When using a 1700°C high-temperature sintering furnace, it is essential to follow specific precautions to ensure safe and efficient operation. Here are some key precautions:

- Correctly placing the door block and closing the furnace door when the furnace is heating up. This can enhance safety, stabilize temperature control, and improve heating efficiency.

- Do not open the furnace chamber during high-temperature firing. This is not only dangerous but can also cause damage to the sample and equipment due to sudden temperature changes.

- After firing is complete, do not disconnect the power until the furnace temperature has dropped below 300°C. This prevents damage to the equipment from excessively high temperatures.

- When using the furnace for the first time or after a long period of inactivity, bake it at around 300°C for 2 hours before use. Ensure the furnace temperature does not exceed the rated temperature to avoid damaging the heating elements and furnace lining. Do not pour any liquids or dissolved metals directly into the furnace chamber to maintain cleanliness.

- The furnace uses silicon molybdenum rods as heating elements. Due to their high brittleness at room temperature, avoid unnecessary disassembly and movement of the furnace body after the heating elements are installed.

- The furnace absorbs a lot of heat when used cold, so avoid rapid heating in the low-temperature range. The heating rate difference across various temperature ranges should not be too large. When setting the heating rate, fully consider the physical and chemical properties of the sintered material to avoid material spillage and contamination of the furnace chamber.

- Regularly check the electrical connections of the temperature control system for good contact. Pay special attention to the tightness of all connection points of the heating elements.

- Avoid operating silicon molybdenum rods in the temperature range of 400-700°C for extended periods, as this can cause low-temperature oxidation of the elements.

- During operation, if the displayed temperature deviates from the programmed value around 500-600°C, check if the “P, I, D” parameters are set correctly.

- The furnace uses a Type B high-temperature double platinum-rhodium (30%-6%) temperature sensor. The instrument has a measurement accuracy of 0.5 grade at 0-600°C and 0.2 grade at 600-1700°C.

- The furnace is suitable for the following working conditions:

- Ambient temperature between -10°C and 75°C.

- Relative humidity not exceeding 85%.

- No conductive dust, explosive gases, or corrosive gases around the furnace.

- No significant inclination, vibration, or bumps.

By adhering to these precautions, you can ensure the safe and efficient operation of a 1700°C high-temperature sintering furnace, protecting both personnel and equipment.

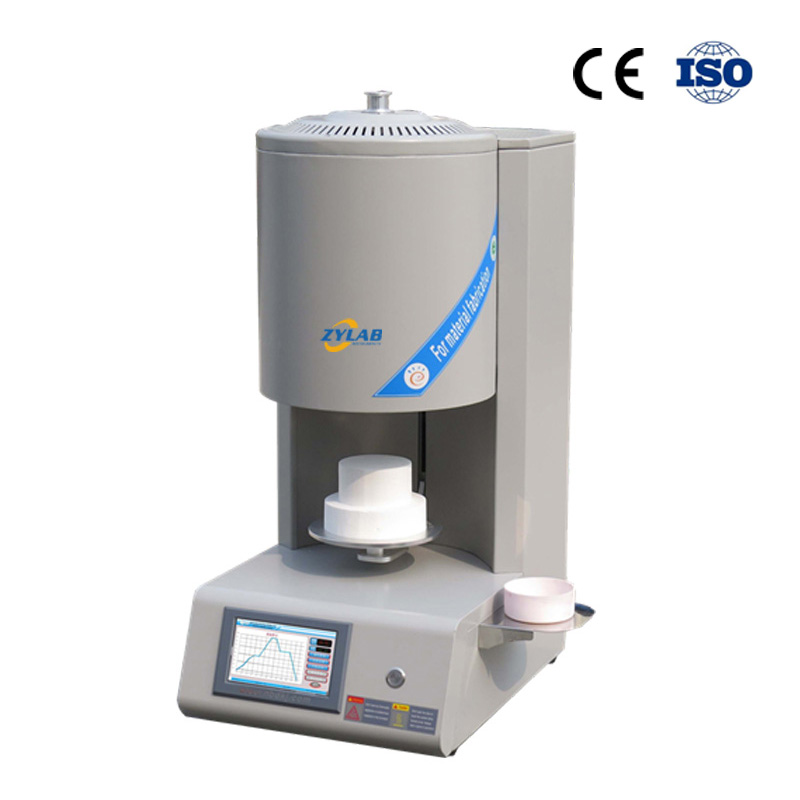

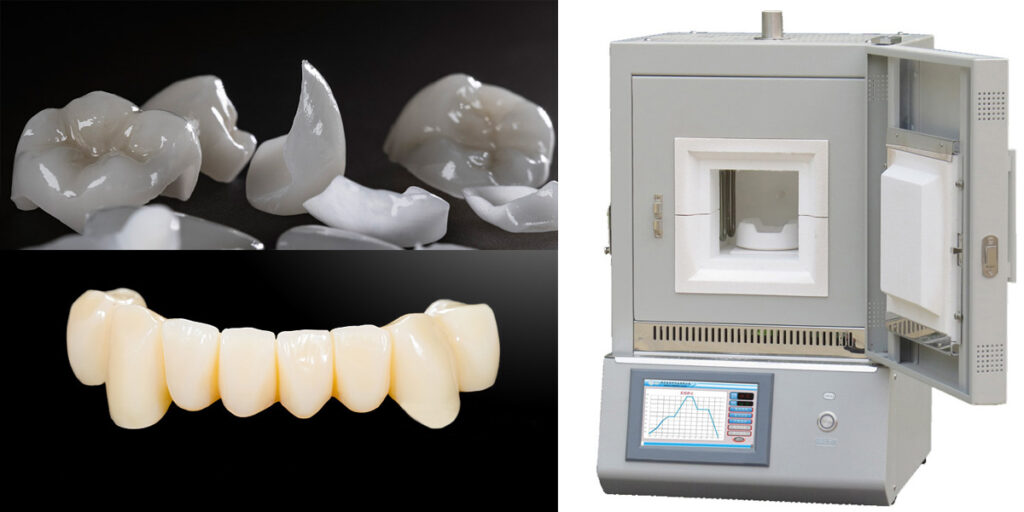

ZYLAB recommends the 1700°C high-temperature sintering furnace: