Table of Contents

Introduction

Nanomaterials have revolutionized multiple industries, from electronics and energy storage to biomedicine and catalysis. Their unique properties, such as high surface area, quantum effects, and enhanced mechanical strength, make them essential for cutting-edge applications.

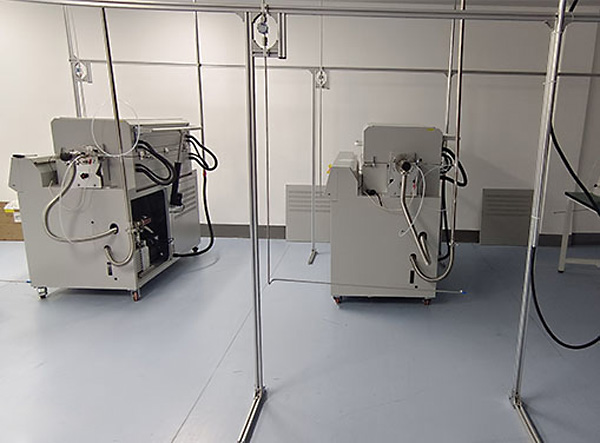

However, achieving precise control over the synthesis and modification of nanomaterials requires advanced thermal processing techniques. A 1500°C high vacuum tube furnace is a crucial tool in this field, offering a controlled high-temperature environment essential for fabricating high-purity nanomaterials with tailored properties.

Importance of High Vacuum Tube Furnaces in Nanomaterials Research

1. High-Purity Processing Environment

One of the most critical requirements in nanomaterials research is the ability to process materials in an ultra-clean environment.

ZYLAB 1500°C high vacuum tube furnace provides a vacuum level as low as 10^-5 Pa, effectively eliminating oxygen and other contaminants. This ensures that oxidation and unwanted chemical reactions are minimized, preserving the material’s intrinsic properties and enhancing performance.

2. Precise Temperature Control for Uniform Nanostructures

Temperature control is crucial in nanomaterials synthesis, as it affects particle size, crystallinity, and morphology. The advanced PID temperature control system in high vacuum tube furnaces enables precise multi-step heating profiles with minimal fluctuations. This ensures:

- Uniform grain growth

- Consistent material phase formation

- Reduction of defects in nanostructures

3. Support for Multiple Gas Atmospheres

Apart from vacuum conditions, the high vacuum tube furnace allows for controlled atmospheres, including inert gases (argon, nitrogen), reducing gases (hydrogen), and reactive gases. This versatility enables various nanomaterial synthesis techniques such as:

- CVD (Chemical Vapor Deposition) for graphene, carbon nanotubes, and nanowires

- Sintering and Annealing of metal and ceramic nanoparticles

- Controlled Oxidation & Reduction for tuning nanomaterial properties

4. Rapid Heating and Cooling Capabilities

The use of high-efficiency silicon carbide heating elements allows for fast heating rates, reducing overall processing time and increasing throughput.

Additionally, controlled cooling profiles prevent thermal stress and unwanted phase transitions, which is particularly important for delicate nanostructures.

5. Scalability and Reproducibility

Research and industrial applications require not only precise material control but also repeatability and scalability.

The programmable temperature and atmosphere control of a high vacuum tube furnace ensures reproducible results, making it an ideal choice for both fundamental research and pilot-scale production of nanomaterials.

Applications in Nanomaterials Research

Graphene and Carbon Nanotubes (CNTs): High-temperature vacuum furnaces enable CVD-based synthesis of high-purity graphene and CNTs for applications in electronics, batteries, and composite materials.

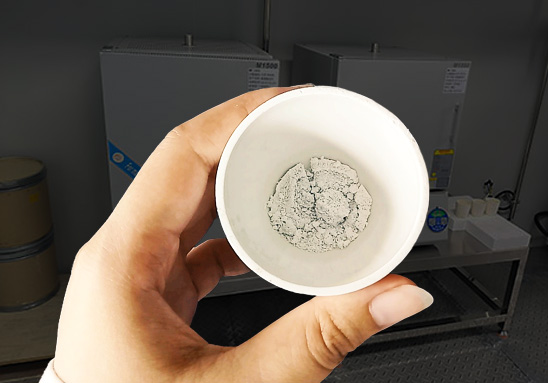

Metal Oxide Nanoparticles: Vacuum sintering and controlled oxidation processes are essential for producing metal oxide nanomaterials used in sensors, catalysis, and coatings.

Quantum Dots and Semiconductor Nanomaterials: Precise thermal treatment enhances crystal quality and electronic properties, improving their application in solar cells and optoelectronics.

Energy Storage Materials: High vacuum annealing is used to optimize electrode materials for lithium-ion batteries and supercapacitors.

Conclusion

For researchers in nanomaterials, ZYLAB’s 1500°C High Vacuum Tube Furnace provides the precise environmental control necessary for advanced material synthesis. Its high-temperature capability, superior vacuum performance, and customizable gas atmosphere make it an indispensable tool in modern nanotechnology research.

By leveraging this state-of-the-art equipment, scientists can develop next-generation nanomaterials with enhanced properties for electronics, energy, and biomedical applications.

For more details on how ZYLAB furnaces can support your research, contact us today!

Share this entry

You might also like