Table of Contents

Introduction

What is a CVD furnace system?

A CVD (Chemical Vapor Deposition) furnace system is a type of equipment used for the deposition of thin films or coatings onto substrates through chemical reactions at elevated temperatures. It typically consists of various components designed to control the deposition process and ensure the growth of high-quality films.

Key components of a CVD furnace system

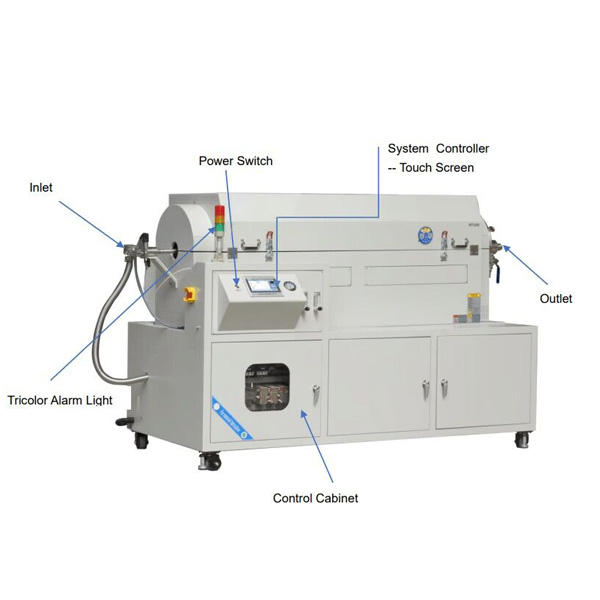

Reactor Chamber: This is the main chamber where the deposition process occurs. It is designed to withstand high temperatures and may be made of materials like quartz or stainless steel. The reactor chamber provides a controlled environment for the chemical reactions between precursor gases and the substrate surface.

Gas Delivery System: Precursor gases and carrier gases are introduced into the reactor chamber through a gas delivery system. This system typically includes mass flow controllers (MFCs) to precisely control the flow rates of different gases. It ensures the accurate composition of the gas mixture required for the deposition process.

Heating Elements: Heating elements are used to raise the temperature inside the reactor chamber to the desired level for film deposition. Common heating methods include resistive heating, inductive heating, or radiant heating. Temperature uniformity across the substrate is essential for uniform film growth.

Substrate Holder: The substrate holder holds the substrates onto which the films will be deposited. It may rotate or move during the deposition process to ensure uniform coverage of the substrate surface. The substrate holder should be compatible with the materials used for deposition and capable of withstanding high temperatures.

Vacuum System: A vacuum system is used to evacuate the reactor chamber and maintain the desired pressure conditions for the deposition process. It typically includes a vacuum pump and associated valves and gauges for controlling the chamber pressure.

Temperature Control System: A temperature control system monitors and regulates the temperature inside the reactor chamber to ensure accurate and stable process conditions. It may include temperature sensors, controllers, and feedback mechanisms to maintain precise temperature control throughout the deposition process.

Gas Exhaust System: Byproducts of the deposition process are removed from the reactor chamber through a gas exhaust system to prevent contamination and maintain a clean environment. It may include scrubbers or filters to neutralize or remove harmful gases before they are released into the environment.

Safety Features: Various safety features such as gas leak detectors, pressure relief valves, and emergency shutdown mechanisms are incorporated into the system to ensure safe operation and prevent potential hazards.

Application

What is a CVD Furnace System Used For?

Semiconductor Device Manufacturing: Used for growing semiconductor thin films, silicon nitride layers, metallization layers, etc., for manufacturing transistors, solar cells, optoelectronic devices, etc.

Surface Coatings and Functional Films: Used for growing corrosion-resistant coatings, hard coatings, conductive coatings, optical coatings, etc., to improve material properties and functionalities.

Nanomaterial Synthesis: Used for growing nanostructured materials such as nanowires, nanoparticles, nanofilms, etc., for applications in nanoelectronics, sensors, catalysts, etc.

Biomedical Applications: Used for growing biocompatible thin films, drug carriers, biosensors, etc., for applications in biomedical detection, drug delivery, etc.

Optics and Photonics: Used for growing optical components, optical waveguides, optical films, etc., for applications in lasers, optical communication, optical sensors, etc.

Energy Storage and Conversion: Used for growing battery electrode materials, photovoltaic materials, fuel cell catalysts, etc., for applications in batteries, solar cells, fuel cells, etc.

The application of CVD furnace systems in the synthesis of nanomaterials

Nanomaterial Growth: CVD furnace systems can precisely control the gas-phase reaction conditions, causing the decomposition of precursor gases at high temperatures and their deposition on the substrate surface, thereby achieving the growth of nanostructures such as nanowires, nanoparticles, and nanofilms.

Size and Morphology Control: By adjusting CVD reaction conditions such as temperature, pressure, and gas flow rate, precise control over the size, morphology, and structure of nanomaterials can be achieved to meet various application requirements.

Multifunctional Nanomaterial Synthesis: CVD furnace systems can be used to synthesize various functional nanomaterials, such as semiconductor nanoparticles, metal nanowires, oxide nanofilms, etc., for applications in nanoelectronics, sensors, catalysts, and other fields.

Heterostructure and Multilayer Structure Fabrication: CVD furnace systems have multiple deposition stages and substrate surface treatment capabilities, enabling the fabrication of complex nanostructures such as heterostructures, core/shell structures, multilayer films, etc., expanding the application areas of nanomaterials.

Large-Area Growth and Scalability: CVD furnace systems have excellent growth scalability, enabling large-area growth of nanomaterials to meet the demands of industrial production and large-scale applications.

What are the advantages of CVD furnace systems?

High Controllability: CVD furnace systems allow precise control over multiple parameters during the deposition process, including temperature, pressure, gas flow rate, and deposition time, thereby achieving precise control over the film growth process.

Diverse Deposition Materials: CVD furnace systems can be used to deposit a variety of materials, including metals, oxides, sulfides, nitrides, etc., to meet the needs of different applications.

High Growth Rate: CVD deposition typically has a high growth rate, capable of producing large-area, uniform films in a relatively short time.

Uniformity and Consistency: Through proper design and control, CVD furnace systems can achieve uniformity and consistency in the film growth process, ensuring stable quality and performance of deposited films.

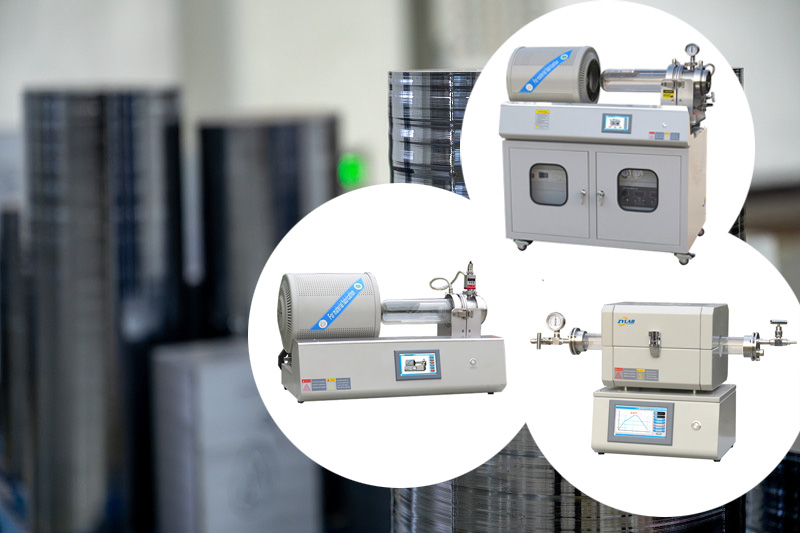

Scalability: CVD furnace systems can be flexibly scaled to different scales and sizes, suitable for laboratory research, small-scale production, and large-scale industrial applications.

Cost-effectiveness: Compared to other deposition techniques, CVD furnace systems typically have lower costs and can operate at higher temperatures, achieving higher deposition efficiency and quality.

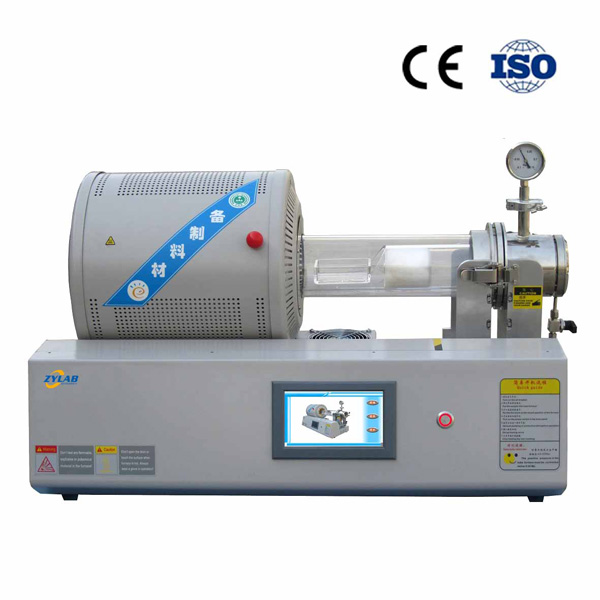

Images for CVD Furnace System

CVD Furnace System Price

The price of a CVD furnace system can vary significantly depending on various factors such as the size, configuration, features, brand, and additional accessories or customization options. Typically, CVD furnace systems can range from several thousand dollars for small laboratory-scale systems to hundreds of thousands or even millions of dollars for larger, more advanced industrial-grade systems. For an accurate price quote, it’s best to contact suppliers directly, as they can provide pricing based on your specific requirements and needs.

FAQ

Q: How should we choose the right CVD furnace system?

A: Choosing the right CVD furnace system depends on various factors including the type of materials needed, the temperature range for growth, types of precursor gases, substrate size and shape, experimental scale, and budget. It is recommended to communicate with suppliers, provide detailed requirements, and receive customized recommendations.

Q: What are the common failures of CVD furnace systems?

A: Common failures of CVD furnace systems include damage to heating elements, gas leaks, temperature control failure, substrate contamination, etc. Timely maintenance and regular inspection can help prevent and address these failures.

Q: How can I optimize growth conditions in a CVD furnace system?

A: Optimizing growth conditions requires experimental design and parameter adjustment based on specific materials and applications. You can try adjusting parameters such as temperature, gas flow rate, reaction time, substrate treatment, etc., to achieve the best growth results.

Q: What are the safety precautions for using a CVD furnace system?

A: When using a CVD furnace system, it is important to follow relevant safety regulations such as handling high-temperature equipment properly, avoiding gas leaks, using protective equipment, ensuring good ventilation, etc. Users should receive proper training before use and follow the operating manual and safety guidelines provided by the supplier.