Table of Contents

Overview

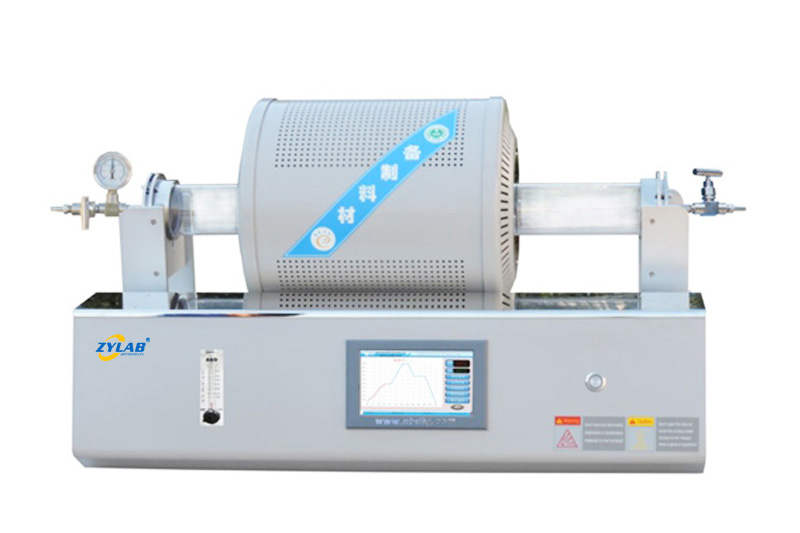

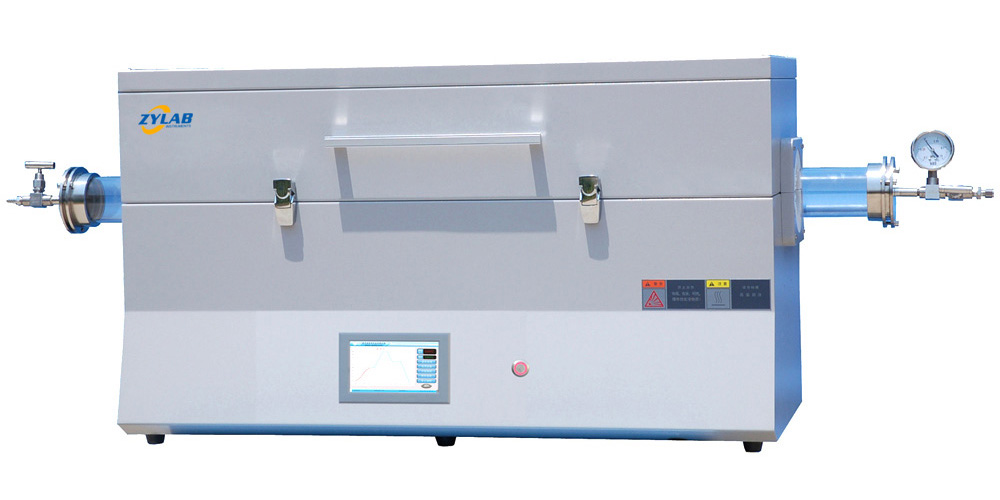

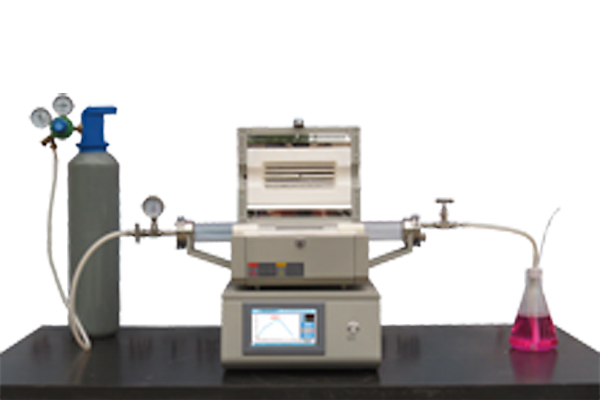

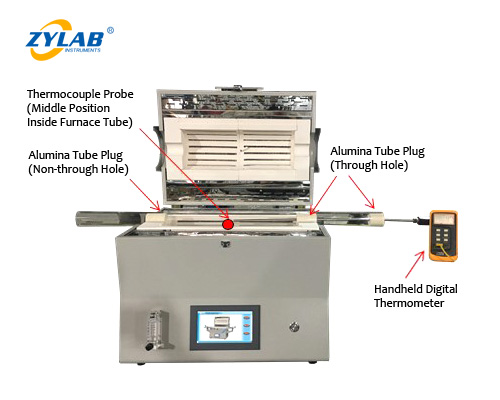

A quartz tube furnace is a specialized high-temperature heating device used for materials processing, chemical reactions, and heat treatment. It features a cylindrical, transparent quartz tube that acts as a high-temperature reaction chamber, with heating elements for precise temperature control.

These furnaces are versatile and find applications in various industries and scientific research.

Features

High-Temperature Capability: Quartz tube furnaces can reach temperatures exceeding 1000°C, making them suitable for a wide range of high-temperature processes.

Uniform Heating: They provide consistent temperature distribution, ensuring materials inside are heated evenly.

Chemical Inertness: Quartz is chemically inert, making it suitable for processes involving corrosive or reactive materials.

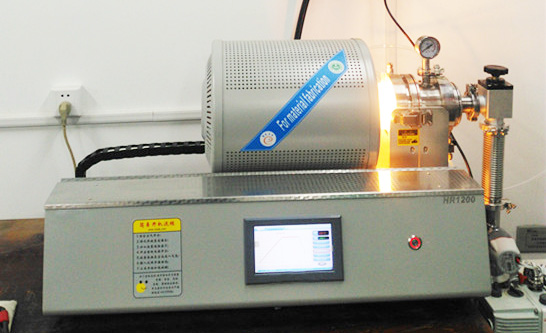

Transparency: The quartz tube allows real-time observation of reactions or materials inside.

Precise Temperature Control: These furnaces are equipped with advanced control systems for accurate temperature regulation.

Safety: Proper safety measures are essential when operating at high temperatures.

Work Process

1. Material or samples are placed inside the quartz tube.

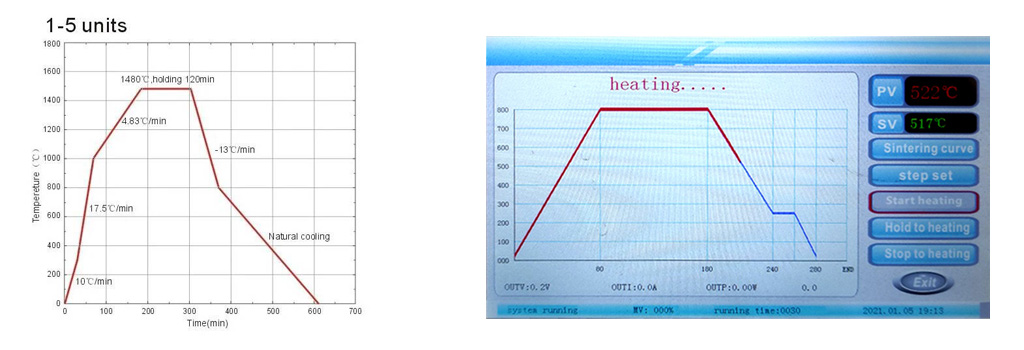

2. The heating elements are activated, and the temperature is gradually increased to the desired level.

3. The materials undergo the desired processes, such as annealing, sintering, or chemical reactions.

4. The temperature can be precisely controlled and maintained throughout the process.

5. After the process is complete, the furnace is allowed to cool down before opening.

Applications

Materials Processing: Used in the production of semiconductors, ceramics, and specialty glasses.

Chemical Reactions: Ideal for chemical vapor deposition (CVD) and other chemical synthesis processes.

Heat Treatment: Used for annealing, sintering, and heat treating various materials.

Research and Development: Widely used in materials science and chemistry research.

Benefits

1. Precise temperature control.

2. Transparent quartz tube for real-time observation.

3. Suitable for a wide range of high-temperature applications.

4. Chemical inertness for handling reactive substances.

Price

The price of quartz tube furnaces can vary widely depending on factors such as size, temperature range, and additional features. Basic models may start around a few thousand dollars, while more advanced and larger furnaces can cost tens of thousands of dollars or more.

Considerations When Purchasing

Temperature Range: Ensure the furnace can reach the required temperature for your specific applications.

Size and Capacity: Choose an appropriate size to accommodate your samples.

Temperature Control: Look for precise and reliable temperature control systems.

Safety Features: Consider safety measures, including overheat protection, over- current protection, broken-thermocouple protection.

Transparency: Evaluate the quality of the quartz tube for optimal observation.

Price and Budget: Determine your budget and find a furnace that meets your requirements within that budget.

FAQ

1. Is it safe to use a quartz tube furnace at high temperatures?

Yes, when used with proper safety measures, including ventilation and personal protective equipment.

2. Can I use a quartz tube furnace for melting materials?

It depends on the temperature capabilities of the furnace. Some quartz tube furnaces can be used for material melting.

3. What is the difference between a tube furnace and a muffle furnace?

A tube furnace has a transparent quartz tube for observation, while a muffle furnace has a sealed chamber for uniform heating.

4. Can I use a quartz tube furnace for controlled atmosphere experiments?

Yes, some models can be equipped with controlled atmosphere capabilities.

5. How do I clean a quartz tube furnace?

Follow the manufacturer’s instructions for cleaning and maintenance. Usually, a soft cloth or mild solvents are used for cleaning the quartz tube.