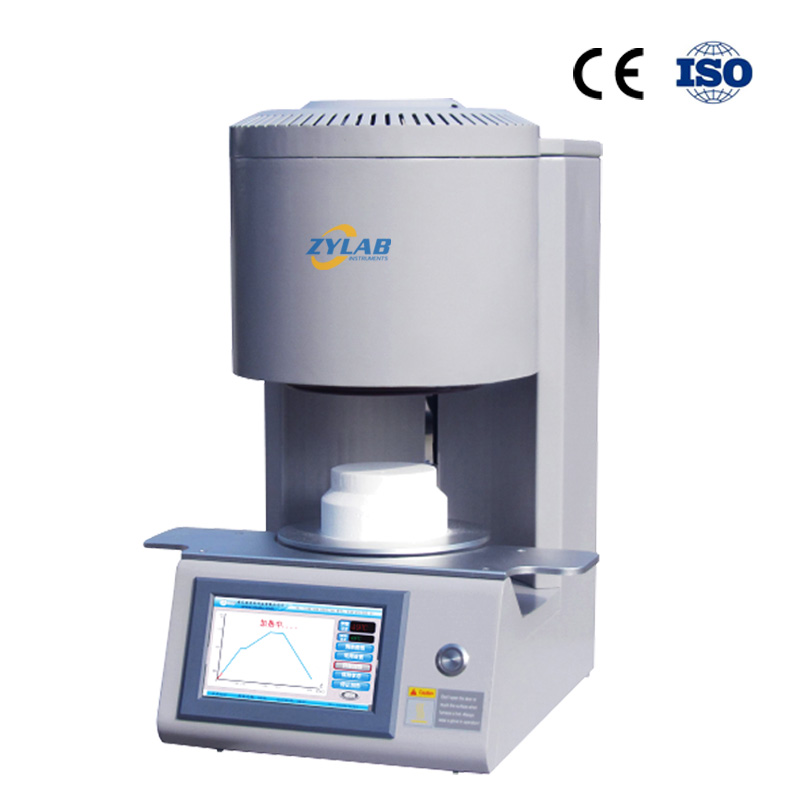

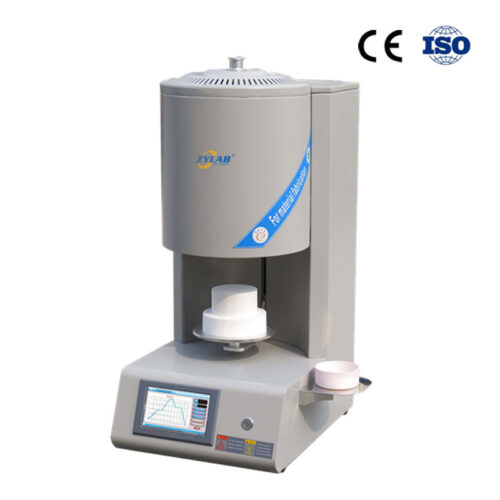

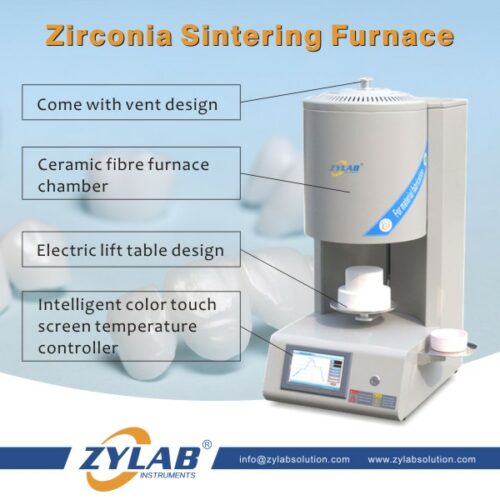

Professional Dental Lab Vacuum Porcelain Furnace

Introduction

ZYLAB Vacuum Porcelain Furnace is special designed for dental lab. It is an ideal dental equipment in dental lab for ceramic, nichrome, Ti-Cr alloy, stainless, zirconia dental crown and dental bridge etc pre-heating, roasting , sintering, glazing etc heat treatment.

Adopts international advanced manufacturing technology. Furnace cavity is high purity light weight alumina fiber material. The control interface is large color touch screen, easy to operate. Control mathematical model uses advanced PID self-learning fuzzy control, so that control accuracy is maintained at +/- 1.C. Its standardization production process ensures the quality and consistency of your sintering sample.

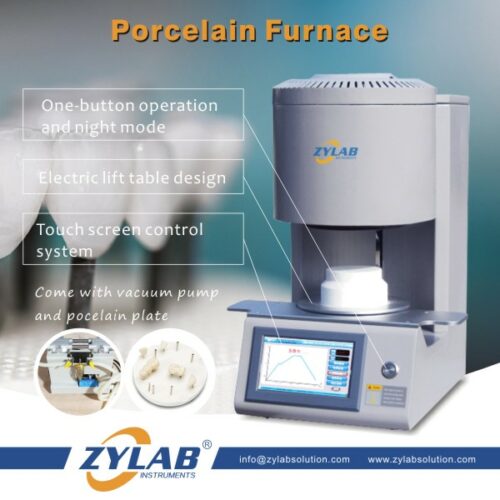

Features

- Heating elements surrounded, more constant temperature field.

- Electric lift table design, safe loading.

- Vertical structure is more compact, smaller space.

- Touch screen control system, more simple operation.

- PID temperature controller with high precision temperature accuracy.

- One-button operation and night mode, easy and convenient for operator.

- Low power consumable, suitable for all kinds of dental labs, factory.

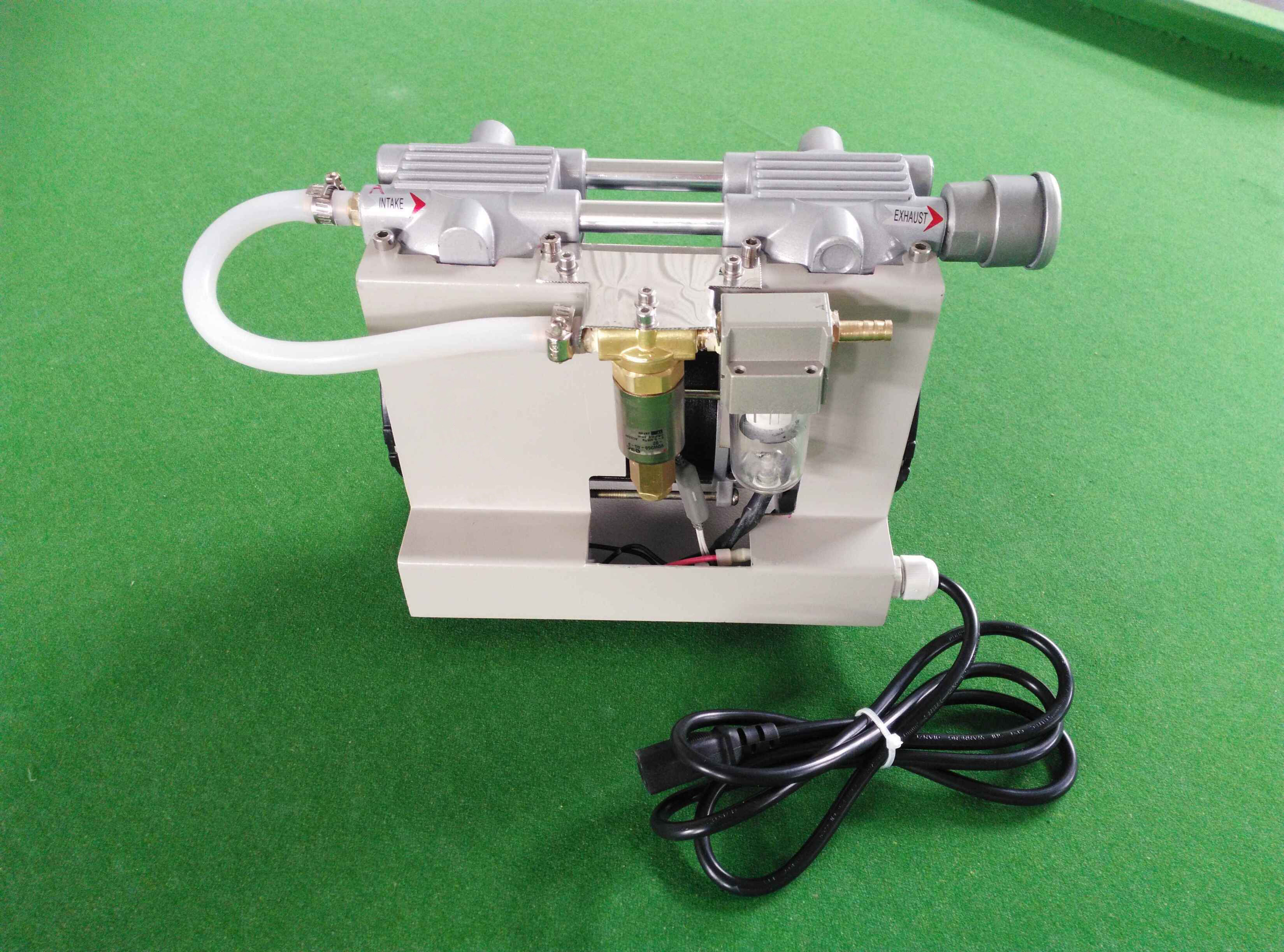

- Comes with a vacuum pump and porcelain firing tray, ready for immediate use.

Technical Parameters

| Model | B1200 -10IT Vacuum Porcelain Furnace |

|

Furnace structure |

•1430 type high purity ceramic fibre insulation (energy saving 40% and weight lighter about 30% than old furnace);

• Double layers steel casing with fan cooling, to ensure the surface of furnace below 50 oC. |

| Chamber size

(working space) |

Ø100x70mmmm (Diameter x Height) |

| Max. temperature | 1200 ℃(<1 hours) |

| Working temperature | Rt -1100 ℃ |

| Intelligent Touch Screen

Temperature controller |

•PID automatic control and auto-tune function.

•30 programmable segments for precise control. •Built in protection for over-heated and broken thermal couple, and leakage. • Centralized control 7” color LCD touch screen man-machine English graphics interface, clear heating process, more intuitive and convenient operation. •.Can store sintering programs to avoid the trouble caused by repeated settings of different experimental processes.

|

| Heating element | Top quality resistance wire with high-purity quartz tube as protective, which can effectively prevent cross-contamination between the heating body and the material. |

| Heating rate | 0-20℃/min |

| Temperature accuracy | +/- 1 ℃ |

| Vacuum degree | -97Kpa |

| Thermocouple | K type |

| Working voltage | AC 208 – 240V, 50/60 Hz (according to requirement) |

| Max. Power | 1.4Kw |

| Dimension | 410(L)*480(H)*410(D)mm |

| Quantity / Net weight | 1set / 30kgs |

| Warranty | 12 months(not including consumable parts such as heating elements, thermocouple), lifetime support. |

| Certified | CE, ISO9001 |

Applications of Vacuum Porcelain Furnace

The application of a porcelain furnace is primarily in the field of dentistry and dental laboratories for the fabrication of dental prosthetics and restorations. Here are some specific applications of a porcelain furnace:

Dental Crowns:

Porcelain furnaces are commonly used for the fabrication of dental crowns, which are tooth-shaped caps that are placed over damaged or decayed teeth. The furnace allows for the precise firing of porcelain materials, resulting in durable and aesthetically pleasing dental crowns that closely resemble natural teeth.

Dental Veneers:

Veneers are thin shells made of porcelain that are bonded to the front surface of teeth to improve their appearance. Porcelain furnaces are utilized to fire and shape the veneer materials, ensuring that they are strong, translucent, and have the desired color and texture.

Dental Bridges:

Porcelain furnaces play a crucial role in the production of dental bridges, which are used to replace missing teeth by attaching artificial teeth to adjacent natural teeth. The furnace allows for the precise firing of porcelain materials to create strong and natural-looking dental bridges that blend seamlessly with the patient’s existing teeth.

Inlays and Onlays:

Porcelain furnaces are used for fabricating inlays and onlays, which are indirect restorations that are used to repair damaged or decayed teeth. Inlays are placed within the tooth, while onlays cover a larger portion of the tooth. The furnace ensures the proper firing of the porcelain materials to create precise-fitting and durable inlays and onlays.

Dental Implants:

Porcelain furnaces are involved in the fabrication of ceramic components used in dental implant restorations. The furnace is used to fire and shape porcelain materials for the creation of implant crowns, abutments, and other prosthetic components, ensuring optimal fit, aesthetics, and function.

Benefits of Vacuum Porcelain Furnace

Porcelain furnaces offer several benefits in the field of dentistry and dental laboratory applications. Here are some key benefits of using a porcelain furnace:

Aesthetics:

Porcelain furnaces allow for the precise firing of porcelain materials, resulting in dental restorations that closely mimic the natural appearance of teeth. The furnace helps achieve optimal color matching, translucency, and texture, ensuring highly aesthetic and lifelike dental prosthetics.

Durability:

The controlled firing process in a porcelain furnace helps enhance the strength and durability of dental restorations. By eliminating porosities and ensuring proper densification of the ceramic materials, the furnace produces restorations that can withstand the forces of biting and chewing, resulting in long-lasting outcomes for patients.

Customization:

Porcelain furnaces come with programmable firing cycles, allowing dental technicians to customize the firing parameters based on the specific requirements of each dental restoration. This level of customization enables the creation of restorations tailored to the patient’s individual needs, ensuring a precise fit and optimal performance.

Consistency:

Porcelain furnaces provide consistent and reproducible results. The furnace’s ability to distribute heat evenly throughout the firing chamber ensures uniform firing of the ceramic materials, leading to consistent physical and mechanical properties in the dental restorations. This consistency is vital for reliable and predictable outcomes.

Precision:

Porcelain furnaces offer precise temperature control, allowing for accurate manipulation of firing parameters such as temperature, holding time, and cooling rates. This precision ensures that the ceramic materials undergo the desired chemical and physical transformations required for optimal aesthetics and mechanical properties.

Versatility:

Porcelain furnaces can accommodate a wide range of dental ceramic materials, including different types of porcelain, zirconia, and other ceramic compounds. This versatility allows dental professionals to choose the most suitable materials for each case, based on factors such as strength requirements, esthetics, and patient preferences.

Efficiency:

Modern porcelain furnaces are designed with advanced features that optimize energy consumption and minimize firing cycle times. This improves the overall efficiency of the dental laboratory, allowing for faster turnaround times and increased productivity.

FAQ of Vacuum Porcelain Furnace

Q1: What is the difference between a porcelain furnace and a vacuum porcelain furnace?

A1: The main difference between a porcelain furnace and a vacuum porcelain furnace lies in the operating environment. A standard porcelain furnace operates in an atmospheric environment, while a vacuum porcelain furnace operates under a controlled vacuum condition. The vacuum environment in a vacuum porcelain furnace offers benefits such as improved color stability, reduced porosity, enhanced control over the firing process, and the ability to achieve higher firing temperatures.

Q2: How does a porcelain furnace work?

A2: A porcelain furnace works by applying heat to dental ceramic materials, such as porcelain, to achieve their desired properties. The furnace consists of a chamber where the ceramic restorations are placed, and heating elements that generate and control the temperature inside the chamber. The firing process involves gradually increasing the temperature to a specific level and holding it for a certain period to allow for the desired changes in the ceramic material. This process, known as firing or sintering, helps the ceramic restorations reach their optimal density, hardness, and color stability.

Q3: What are the benefits of using a vacuum porcelain furnace?

A3: The use of a vacuum porcelain furnace offers several benefits. It provides enhanced control over the firing process, resulting in improved color stability and reduced discoloration of ceramic materials. Firing ceramics in a vacuum can also significantly reduce porosities, leading to increased strength and durability of the restorations. The vacuum environment allows for more homogeneous heating, ensuring even temperature distribution. Additionally, vacuum porcelain furnaces can accommodate higher firing temperatures, which can be advantageous for certain types of ceramic materials.

Q4: How does a vacuum porcelain furnace improve the quality of dental restorations?

A4: A vacuum porcelain furnace improves the quality of dental restorations by providing better control over the firing process and creating a controlled vacuum environment. This leads to improved color stability, reduced porosity, and enhanced strength of the ceramic restorations. The absence of air in the vacuum environment prevents oxidation, resulting in more natural-looking and aesthetically pleasing restorations. The vacuum condition also allows for more precise firing parameters, leading to consistent and reliable results.

Q5: How long can delivery?

A5: Normally, 3-7 days after confirming order. We have in stock, after testing and packing, will delivery at the first time.

More Solutions for Your Dental Laboratory

Please visit our website [Dental Laboratory Collection]