps are generally compact and lightweight, making them portable and easy to move around. This feature is beneficial in applications where mobility is required, such as field sampling, on-site analysis, or portable equipment setups.

5. Controllable Vacuum Levels

Laboratory pumps allow for precise control over the vacuum level. This control is particularly useful in applications such as vacuum filtration, where maintaining a specific level of vacuum is essential.

6. Chemical Resistance

Laboratory pumps are available in different materials, including chemically resistant variants. This allows them to handle corrosive gases and vapors, expanding their range of applications in chemical processing and laboratory settings.

7. Energy Efficient

Laboratory pumps generally consume less energy compared to other vacuum pump types, making them more energy-efficient. This can result in cost savings over the long term, especially in applications that require continuous or frequent pump operation.

Applications:

Laboratory vacuum pumps are versatile and find application in various industries and processes. Here are some common applications:

1. Laboratories

Extensively used in laboratories for a wide range of applications, including filtration, degassing, solvent evaporation, vacuum drying, sample preparation, vacuum ovens, and rotary evaporators. Their oil-free operation and precise control over vacuum levels make them ideal for sensitive laboratory processes.

2. Medical and Healthcare

Utilized in medical devices and healthcare applications. They are commonly used in dental suction units, vacuum aspirators, wound drainage systems, vacuum sealing for wound healing, and various diagnostic instruments.

3. Analytical Instruments

In analytical instruments such as gas chromatographs, mass spectrometers, vacuum-based sample concentrators, and vacuum filtration systems. These pumps provide a reliable vacuum source for sample analysis and preparation in analytical laboratories.

4. Environmental Monitoring

In environmental monitoring and sampling devices. The pumps aid in drawing samples and creating a vacuum for analysis or measurement purposes.

FAQ:

Q1: Is the pump noisy?

A1: Compared to some other types of vacuum pumps, diaphragm vacuum pumps are generally known for their quiet operation. They produce lower noise levels and vibrations, making them suitable for applications where noise reduction is important, such as laboratory or medical settings.

Q2: Can a laboratory vacuum pump be operated continuously?

A2: Yes, it can be operated continuously.