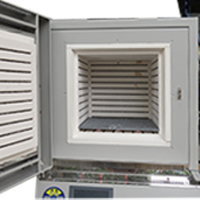

64L 5-Side Heating Box Furnace

Introduction:

The 5-side heating box furnace is an advanced heat treatment device specifically designed to achieve efficient and uniform sintering processes. Its primary feature is the arrangement of heating elements on five sides (excluding the top), ensuring that heat is evenly distributed throughout the furnace chamber. This design effectively eliminates hot spots and enhances the uniformity of sintering, providing comprehensive and uniform heating of samples within the chamber. It is particularly suitable for sintering and heat treatment processes that require strict temperature uniformity. Widely used in materials science research and industrial production, it offers efficient, precise, and controllable sintering solutions for users.

Features and Benefits:

- Five-Side Heating System:

The furnace features high-efficiency heating elements installed on five sides (bottom and four walls), ensuring uniform heat distribution throughout the chamber. This design effectively eliminates hot spots and enhances the uniformity of sintering. - High-Quality Insulating Materials:

The interior of the furnace chamber is typically made from high-purity alumina fiber, which is high-temperature resistant and has a low thermal conductivity. This material offers excellent insulation performance and thermal stability, reducing energy consumption and preventing heat loss, thereby ensuring precise temperature control within the furnace. - Precise Temperature Control System:

Equipped with an advanced PID intelligent temperature control system, it provides high-precision temperature measurement and control capabilities. The system supports multi-segment programming, allowing for precise control over preheating, heating, holding, and cooling stages. - Customizable Atmosphere Control System:

The furnace can be equipped with a gas flow control and mixed gas ratio adjustment system to meet the sintering requirements under oxidizing or other specific atmospheric conditions. - Safety Protections:

The furnace is equipped with multiple safety devices, including over-temperature alarms, thermocouple break protection, and leakage protection, ensuring the safety of both personnel and equipment during operation.

Technical specifications of 5-Side Heating Box Furnace:

| Model | M1200-40(B)IT (Benchtop) | |

| Electrical Specifications | AC380V 50HZ | |

| Rated Power | 10KW | |

| Sensor Type | K-type thermocouple | |

| Tmax | 1200℃ | |

| Long-term Operating Temperature Range | 300~1100℃ | |

| Heating Rate | 1℃/H-20℃/Min | |

| Chamber Dimensions | 400*400*400mm(capacity 64L) | |

| External Dimensions | 856*1100*753mm | |

| Control System |  |

|

| Temperature Accuracy | +/- 1℃ | |

| Heating Elements |  |

Mo-doped Fe-Cr-Al alloy |

| Temperature Zone Testing: |  |

The temperature zone uniformity should ensure minimal temperature differences at various points within the chamber at the set operating temperature. This guarantees uniform heating of samples during the heat treatment process, achieving consistent heat treatment results. To ensure the equipment meets design standards, process requirements, and accurate experimental data while reducing equipment failure risk, a temperature zone test is conducted before shipment. |

| Net Weight | Approximately 350KG | |

| Service Support | 1-year warranty with lifetime support (excluding consumable parts under warranty) | |

Applications:

Here are some common applications for a heating box furnace:

- Sintering Ceramics: Ideal for sintering ceramic materials used in various industrial applications.

- Metal Heat Treatment: Suitable for annealing, tempering, and hardening various metal components.

- Materials Testing: Used in laboratories for testing material properties at high temperatures.

- Glass Processing: Perfect for annealing and tempering glass products.

- Powder Metallurgy: Used for sintering metal powders to create solid metal parts.

- Research and Development: Essential for R&D in materials science, metallurgy, and related fields.

- Electronic Component Manufacturing: Used in the production and testing of high-temperature electronic components.

- Composite Materials: Ideal for curing and processing advanced composite materials..

- Academic Research: Utilized in universities and research institutes for various scientific experiments and studies.

- Jewelry Making: Used for melting and shaping metals in the jewelry industry.

- Additive Manufacturing: Supports post-processing of 3D printed metal parts to enhance mechanical properties.

- Pharmaceuticals: Employed in the development and testing of new pharmaceutical compounds that require high-temperature stability tests.