20L Planetary Ball Mill Machine Laboratory Ball Grinding 4x5L

Highlight of 20L Planetary Ball Mill:

1. CE approved. The patented oil seal mute technology, PLC frequency conversion control, adopts the precision gear transmission designed by itself to replace the original belt transmission.

2. Two and four samples can be taken at a time, O-shaped sealed tank, safe operation, pressure resistance.

3. It is suitable for dry/wet/vacuum/protective atmosphere/low temperature/high temperature grinding to ensure the homogeneity and repeatability of the experiment and solve the deposition and adhesion problems of some materials.

4. The equipment is equipped with a safety switch and a safety automatic gear lock. There are universal wheels to push and run, and the equipment is safe and stable.

5. Low center of gravity, stable performance, compact structure, convenient operation, safe and reliable, low noise, no pollution, low loss.

6. The planet main disc is integrated and pressed, with consistent integrity, different from the current market steel plate welding.

7. Planetary gear disc sealing box process, the difference with the market gear exposed at the bottom, and the gear running in the oil sealing box body, running to the highest speed noise can be more than 60% lower than the market ordinary brand, users working in low noise environment, and gear running in the lubricating oil sealing box, less friction coefficient, long gear life, the overall equipment stable life is long.

Product Description:

20L Planetary Ball Mill

Beautiful appearance, easy handling, fine grinding particle size, a good helper in the laboratory.

It is used in colleges and universities, scientific research units and enterprise laboratories to quickly grind research samples to colloidal fineness in batches, and then mix, homogenize and disperse. Widely used in geological, mining, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, beauty, environmental protection and other scientific research and industrial sectors.

Control Panel

The panel has adjustment speed, grinding plan, start and stop emergency stop function, which can be adjusted according to your experimental requirements

Fine Grinding

Complete grinding methods, including dry grinding, wet grinding, high temperature grinding, low temperature grinding, vacuum grinding, protective atmosphere grinding, and the discharge particle size can reach 0.1 um.

Safety Device

In order to avoid emergencies during the experiment, open the lid and make an emergency stop. The instrument will stop running immediately.

Frequency Conversion Control System

The main functions of the planetary ball mill frequency conversion control system are as follows:

1. Forward operation: The planetary disk rotates clockwise.

2. Reverse rotation: The planetary disk rotates counterclockwise.

3. Alternate forward and reverse operation: The planetary disk rotates clockwise and counterclockwise alternately; the alternating forward and reverse operation can improve the uniform mixing and grinding effect of materials.

4. Forward and reverse alternate running time setting: You can set the forward running time and reverse running time.

5. Intermittent operation: The combined grinding method of static and grinding, this grinding method can properly precipitate and cool the material, which is very practical.

6. Intermittent running time setting: Set the static time and running time, which can be determined according to the nature of the material or experience.

7. Speed adjustment: Adjustment of running speed, stepless speed regulation.

8. Running time setting: The setting of the total running time, the maximum duration is 9999 minutes, and the recommended duration is less than or equal to 100 hours.

9. Running: When running, the device works according to the set program.

10. Pause: Stop when running.

11. Power failure memory point recovery: This function is a special function of Miqi planetary ball mill, accidental power failure recovery memory, starting grinding from the power failure point.

12. Safety switch: On/off of the flip safety switch, after setting, it will not affect the normal operation of the device when the flip is opened or closed.

13. Restore settings: Can restore factory settings.

After the control system program is set, the set function will be retained, and the next time it is turned on, it will run according to the last running program.

Technical Details:

| Name | 20L Planetary ball mill |

| Model | M-20L(Oil seal mute) |

| Field of Application | Pharmaceuticals, food, geology, metallurgy, agriculture, glass, ceramics, aviation chemicals, biology, materials, lithium power, electronics, plants, biology and so on. |

| Feed Material | Medium or low hardness, hard, brittle, fibrous, viscous. |

| Size Reduction Principle | Impact, friction |

| Application | Pulverizing, grinding, mixing homogenizing, mechanical alloying |

| Main Disk Structure | Planetary main disk gear soaked in lube oil, reduce noise. |

| Standard | CE |

| Electrical Description | 380V AC ,50-60Hz,3KW |

| Material Feed Size | < 5 mm soil<10 mm |

| Final Fineness | < 100 nm |

| Batch Size / Feed Quantity | 4 x 5L |

| Grinding Jar Sizes | 50 ml /100 ml / 250 ml / 500 ml/1000ml/2L/3L/5L |

| Vacuum Jar Size | 250 ml /500ml/1000ml/2L/3L/5L( Stainless steel) |

| Feed Material Capacity | 660ml |

| Feed balls Capacity | 660ml |

| Sun Wheel Speed | 10 – 320 r/min |

| Ball Mill Jar Speed | 20 – 640 r/min |

| Total Grinding Speed | 960 /min |

| Speed Ratio | 1:2 |

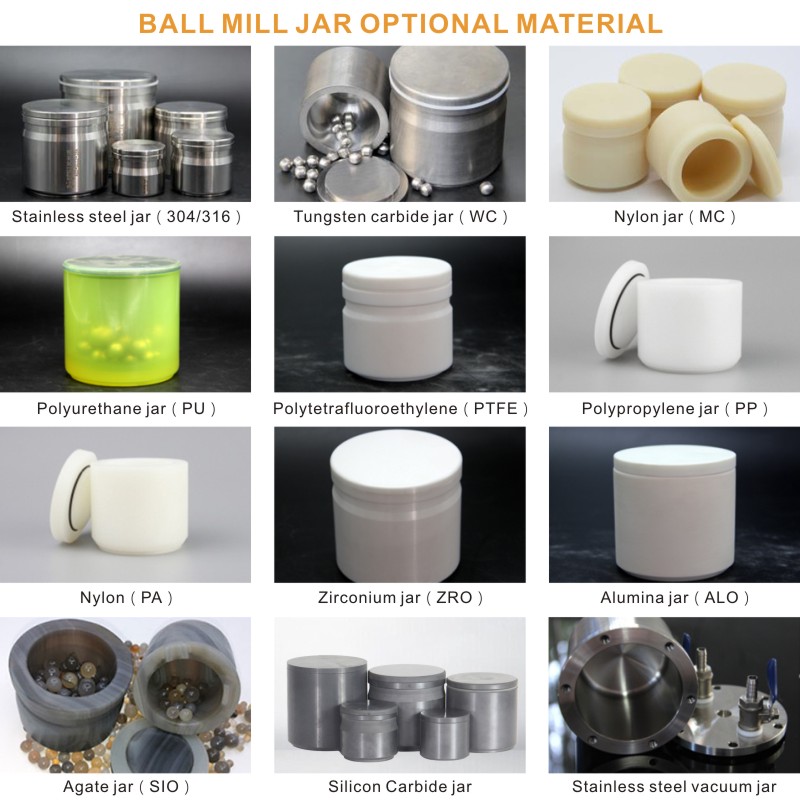

| Material of Grinding Tools | Stainless steel, agate, zirconia, corundum, tungsten carbide, nylon, polyurethane, polytetrafluoroethylene, silicon carbide, etc. |

| Ball Size | 1 / 2 / 3 / 5 / 8 / 10 / 15 / 20 / 25 / 30 mm |

| No. of Grinding Stations | 2 or 4 |

| Mode | Vertical planetary |

| Grinding Mode | Dry/wet |

| Low Temperature Cooling Treatment | Yes (air cooler added) |

| Oil Seal Position | The bottom of planetary main disk |

| Oil Seal Capacity | 800ml(fill in before using the planetary ball mill) |

| Noise | < 60dB(Within 3 metre) |

| Protection Code | IP60 |

| CN Patent | Safety protection (No.ZL 2015 2 0836150.6) |

| CN Patent | Oil seal silent (Patent No.ZL 2014 2 0375569.1) |

| CN Patent | Frequency control(patent No.ZL 2016 2 0836150.6) |

| W x H x D Closed | 100*73*78cm |

| Net Weight | 260kgs |

Other Models:

| Model | Voltage | Motor power(KW) | Inverter power KW | Total timing

(min) |

Alternating Run Time | RPM | Noise ≤db | |

| Revolution speed | Rotation speed | |||||||

| M-0.4L | 220V 50HZ | 0.55 | 0.55 | 1-9999 | 1-9999 | 5-450 | 10-900 | 《50db |

| M-1L | 220V 50HZ | 0.55 | 0.55 | 1-9999 | 1-9999 | 5-450 | 10-900 | 《50db |

| M-2L | 220V 50HZ | 0.75 | 0.75 | 1-9999 | 1-9999 | 5-400 | 10-800 | 《50db |

| M-4L | 220V 50HZ | 0.75 | 0.75 | 1-9999 | 1-9999 | 5-400 | 10-800 | 《50db |

| M-8L | 220V 50HZ | 1.5 | 1.5 | 1-9999 | 1-9999 | 5-320 | 10-640 | 《58db |

| M -10L | 220V 50HZ | 1.5 | 1.5 | 1-9999 | 1-9999 | 5-320 | 10-640 | 《58db |

| M -12L | 380V 50HZ | 1.5 | 2.2 | 1-9999 | 1-9999 | 5-320 | 10-640 | 《58db |

| M-16L | 380V 50HZ | 2.2 | 2.2 | 1-9999 | 1-9999 | 5-280 | 10-560 | 《58db |

| M-20L | 380V 50HZ | 3.0 | 3.7 | 1-9999 | 1-9999 | 5-230 | 10-460 | 《60db |

| M-40L | 380V 50HZ | 5.5 | 7.5 | 1-9999 | 1-9999 | 5-220 | 10-440 | 《63db |

| M-60L | 380V 50HZ | 7.5 | 7.5 | 1-9999 | 1-9999 | 5-180 | 10-360 | 《65db |

| M-80L | 380V 50HZ | 7.5 | 11 | 1-9999 | 1-9999 | 5-180 | 10-360 | 《65db |

| M-100L | 380V 50HZ | 11 | 11 | 1-9999 | 1-9999 | 5-180 | 10-360 | 《68db |

Matched Ball Mill Jars:

| Model | Spec | With ball mill jar | Remarks | |

| Spec(ml) | Quantities | |||

| M-0.4L | 0.4L | 50-100ml | 2 or 4 | With 50ml vacuum ball mill jar |

| M-1L | 1L | 50-250ml | 2 or 4 | With 50-100ml vacuum ball mill jar |

| M-2L | 2L | 50-500ml | 2 or 4 | With 50-250ml vacuum ball mill jar |

| M-4L | 4L | 50-1000ml | 2 or 4 | With100-500ml vacuum ball mill jar |

| M-8L | 8L | 500-2000ml | 2 or 4 | With250-1000ml vacuum ball mill jar |

| M-10L | 10L | 500ml-2.5L | 2 or 4 | With 250-2.5L vacuum ball mill jar |

| M-12L | 12L | 1L-3L | 2 or 4 | With 500-3L vacuum ball mill jar |

| M-16 | 16L | 1L-4L | 2 or 4 | With 500-4L vacuum ball mill jar |

| M-20L | 20L | 1L-5L | 2 or 4 | With 1000-5L vacuum ball mill jar |

| M-40L | 40L | 4L-10L | 2 or 4 | With 3L-10L vacuum ball mill jar |

| M-60L | 60L | 6L-15L | 2 or 4 | With 5L-15L vacuum ball mill jar |

| M-80L | 80L | 6L-20L | 2 or 4 | With 5L-20L vacuum ball mill jar |

| M-100L | 100L | 10L-25L | 2 or 4 | With 9L-25L vacuum ball mill jar |

Detail Applications of 20L Planetary Ball Mill:

Planetary ball mills are powerful tools used to grind, blend, and mix materials in various scientific and industrial applications. Their versatility and efficiency make them valuable tools for a wide range of processes. Some of the key applications of planetary ball mills include:

Nanomaterial Synthesis:

Planetary ball mills are commonly used for the synthesis of various nanomaterials, including nanoparticles, nanocomposites, and nanostructured materials. The high-energy collisions and milling action in the ball mill facilitate the mechanical alloying and grinding down to the nanometer scale.

Mechanical Alloying:

This process involves the repeated welding, fracturing, and rewelding of powder particles to create alloyed materials with improved properties. Planetary ball mills are ideal for performing mechanical alloying due to their ability to achieve high-energy impacts.

Powder Metallurgy:

Planetary ball mills are utilized in powder metallurgy processes for manufacturing metal powders and producing homogeneous blending of metal and non-metal powders.

Material Testing:

These mills can be used to test and evaluate the mechanical properties of materials. By subjecting materials to high-energy impacts and grinding, researchers can study their behavior under different conditions.

Pharmaceuticals and Drug Development:

Planetary ball mills can be employed in pharmaceutical research to grind, blend, and homogenize active pharmaceutical ingredients (APIs) and excipients for drug formulation.

Ceramics and Glass Industries:

In the ceramics and glass manufacturing sectors, planetary ball mills are used to grind raw materials, enhance mixing, and create uniform suspensions for subsequent shaping and firing processes.

Paints and Coatings:

For the production of paints, coatings, and inks, planetary ball mills can disperse and blend pigments with other components to achieve consistent color and texture.

Battery Materials:

Planetary ball mills are employed in the production of battery materials, such as electrode materials and electrolytes, through mechanical blending and synthesis.

Geology and Mining:

These mills can be used in geology and mining applications to grind rocks, ores, and minerals for sample preparation or mineral liberation.

Catalysis and Chemical Engineering:

Planetary ball mills are used in chemical synthesis and catalytic processes to facilitate mixing, blending, and mechanochemical reactions.

Food and Beverage Industry:

In the food industry, planetary ball mills can be employed for mixing, grinding, and homogenizing ingredients to create products like sauces, pastes, and creams.

Environmental Applications:

Planetary ball mills can be used for the destruction of hazardous waste materials or for wastewater treatment processes.

The above applications demonstrate the versatility of planetary ball mills across various industries and research fields. Their ability to achieve high-energy impacts and mechanical blending makes them indispensable tools for numerous material processing and synthesis tasks.