Introduction

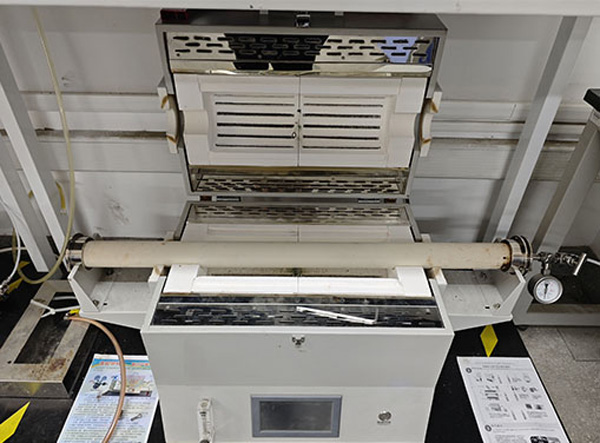

Material synthesis and thermal treatment are fundamental in developing nanomaterials, battery materials, ceramics, and other high-performance materials. The 1700°C Tube Furnace plays a critical role in these processes by providing precise temperature control, vacuum and atmosphere protection, and uniform heating.

This furnace is widely used in vacuum sintering, high-temperature annealing, and controlled atmosphere heat treatment, enabling researchers and manufacturers to optimize material properties for advanced applications.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Vacuum Sintering and Atmosphere Protection in Material Processing

1. Nanomaterials Synthesis

Nanomaterials require precise control over particle size, morphology, and purity. The 1700°C Tube Furnace enables:

- Vacuum sintering of nanostructures, reducing contamination and improving crystallinity.

- Controlled atmosphere processing to prevent oxidation and ensure stability.

- Rapid thermal treatment, essential for synthesizing carbon nanotubes, nanowires, and quantum dots.

- CVD (Chemical Vapor Deposition) and precursor decomposition, critical for functional nanomaterials.

2. Battery Material Processing

Battery performance depends heavily on the crystal structure and composition of electrode materials.The 1700°C Tube Furnace supports:

- High-temperature calcination of cathode and anode materials (e.g., LiCoO₂, LiFePO₄).

- Atmosphere-controlled sintering to optimize ion conductivity and electrochemical stability.

Vacuum treatment to remove volatile impurities, ensuring high-purity battery materials.Precise temperature ramping to tailor material microstructures for improved battery performance.

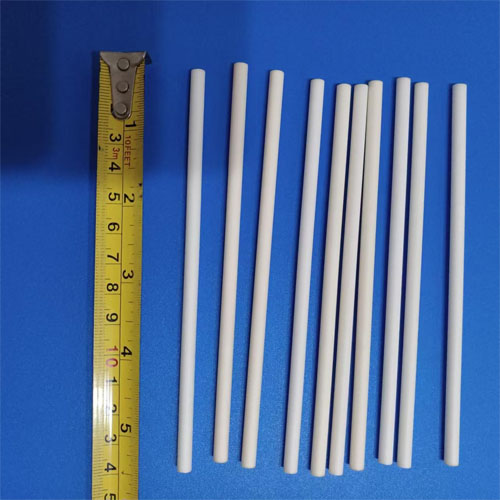

3. Advanced Ceramic Sintering

High-performance ceramics require controlled sintering conditions to achieve desired mechanical, thermal, and electrical properties. This furnace is ideal for:

- Vacuum sintering of technical ceramics, reducing defects and enhancing density.

- Controlled atmosphere processing for electronic ceramics (e.g., piezoelectric materials, capacitors).

- Synthesis of ultra-high temperature ceramics (UHTCs) for aerospace and industrial applications.

- Heat treatment of transparent ceramics, improving optical clarity and performance.

4. High-Performance Material Annealing & Sintering

Many advanced materials, including superalloys, composites, and semiconductor materials, require precise thermal processing. The 1700°C Tube Furnace is used for:

- Vacuum annealing to relieve stress and refine microstructures.

- Sintering in controlled gas atmospheres (e.g., nitrogen, argon, hydrogen) to prevent oxidation.

- Graphitization of carbon materials, crucial for conductive applications.

- Solid-state reactions, enabling the formation of complex material phases.

Why Choose ZYLAB 1700°C Tube Furnace?

ZYLAB’s 1700°C Tube Furnace combines cutting-edge technology, safety, and efficiency, making it an ideal choice for research institutes, universities, and industrial laboratories.

Its high precision, user-friendly interface, and reliable performance ensure that researchers and engineers achieve optimal results in their material preparation processes.

Conclusion

The 1700°C Tube Furnace is an indispensable tool in modern material science, offering high-temperature processing, precise control, and customizable atmosphere conditions.

Whether for nanomaterials, battery research, or high-performance ceramics, this furnace provides exceptional stability, efficiency, and safety for researchers and engineers worldwide.

By integrating advanced thermal control, superior insulation, and versatile functionalities, the ZYLAB 1700°C Tube Furnace stands out as an essential piece of equipment for cutting-edge material research and industrial applications.

For more information on Tube furnaces or to inquire about custom solutions, feel free to contact us.