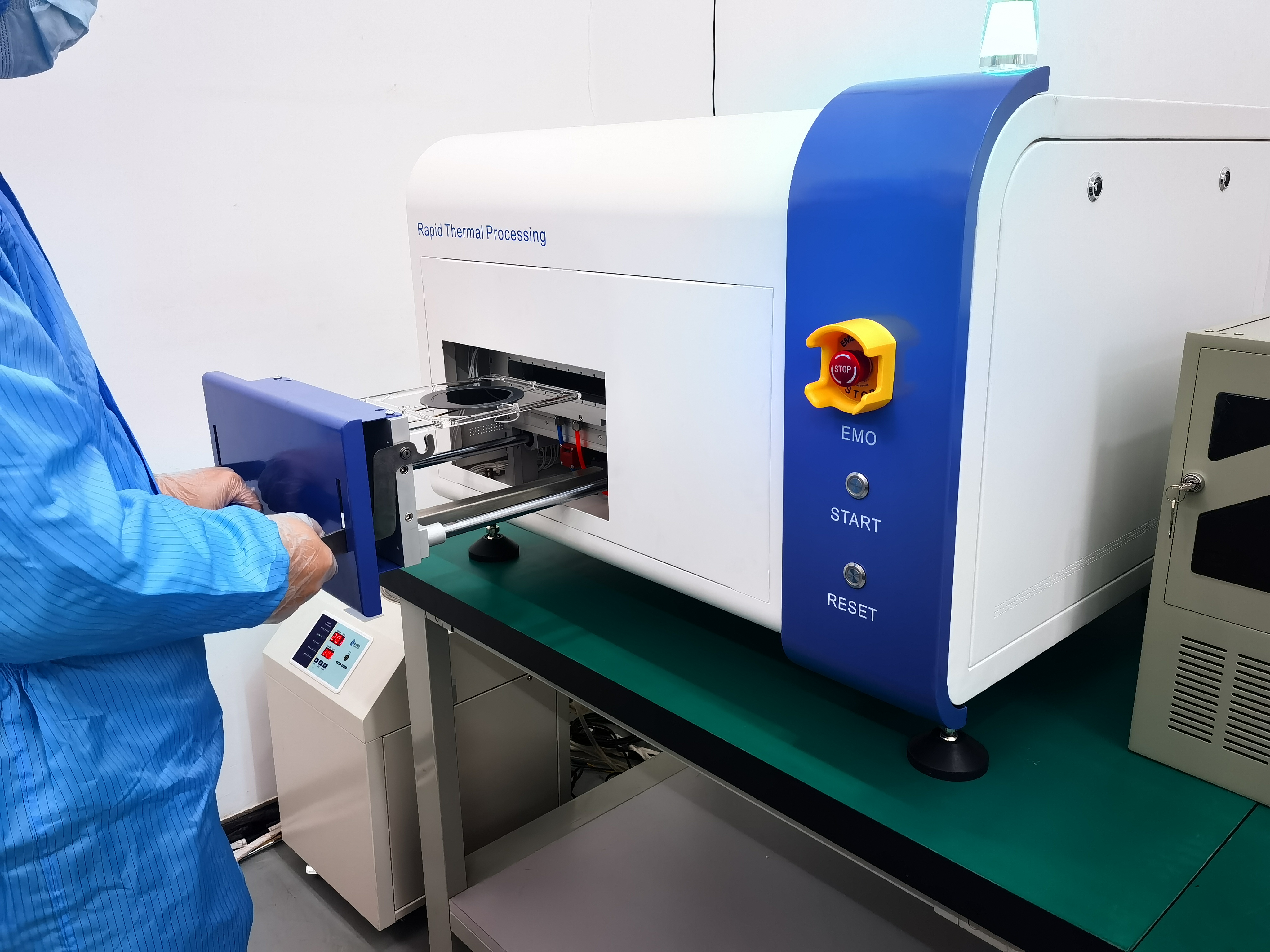

Rapid Thermal Processing Furnace for Semiconductor

Introduction:

This furnace for semiconductor is a desktop manual rapid thermal annealing system operated in a protective atmosphere, designed for infrared-visible light heating of single wafer or samples. With a short processing time, high temperature control accuracy, and compatibility with 2-6 inch wafers, it stands out compared to traditional diffusion furnace annealing systems and other RTP systems. The unique chamber design, advanced temperature control technology, and exclusive RL900 software control system ensure excellent thermal uniformity.

Features and Benefits:

1. Infrared halogen lamp heating with air cooling

2. Lamp power PID temperature control for precise temperature ramping, ensuring good reproducibility and temperature uniformity

3. Parallel gas inlet design, with the gas inlet located on the wafer surface to prevent cold spots during annealing, ensuring excellent temperature uniformity

4. Atmospheric and vacuum processing options, with gas purification treatment before inlet

5. Standard configuration includes two sets of process gases, expandable up to six sets

6. Maximum wafer size for single crystal sample testing is 6 inches (150mm)

7. Features triple safety measures, including furnace door safety temperature opening protection, temperature controller authorization protection, and emergency stop safety protection, ensuring comprehensive instrument safety.

Technical Parameters:

| Item | Specification |

| Maximum Product Size | 6-inch wafer or maximum 150x150mm product |

| Temperature Range | Room temperature to 1250°C |

| Maximum Heating Rate | Up to 100°C/s (excluding the carrier ramping rate), programmable |

| Temperature Uniformity | ±5°C≤ 500°C, ±1% >500°C |

| Temperature Control Accuracy | ±1°C |

| Temperature Control | Rapid PID temperature control |

| Substrate Cooling | Nitrogen blow |

| Process Gas | MFC control, conventional three-gas (N2/O2/Ar) |

| Control Method | Industrial computer + PC control |

Applications(Processes):

- Growth of oxides and nitrides;

- Annealing of silicide alloys;

- GaAs process;

- Rapid alloying for ohmic contacts;

- Reflow oxidation;

- Other rapid heat treatment processes.