20L Filtration System for Binder

Introduction:

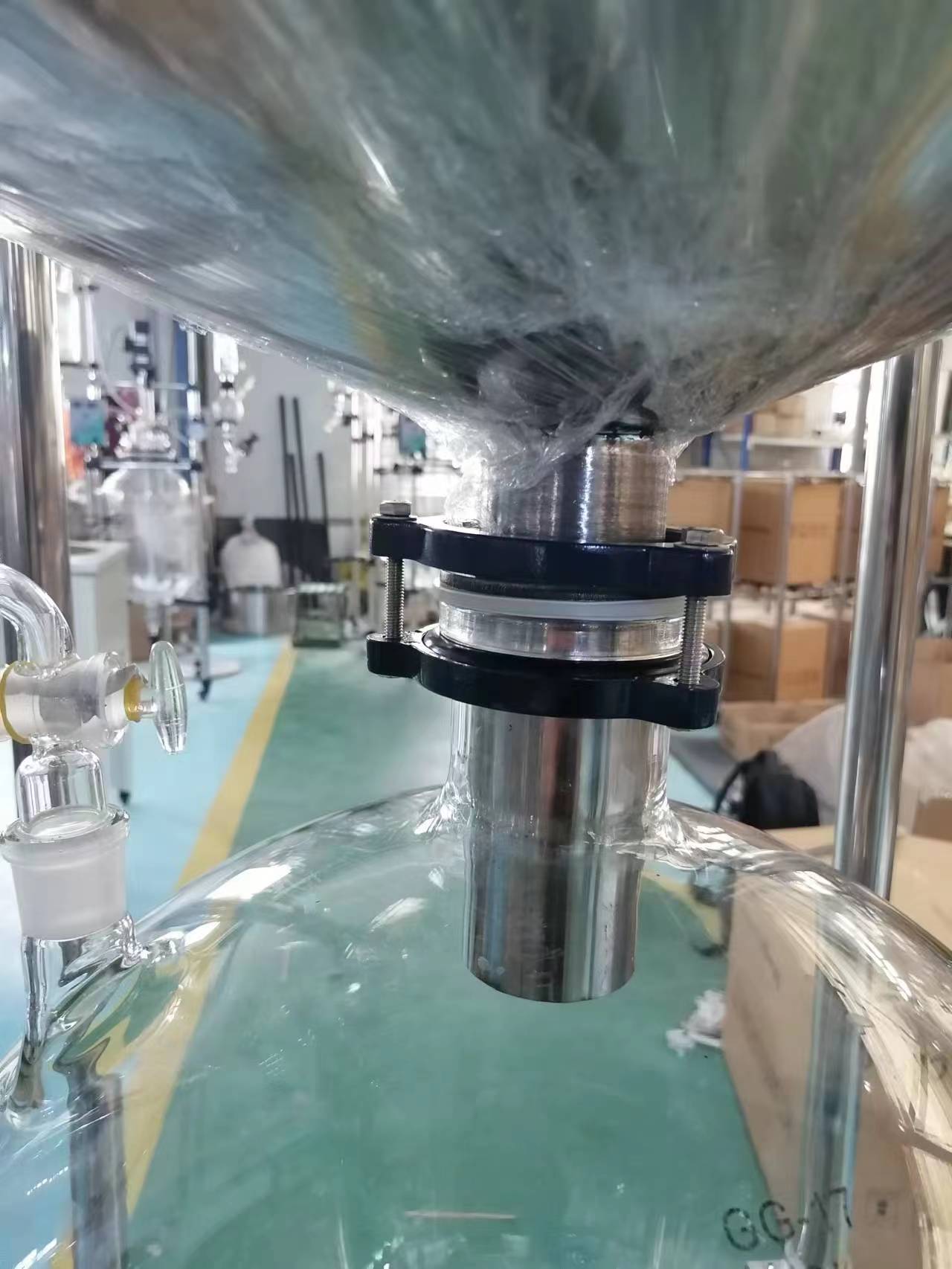

The filtration system series is a 304 stainless steel funnel equipped with different pore size filter materials (filter cloth, filter net, filter membrane, etc.), and the materials that need to be filtered are evenly placed on the filter layer; the glass suction filter bottle is connected to a vacuum pump. The lower glass suction filter bottle is evacuated, and the material in the funnel is filtered by the principle of negative pressure, and the filtered material is pumped into the suction filter bottle. The specific filtered material standard depends on the filter cloth specification.

The suction filter bottles of this series of products are spherical glass bottles, and the commonly used specifications are 10L, 20L, 30L, 50L, 100L, and various specifications can also be customized according to customer requirements.

Main Features:

1. #304 Stainless steel Buchner funnel.

2. Glass transparent discharge valve, quick and easy recovery of solution.

3. The glass suction filter bottle is made of high borosilicate(3.3)grade glass.

4. Double sealed, anti-corrosive.

5. Universal wheel with brake, easy to move.

6. Frame-type main body, the main body is made of aluminum alloy + stainless steel, Compact structure, durable and elegant appearance.

7.10L,20L,30L,50L 100L volume for choose.

Main Specifications:

| Model | VF-20L |

| Capacity Suction Filter Bottle | Spherical 20L,Ф355mm |

| Glass Material | High borosilicate glass 3.3 |

| Frame Material | Aluminum alloy + stainless steel |

| Moving Mode | Universal casters with brake |

| Funnel Size | Ф350*220H(mm), 21L |

| Funnel Material | 304 stainless steel |

| Funnel Connection | 80mm flange mouth |

| Vacuum Connection | 24# Piston valve |

| Discharge Mode | Glass discharge valve,45mm |

| Vacuum Valve | 24# Piston valve. Vacuum nozzle (pagoda joint),outer diameter 12mm. |

| Vacuum Level | 0.098Mpa |

| Discharge Port | 45 ball convex mouth (glass + PTFE core, C valve) outlet 20mm |

| Overall Dimensions | 500(W)*520(D)*1330(H)mm |

| Net Weight | 27kgs |

| Power Supply | 220V 50Hz(or according to requirement) |

| Packing Dimensions | 1380*560*630mm, 0.49m3, wooden box |

| Packing Weight | 53kgs |

Optional turnkey solution:

Vacuum Pump

Microporous Filter Membrane

Which kinds of industry can use this filtration system?

Mainly used in chemistry industrial, pharmaceutical engineering, university experiments, biomedicine, food, scientific research, education and other fields.

Applications:

Filtration System have diverse applications across various industries and scientific fields due to their ability to efficiently separate solids from liquids. Here are some common applications:

- Chemical Processing: Used for filtering chemical solutions to separate solid precipitates or impurities from liquid components.

- Pharmaceutical Production: Employed in pharmaceutical manufacturing for the filtration of drug formulations, separation of crystals, and purification of pharmaceutical products.

- Environmental Analysis: Applied in environmental laboratories to filter water and air samples, aiding in the detection and analysis of pollutants.

- Biotechnology and Life Sciences: Used in biotech labs for various applications, including cell culture harvesting, protein purification, and separation of biomolecules.

- Mining and Metallurgy: Applied in mining processes to separate solids from liquid slurries, and in metallurgical operations for filtering metal-containing solutions.

- Oil and Gas Industry: Employed in the oil and gas sector for filtering crude oil and other fluids to remove impurities and contaminants.

- Wastewater Treatment: Essential in municipal and industrial wastewater treatment plants to separate solids from liquid effluents before discharge.

- Laboratory Filtration: Commonly used in scientific research laboratories for general filtration purposes, sample preparation, and experimental processes.

- Educational Demonstrations: Commonly employed in educational settings to demonstrate principles of filtration and separation processes.