12L 1200.C Programmable Muffle Furnace

Introduction:

The progammable muffle furnace with engineers’ ingenious flat design not only greatly enhance the proportion of space, but also fit most people’s operating habits. Separate heating system and control unit can’t interfere with each other, this can ensure that the electric components and the entire circuit system to maintain a safe and reliable working condition in a sustained high temperature environment. At the same of strict control product quality, we pay more attention to customers’ experience to make the operation easier.

Features and Benefits:

1. Max. Temperature 1200.C, working temperature RT-1100.C.

2. Intelligent 7” color touch screen temperature controller, easy to operate, clear heating process; can store temperature curve to avoid the trouble caused by repeated settings of different experimental processes.

3. 30 segments programmable and auto control.

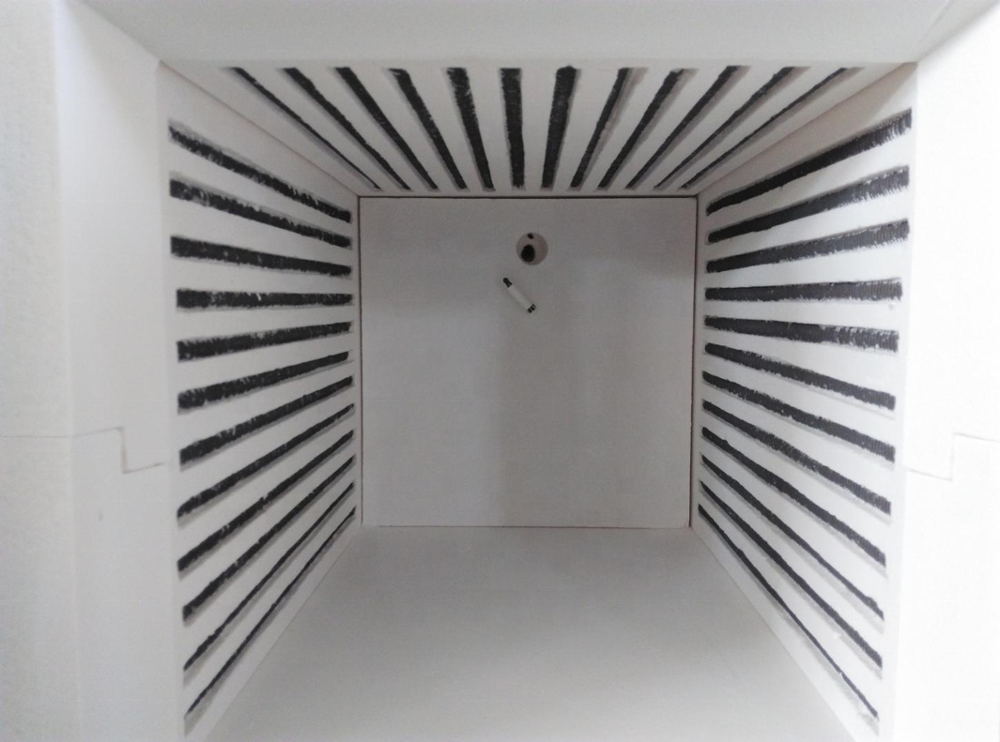

4. Ceramic fibre furnace chamber, to ensure a fast heating rate, and save power.

5. By using special lining import from Japan and high quality alloy heating wire with excellent acid and corrosion resistance, protected against chemical contamination at the best and longer service life.

6. Vent hole carefully designed is the perfect solution to the waste gas during material sintering.

7. Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C, safety for the operator.

8. Low power consumable, exquisite structure and light weight, it is the ideal programmable muffle furnace for material research labs, also used in factory production.

Technical Specifications:

| Model | M1200-20IT |

|

Furnace structure |

•1430 type high purity ceramic fibre insulation (energy saving 40% and weight lighter about 30% than old furnace); • Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C. |

| Chamber size

(working space) |

200*200*300mm |

| Max. temperature | 1200 ℃(<1 hours) |

| Working temperature | Rt -1150 ℃ |

| Intelligent Touch Screen

Temperature controller |

•PID automatic control and auto-tune function. •30 programmable segments for precise control. •Built in protection for over-heated and broken thermal couple, and leakage. •Centralized control 7” color LCD touch screen man-machine English graphics interface, clear heating process, more intuitive and convenient operation.•Can store sintering programs to avoid the trouble caused by repeated settings of different experimental processes. |

| Furnace Lining | Special top quality lining import from Japan, will not pollute the product |

| Heating element | Top quality resistance wire |

| Heating rate | 0~20℃/min |

| Temperature accuracy | +/- 1 ℃ |

| Thermocouple | K type |

| Working voltage | AC 208 – 240V, 50/60 Hz (according to requirement) |

| Max. Power | 4 Kw |

| Dimension | 650(W)*520(H)*600(D)mm |

| Quantity / Net weight | 1set / 60kgs |

| Warranty | 18 months(not including consumable parts, such as heating elements, thermocouple), lifetime support. |

| Certificate | CE, ISO9001 |

Which kinds of industry can use this Programmable Muffle Furnace?

Universities, Chemistry, Medicine, New Materials, Coal Mining, Metallurgy, Electronics,etc.

Applications of Programmable Muffle Furnace:

Here are some common applications:

- Heat Treatment of Metals and Alloys:

- Annealing: Softening metals by heating and then slowly cooling them.

- Tempering: Reducing brittleness of hardened metals by reheating and then cooling them.

- Ceramic Processing:

- Sintering: Compacting and forming a solid mass of material by heat or pressure without melting to the point of liquefaction.

- Glaze Firing: Applying a coating to ceramics and heating to create a glassy surface.

- Material Synthesis and Analysis:

- Combustion Analysis: Determining the content of elements like carbon, hydrogen, and sulfur in materials by burning the sample.

- Thermogravimetric Analysis (TGA): Measuring changes in physical and chemical properties as a function of temperature.

- Glass and Composite Material Research:

- Devitrification: Studying the process of crystallization in glass.

- Heat Treating Composites: Improving the properties of composite materials through controlled heating.

- Chemical Synthesis:

- Calcination: Heating a substance to a high temperature in the absence or limited supply of air or oxygen to bring about thermal decomposition.

- Oxidation and Reduction Reactions: Controlling the atmosphere within the furnace for specific chemical reactions.

- Environmental Testing:

- Ash Content Determination: Heating organic materials to burn off combustible components and leaving behind ash.

- Thermal Stability Testing: Evaluating materials’ resistance to heat over prolonged periods.

- Electronics and Semiconductor Industry:

- Doping: Introducing impurities into a semiconductor to change its electrical properties.

- Oxidation: Growing oxide layers on semiconductor wafers.

- Forensic Analysis:

- Fire Debris Analysis: Identifying accelerants in fire debris by burning samples.

- Drug Analysis: Thermal decomposition of substances to identify compounds.

- Geological and Mineralogical Studies:

- Sample Preparation: Preparing rock and mineral samples for analysis by heating.

- Phase Transition Studies: Investigating changes in mineral phases at different temperatures.

- Biological and Medical Research:

- Sterilization: Using high temperatures to sterilize equipment and materials.

- Material Decomposition Studies: Analyzing the thermal degradation of biological materials.