In industrial applications, particularly in the fields of powder metallurgy and ceramic manufacturing, high-temperature furnaces are essential for achieving optimal material properties.

Among these, the 1200°C vacuum hot press furnace plays a critical role in two key processes: metal powder densification and ceramic material sintering.

What is a 1200°C Vacuum Hot Press Furnace?

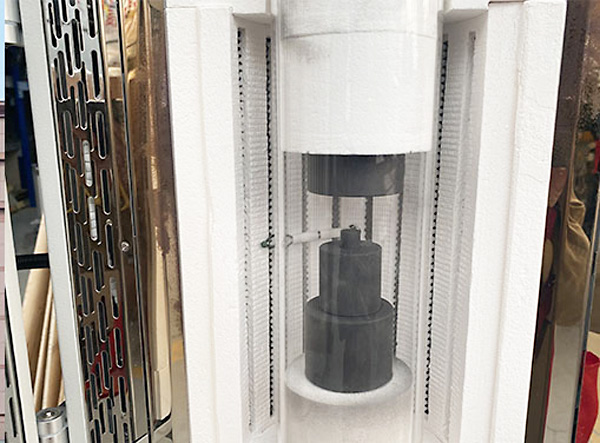

A 1200°C Vacuum Hot Press Furnace is a high-temperature furnace designed for precise heating and pressing in a controlled vacuum environment. It integrates both heat and pressure to ensure that materials undergo effective densification or sintering under the best possible conditions.

This furnace operates at temperatures up to 1200°C, which is suitable for many metal and ceramic processing applications.

The Role in Metal Powder Densification

Metal powder densification is an essential step in powder metallurgy, where metal powders are subjected to heat and pressure to form solid, compact materials. This process is known as Hot Isostatic Pressing (HIP) or Hot Pressing when done in a vacuum atmosphere.

- Enhanced Density and Strength: When metal powders are subjected to the controlled temperature and pressure in a 1200°C vacuum furnace, the particles bond together, increasing the overall density of the material. This reduces porosity and enhances the mechanical strength of the final product, making it suitable for high-performance applications like aerospace and automotive parts.

- Precise Control of Atmosphere: The vacuum environment within the furnace ensures that oxidation and contamination are minimized. This is particularly critical for metals like titanium, aluminum, and other reactive metals, which can be adversely affected by exposure to oxygen or other atmospheric gases during the densification process.

- Improved Material Properties: The vacuum hot pressing process helps in achieving uniform material properties, such as thermal conductivity and tensile strength, which are essential for the reliability of metal components in industrial applications.

The Role in Ceramic Material Sintering

Ceramic materials require a different but equally critical treatment for shaping and densification: sintering. The vacuum hot press furnace plays a pivotal role in achieving high-quality sintered ceramics.

- Effective Sintering of Ceramics: Sintering is a process where ceramic powders are heated to a temperature where particles bond together to form a solid piece. The 1200°C vacuum furnace provides precise control of temperature and atmosphere, ensuring that the ceramic material undergoes uniform sintering, achieving the desired density and mechanical properties.

- Minimizing Defects: Ceramics are particularly susceptible to defects such as cracking, warping, and unwanted phase transformations. The vacuum atmosphere of the furnace reduces the risk of these defects by controlling the partial pressure of gases like oxygen, which can cause unwanted reactions in the ceramic material.

- High-Temperature Sintering for Advanced Ceramics: For advanced ceramics, such as those used in electronics, medical devices, or aerospace components, sintering at higher temperatures, up to 1200°C, is often necessary to ensure the material’s structural integrity and functionality. The vacuum environment allows for precise control, ensuring the desired microstructure is achieved without contamination.

Case Study

A prestigious university, committed to academic excellence and industrial empowerment, recently purchased a 1200°C vacuum hot press furnace from ZYLAB. This strategic investment has catalyzed research across various disciplines, from the preparation of high-strength lightweight alloys needed in aerospace to optimizing ceramic-based thermal management materials crucial to the electronic chip industry.

Several research teams have redefined their experimental setups around this furnace, allowing both faculty and students to manipulate atomic arrangements and molecular fusion at the microscopic level. This has accelerated the transition of their innovative findings from the lab to the production line, contributing not only to the university’s academic reputation but also to the growth of high-tech industries.

Why Choose the 1200°C Vacuum Hot Press Furnace?

- Versatility: The 1200°C vacuum furnace is highly versatile, offering the ability to process both metal powders and ceramic materials. This makes it an ideal choice for industries that require multiple material types to be processed using the same equipment, reducing overall operational costs.

- Energy Efficiency: With precise temperature control, these furnaces reduce energy consumption by minimizing heat loss and ensuring that the material receives consistent heating throughout the process.

- High-Quality End Products: By operating under vacuum, the furnace ensures that the final products are free from contaminants and possess superior material properties, such as increased density, strength, and durability.

- Customization Options: Depending on the specific needs of the material or application, the vacuum furnace can often be customized with different pressure ranges, heating profiles, and atmosphere control systems to meet the requirements of various industrial processes.

Applications of 1200°C Vacuum Hot Press Furnace

- Metal Powder Densification: Used for parts in aerospace, automotive, electronics, and energy industries where high-performance materials are needed.

- Ceramic Sintering: Ideal for sintering advanced ceramics for use in medical devices, electronics, automotive components, and cutting-edge technologies.

- Powder Metallurgy: For manufacturing strong, reliable, and cost-effective metal components.

- Material Development: In research and development environments where new materials are being explored for diverse industrial applications.

Conclusion

The 1200°C Vacuum Hot Press Furnace is a powerful tool for both metal powder densification and ceramic material sintering. Its ability to operate under high pressure and in a controlled vacuum environment allows for precise material treatment, leading to enhanced material properties and reduced defects.

For industries relying on the highest quality metals and ceramics, investing in a high-performance vacuum furnace is essential to achieving desired results.

If you’re looking to enhance the quality and performance of your metal or ceramic products, consider the value that a 1200°C vacuum hot press furnace can bring to your operations.

For more information or technical support, feel free to contact ZYLAB.

Share this entry

You might also like