Table of Contents

Rotavapor commonly used in chemical laboratories, is a device utilized to evaporate solvents from solutions, thereby obtaining solutes.

It works by placing the solution in a rotary flask and evaporating the solvent through heating. The evaporated solvent is then condensed back into liquid form through a condenser, thus separating the solutes.

Rotavapor was initially invented by Swiss chemist Lyman C. Craig in the early 1950s. His design involved placing the solution in a rotary flask and rapidly evaporating the solvent through rotation and heating. The evaporated solvent is then recovered through a condenser.

This innovation has been widely successful in chemical laboratories and has become a common method for solvent evaporation, concentration, and purification.

Classification of Rotavapor

Basic Types Classification:

Manual Control Rotary Evaporator: Operators need to manually control parameters such as heating and rotation speed.

Automatic Control Rotary Evaporator: Equipped with automation features, operations can be carried out through preset programs.

Heating Method Classification:

Water Bath Rotary Evaporator: Utilizes water bath for heating the rotating flask to evaporate solvents.

Oil Bath Rotary Evaporator: Uses oil bath as heating medium, ensuring more uniform and stable temperature.

Condensation Method Classification:

Direct Condensation Rotary Evaporator: Uses a condenser to directly cool the evaporated solvent, condensing it back into liquid form.

Condenser Tube Rotary Evaporator: Utilizes condenser tubes to cool the evaporated solvent, typically suitable for recovering volatile solvents.

Application Classification:

Standard Rotary Evaporator: Suitable for routine solvent evaporation, concentration, and purification.

Specialized Rotary Evaporator: Designed for specific application needs, such as working in high temperature or pressure environments.

Size and Capacity Classification:

Laboratory-scale Rotary Evaporator: Used for small-scale laboratory research, typically with smaller flask capacities.

Industrial-scale Rotary Evaporator: Suitable for industrial production, often with larger processing capabilities and capacities.

ZYLAB Rotavapor:

RE-3000 3L rotary evaporator is an up-dated intelligentized product developed based on the technique of Switzerland Buchi company, adopt high speed performance single Chip Microcomputer controlling sector; special controlling process for different controlled object, elegent appearance and stable, reserved connects for special customer’s upgrade requirement. The commonly used specifications are 1L, 3L, 5L.

Mainly used for concentration, crystallization, drying, separation, and solvent recover in various fields such as, pharmaceutical, chemical, and biotechnology industries.

Auto-lifting 20L Rotary Evaporator is designed with large capacity and large opening of evaporating flask, give larger evaporation surface. The evaporating flask keeps rotating when it is constantly heated by water bath, solvent evaporates more efficiently under vacuum condition.The commonly used specifications are 10L, 20L, 50L.

Mainly used for concentration, crystallization, drying, separation, and solvent recover in various fields such as, pharmaceutical, chemical, and biotechnology industries.

Operating Principle

Sample Loading: The liquid sample to be processed is placed into the rotary flask. Typically, these samples are solutions containing dissolved substances.

Rotation: The rotary evaporator rotates the flask at a high speed, typically driven by a motor. The purpose of rotation is to coat the sample onto the inner wall of the flask, increasing the surface area to facilitate solvent evaporation.

Heating: The solution in the rotary flask is heated, usually through a water bath or oil bath. The purpose of heating is to increase the rate of solvent evaporation and accelerate the evaporation of solvents in the sample.

Vacuum Suction: While heating, the rotary evaporator reduces the pressure inside the system through a vacuum system, typically using a vacuum pump. By lowering the pressure, the boiling point of the solvent decreases, thereby promoting rapid solvent evaporation.

Condensation: The evaporated solvent vapor is guided to the condenser. In the condenser, the solvent vapor is cooled and condensed into a liquid state. This converts the solvent from a gaseous to a liquid state, which is then collected in a receiving flask under the condenser.

Solvent Recovery: The liquid collected in the receiving flask is typically the evaporated solvent, which can be further processed and recovered for reuse or further analysis.

How to Choose the Right Rotavapor

Experiment Scale and Sample Volume: Consider the typical sample volume handled in experiments. If it’s small-scale laboratory research, a laboratory-scale rotary evaporator may be sufficient; whereas for large-scale production, an industrial-scale rotary evaporator is required.

Application Field: Different application fields may have different requirements for the performance and functionality of rotary evaporators. For example, some applications may require operation under high temperature or high vacuum conditions, while others may focus more on sample concentration and extraction.

Heating Method and Control Functions: Choose the appropriate heating method, such as water bath or oil bath, according to experimental requirements, and ensure that the rotary evaporator has adjustable heating and rotation speed parameters to meet the requirements under different experimental conditions.

Condensation Method: Select the appropriate condensation method, such as direct condensation or condenser tube, according to experimental requirements, and ensure good condensation performance for effective recovery of evaporated solvents.

Automation and Safety Features: Consider whether an automated control and safety monitoring function is needed for the rotary evaporator to improve experimental efficiency and ensure operational safety.

Ease of Use and Maintenance: Choose a rotary evaporator that is easy to operate and maintain to reduce usage and maintenance costs, and to improve experimental repeatability and reliability.

Budget Limitations: Select a rotary evaporator according to laboratory budget limitations, ensuring that the equipment obtained is suitable in terms of performance and functionality within the budget range.

Brand Reputation and After-Sales Service: Consider choosing a rotary evaporator manufactured by a reputable brand with reliable after-sales service to ensure equipment quality and after-sales support.

Taking all factors into account, it is crucial to select the appropriate rotary evaporator based on experimental requirements and budget limitations. It is advisable to carefully compare different models and brands of equipment before making a selection, and consult with our professional technicians for advice and recommendations.

Routine Maintenance

Cleaning the Operating Panel and Shell: Regularly clean the operating panel and shell of the rotary evaporator, using a soft cloth or sponge to wipe gently, ensuring the instrument’s appearance is clean.

Check the Power Cord and Plug: Regularly check the power cord and plug of the rotary evaporator to ensure there is no wear or damage, avoiding electrical safety hazards.

Check the Rotary Flask and Accessories: Regularly check the rotary flask and other accessories to ensure there are no cracks, wear, or looseness, and replace or repair if necessary.

Cleaning the Rotary Flask and Condenser: Clean the rotary flask and condenser after each use, using a mild detergent and water for cleaning, to prevent solvent residue and sediment accumulation.

Check the Heating Element and Sensors: Regularly check the heating element and temperature sensors to ensure they are working properly, and repair or replace if any faults or damage are found.

Check the Vacuum System: Regularly check the vacuum system’s pipes, valves, and pump to ensure they are properly sealed, avoiding vacuum leaks, and clean and maintain as necessary.

Calibrate Control Parameters: Regularly calibrate the control parameters of the rotary evaporator, such as heating temperature, rotation speed, and vacuum level, to ensure accuracy and stability.

Replace Consumables: Regularly replace the consumables of the rotary evaporator, such as sealing gaskets, rubber parts, and filter screens, to ensure proper operation and safety.

The Role of Rotavapor in Distillation

Solvent Evaporation: The rotary evaporator evaporates the solvent in the rotating flask by heating. The solute in the solution remains in the rotating flask, achieving the separation of components in the solution.

Sample Concentration: The rotary evaporator evaporates the solvent in the solution, allowing the sample to concentrate. This is particularly useful for handling dilute solutions or samples that require concentration.

Fractional Distillation: In some cases, the rotary evaporator can be used to assist in fractional distillation. By adding additives such as zeolite to the solution, different components can be separated during the evaporation process, achieving the purpose of fractional distillation.

Solvent Recovery: The evaporated solvent vapor is guided to the condenser. In the condenser, the solvent vapor is cooled and condensed into a liquid state. This way, the solvent is converted from a gas to a liquid, and collected in the receiving flask.

Extraction of Target Compounds: The rotary evaporator can be used to extract target compounds from complex mixtures. By adding suitable solvents to the solution, target compounds can be extracted into the solvent, and then evaporated using the rotary evaporator, resulting in concentrated target compounds.

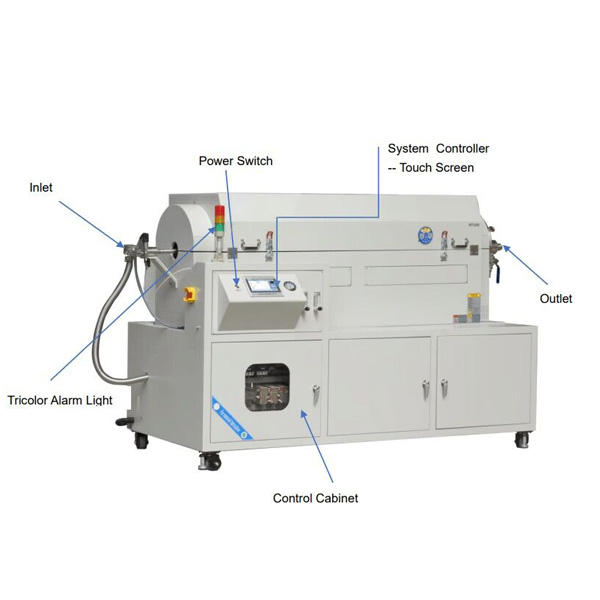

Below are ZYLAB recommended distillation equipment for your reference: